Multifunctional furring brick

A multi-functional, veneer brick technology, used in fire-resistant coatings, covering/lining, construction, etc., can solve the problems of high production cost and difficult construction, and achieve the effect of low product cost, easy popularization and application, and fast operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

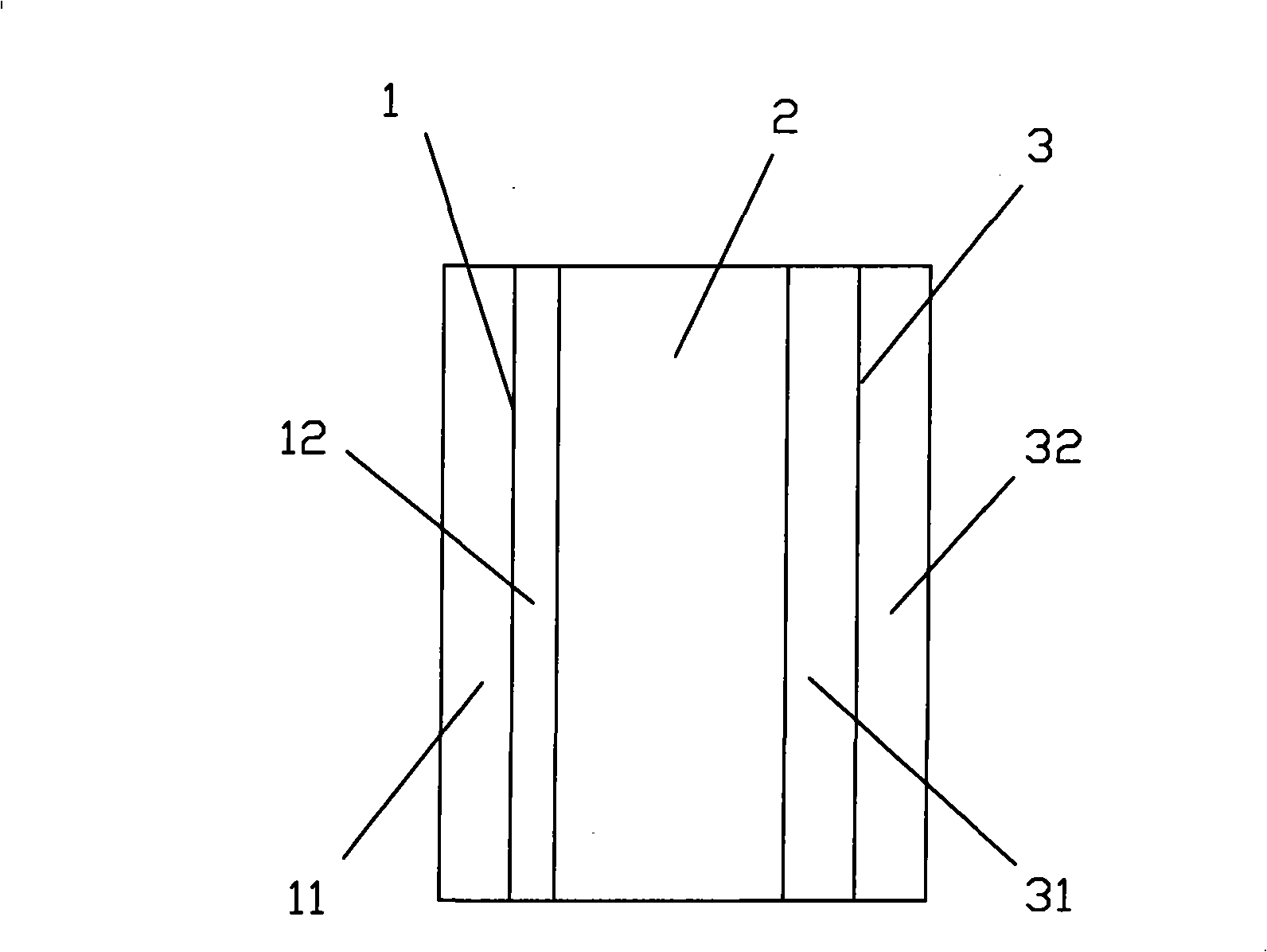

[0061] Embodiment one, see figure 1 As shown, a multifunctional veneer brick of the present invention is composed of a facing layer 1, a multifunctional layer 2, and an adhesive layer 3, and the facing layer 1 and the adhesive layer 3 are respectively made on the upper and lower surfaces of the multifunctional layer 2. two sides;

[0062] The adhesive layer 3 includes a first transition layer 31 and a high-grade cement mortar layer 32, the thickness of which is no more than 5 mm. The first transition layer 31 is first made on the contact surface of the multifunctional layer 2, and the high-grade cement mortar layer 32 is then made on the On the first transition layer 31; the first transition layer 31 is formed after the first working surface of the multi-functional layer 2 is dried by direct spraying or smearing of the first transition slurry; the first transition slurry comprises the following components and parts by weight: Elastic Acrylic Emulsion 85, Phthalyl Dioctyl 4.3,...

