Convex vacuum thermal baffle and manufacturing method thereof

A technology of vacuum insulation board and insulation board, which is used in building components, thermal insulation, climate change adaptation and other directions, can solve problems such as poor thermal insulation performance, burning drippings, secondary fires, etc., to increase the sealing area and air tightness. Effect of layer thickness, enhanced adhesion and adhesion strength, improved productivity and yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0110] The present invention also provides a method of manufacturing a convex vacuum insulation panel with a vacuum layer, comprising:

[0111] The first step, the preparation of the mold: according to the shape and size of the convex vacuum insulation panel to be produced, the production mold of the convex insulation panel is prepared;

[0112] When the heat insulation board is a glass plate, make the hot bending mold in the existing hot bending glass preparation technology;

[0113] When the heat insulation board is a ceramic board, the stamping die or grouting die in the existing ceramic board preparation technology is made;

[0114] When the heat insulation board is a metal plate, the stamping die in the existing metal plate preparation technology is made;

[0115] The second step, the production of the convex heat insulation board: use the mold to prepare the convex heat insulation board;

[0116] When the heat insulation board is a glass plate, prepare a flat glass pla...

Embodiment 1

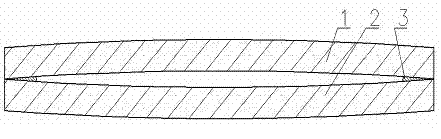

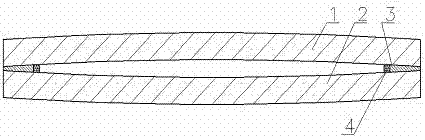

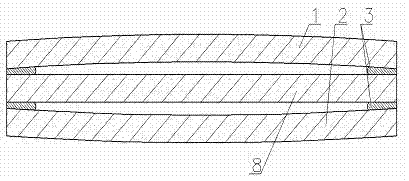

[0149] Embodiment 1: see figure 1 , the vacuum insulation panel is composed of an upper convex glass insulation panel 1 and a lower convex glass insulation panel 2, one of which is a low-emissivity glass coated with aluminum film, and the peripheries of the two insulation panels are welded together by low-temperature glass solder 3 Together, the middle is a vacuum layer. The production method is as follows: first, prepare two pieces of flat glass of the required size according to the shape and size of the vacuum insulation panel to be produced, and perform edge grinding, chamfering, cleaning and drying; secondly, put the two glass plates into the mold, place In the hot bending furnace, the temperature is raised to 550-750°C, which is the softening temperature of the glass, and the glass plate is formed into a convex surface by the gravity of the glass itself, and the glass plate is lowered to room temperature with the furnace; Coat the low-temperature glass solder, leave seve...

Embodiment 2

[0150] Example 2: see figure 1 , the vacuum heat insulation board is composed of an upper convex ceramic heat insulation board 1 and a lower convex ceramic heat insulation board 2, the periphery of the two heat insulation boards is welded together by a high-temperature ceramic glaze 3, and the middle is a vacuum layer. The production method is as follows: firstly, a metal stamping mold is prepared according to the shape and size of the vacuum insulation panel to be produced; secondly, the raw materials for making the ceramic insulation panel are loaded into the mold, and pressurized and formed by a press, and the mold is opened to obtain a ceramic insulation panel. The body of the plate is dried in a dryer; again, the two sides or one side of the body of the two ceramic plates and the periphery of the welding surface are evenly coated with high-temperature ceramic glaze, and several glazes are evenly left on the peripheral glaze on the welding surface. Air extraction holes, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com