Flush door

A door frame and door leaf technology applied to flush doors. It can solve the problems of difficult to guarantee thermal insulation performance, difficult installation of doors and unreasonable structure, etc., to achieve good thermal insulation and wind pressure resistance, meet the requirements of use, and improve the effect of sealing performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] In order to further understand the invention content, characteristics and effects of the present invention, the following examples are given, and detailed descriptions are as follows in conjunction with the accompanying drawings:

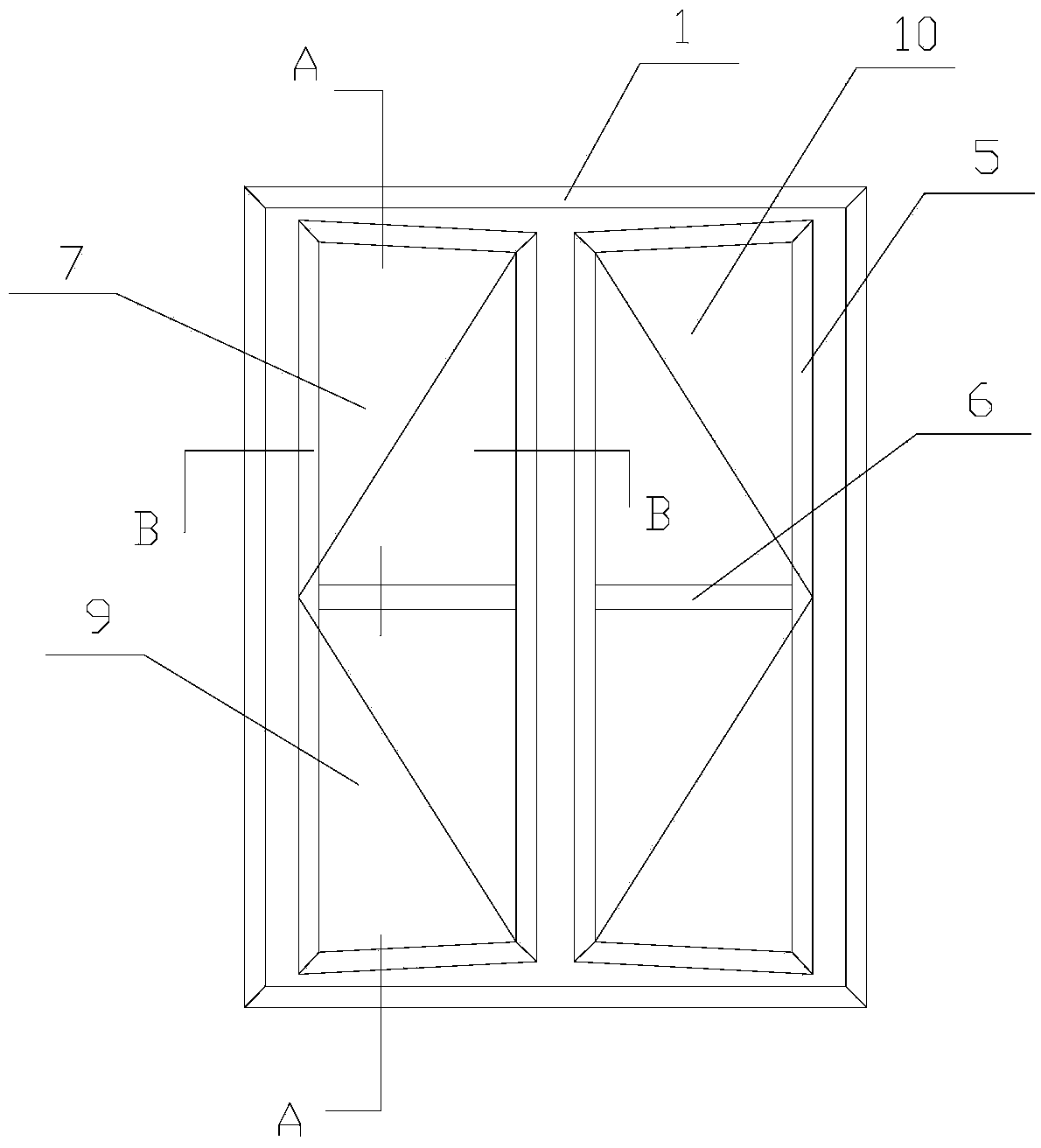

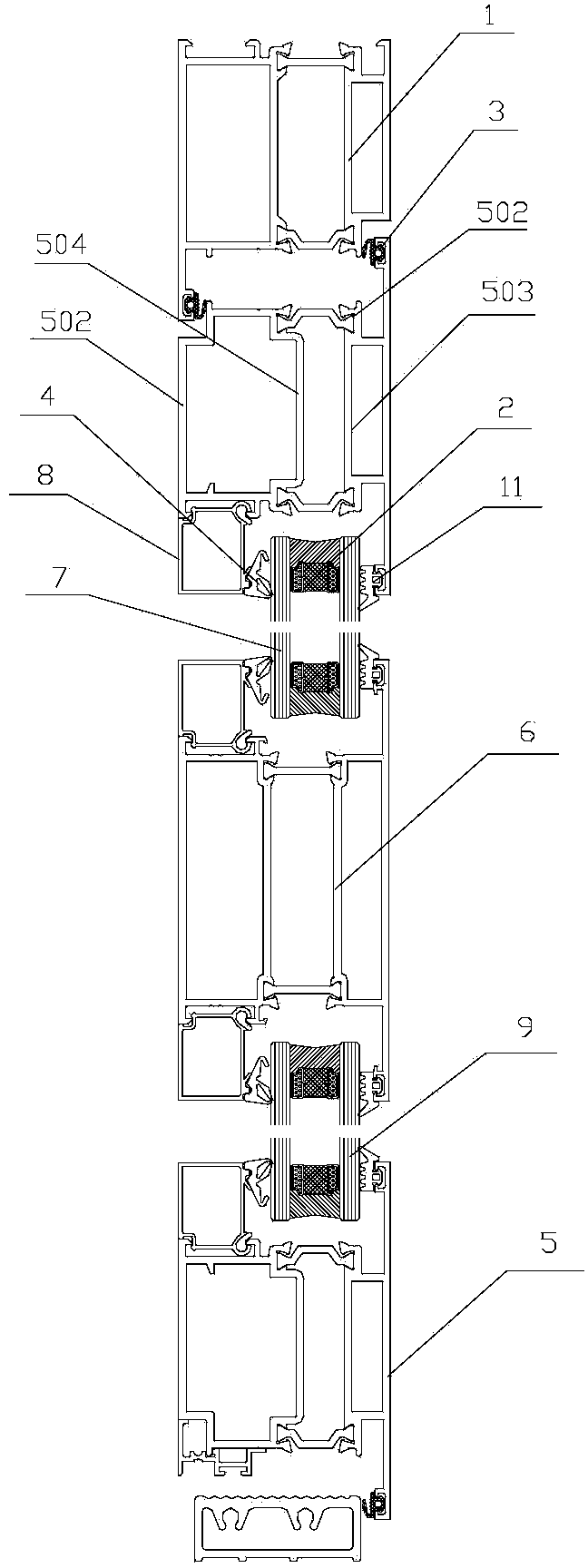

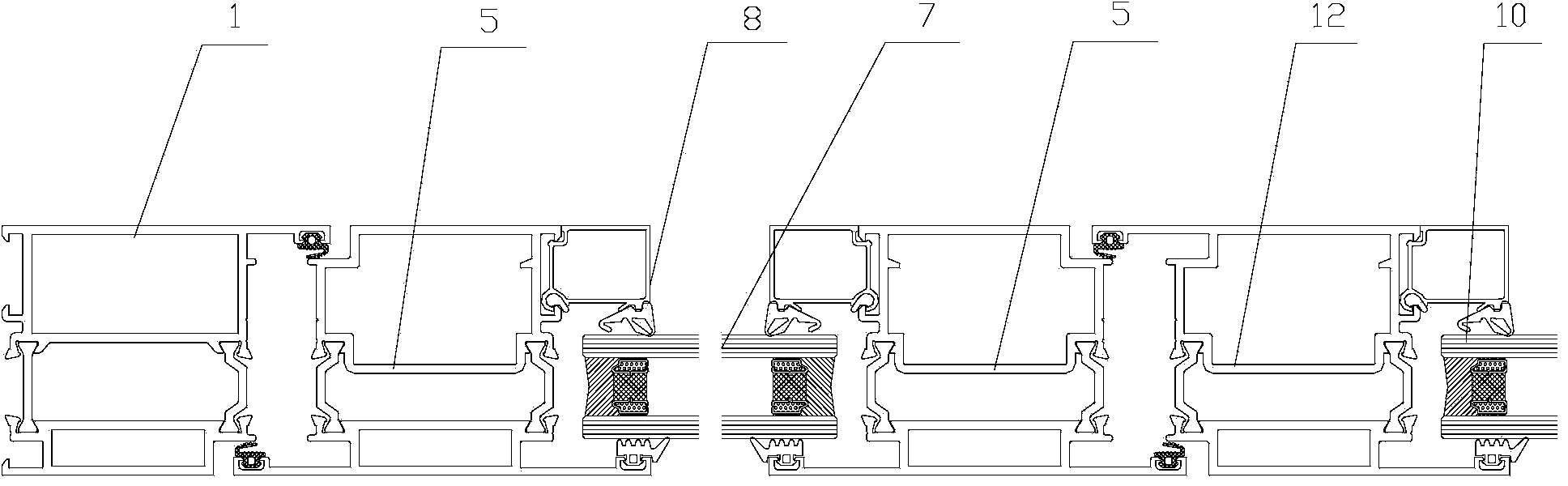

[0013] See figure 1 with figure 2 , Figure 4 , a flush door, comprising an outward-swinging door frame 1, an outward-swinging door leaf 5, glass and a door stile 6, the outward-swinging door frame 1 and the door stile 6 are interconnected to form a frame structure of the door. A heat insulating strip 3 is provided at the joint between the outwardly opening door frame 1 and the outwardly opening door leaf 5 , and a bending section 301 is provided at the place where the heat insulating strip 3 extends outward. Two pairs of dovetail-shaped grooves 501 corresponding to each other are arranged on the inner surface of the outward-opening door leaf 5. The groove 501 is sunken inward, and a protrusion 504 is arranged between the two dovetail-sha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com