Embodiment 2

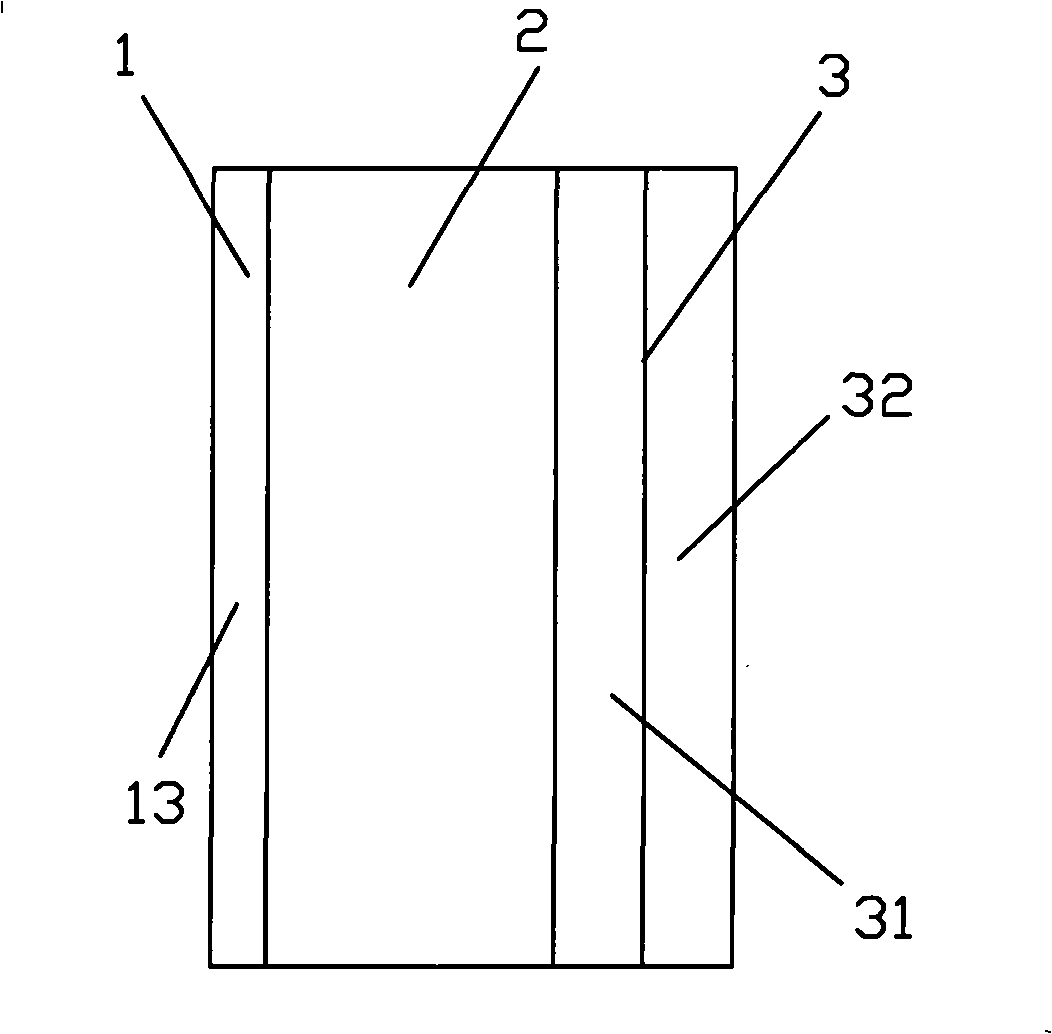

[0066] Embodiment 2, a multifunctional veneer brick of the present invention is composed of a facing layer 1, a multifunctional layer 2, and an adhesive layer 3, and the facing layer 1 and the adhesive layer 3 are respectively made on the upper and lower layers of the multifunctional layer 2. On the next two faces; the difference with embodiment one is that the second transition slurry of the second transition layer 12 includes the following components and parts by weight: elastic acrylate emulsion 95, dioctyl phthalate 5 , superplasticizer 1,325 # Or 40 of 425# ordinary Portland cement, 50 of 80-mesh silica sand, 50 of 200-mesh quartz sand, 35 of 300-mesh heavy calcium powder, and appropriate amount of water.

Embodiment 3

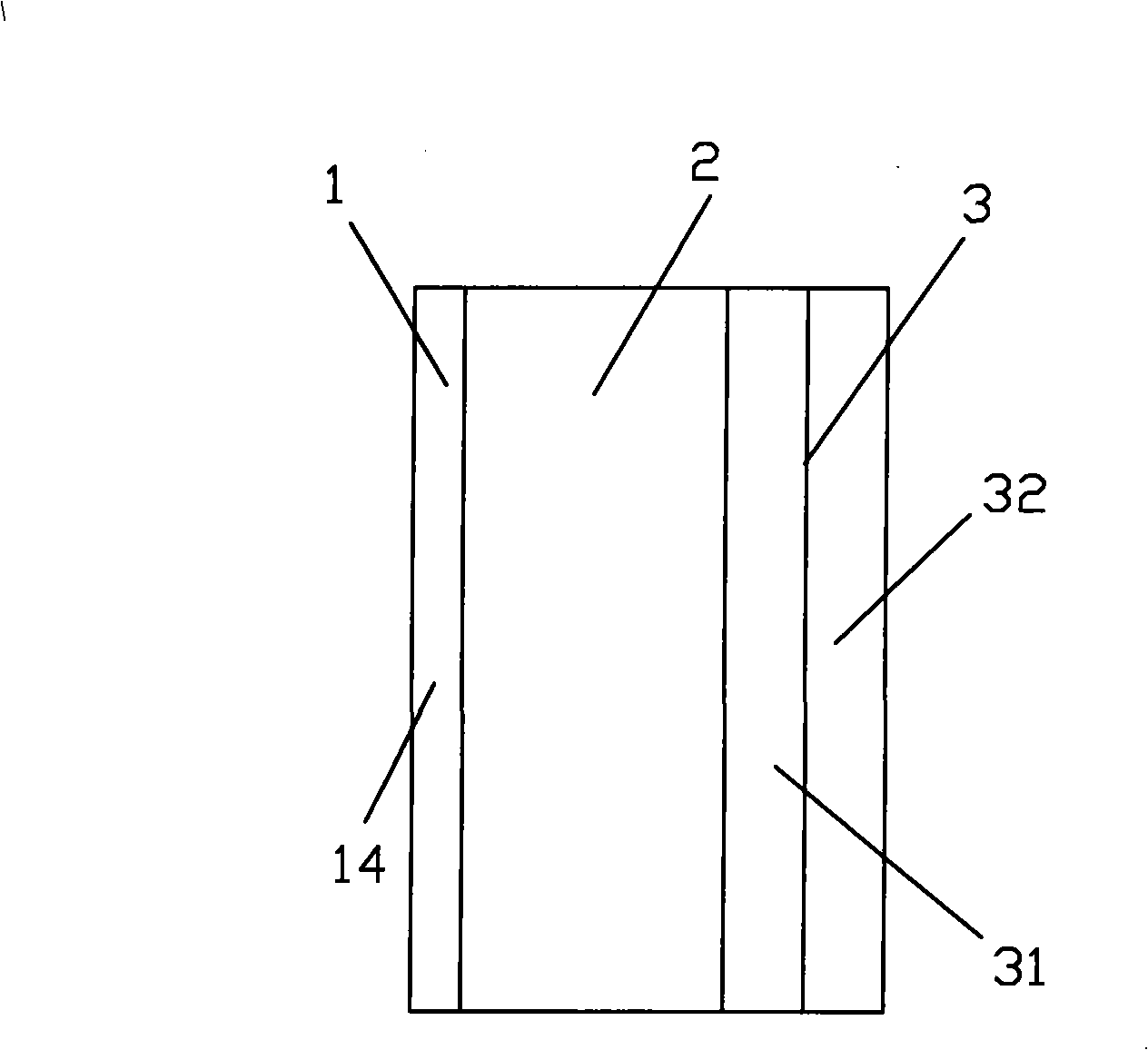

[0067] Embodiment 3, a kind of multifunctional veneer brick of the present invention is made of facing layer 1, multifunctional layer 2, bonding layer 3, and facing layer 1 and bonding layer 3 are made on the top of multifunctional layer 2, respectively. On the next two faces; the difference with embodiment one is that the second transition slurry of the second transition layer 12 includes the following components and parts by weight: elastic acrylate emulsion 115, dioctyl phthalate 4 , superplasticizer 0.1, 325 # Or 60 of 425# ordinary Portland cement, 60 of 80 mesh silica sand, 50 of 200 mesh quartz sand, 20 of 300 mesh heavy calcium powder, and appropriate amount of water.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com