Rubber rod for secondary processing of plastic pipe and secondary processing process of plastic pipe

A technology for secondary processing and plastic pipes, applied in the field of plastic pipe processing, can solve the problems of high production cost, depression, flattened surface of pipes, etc., and achieve the effect of improving flatness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

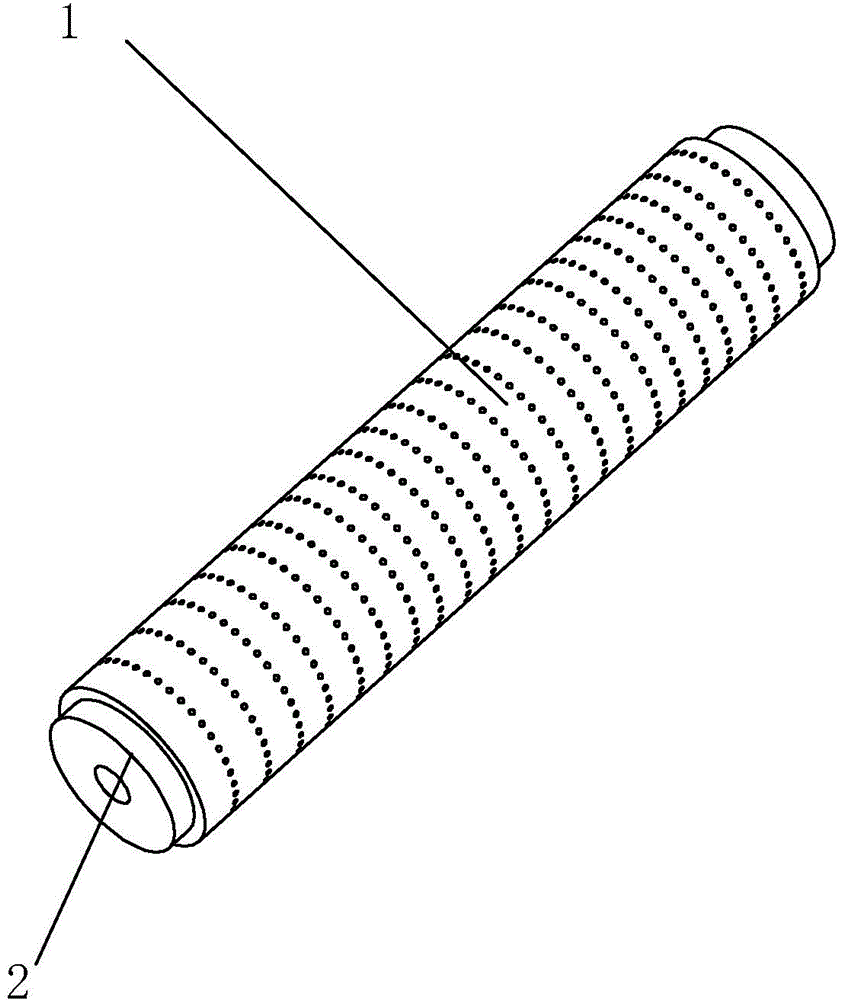

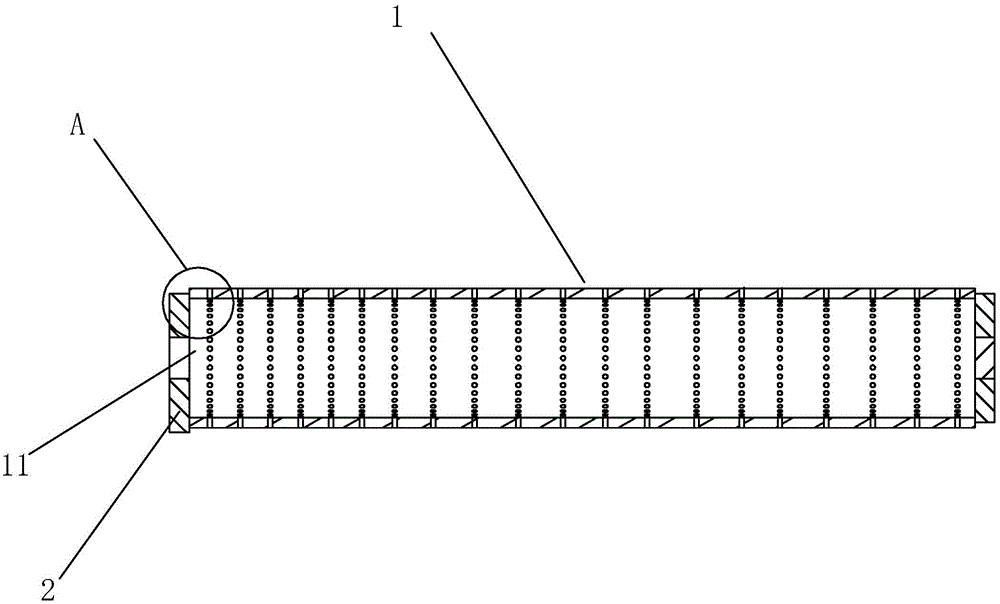

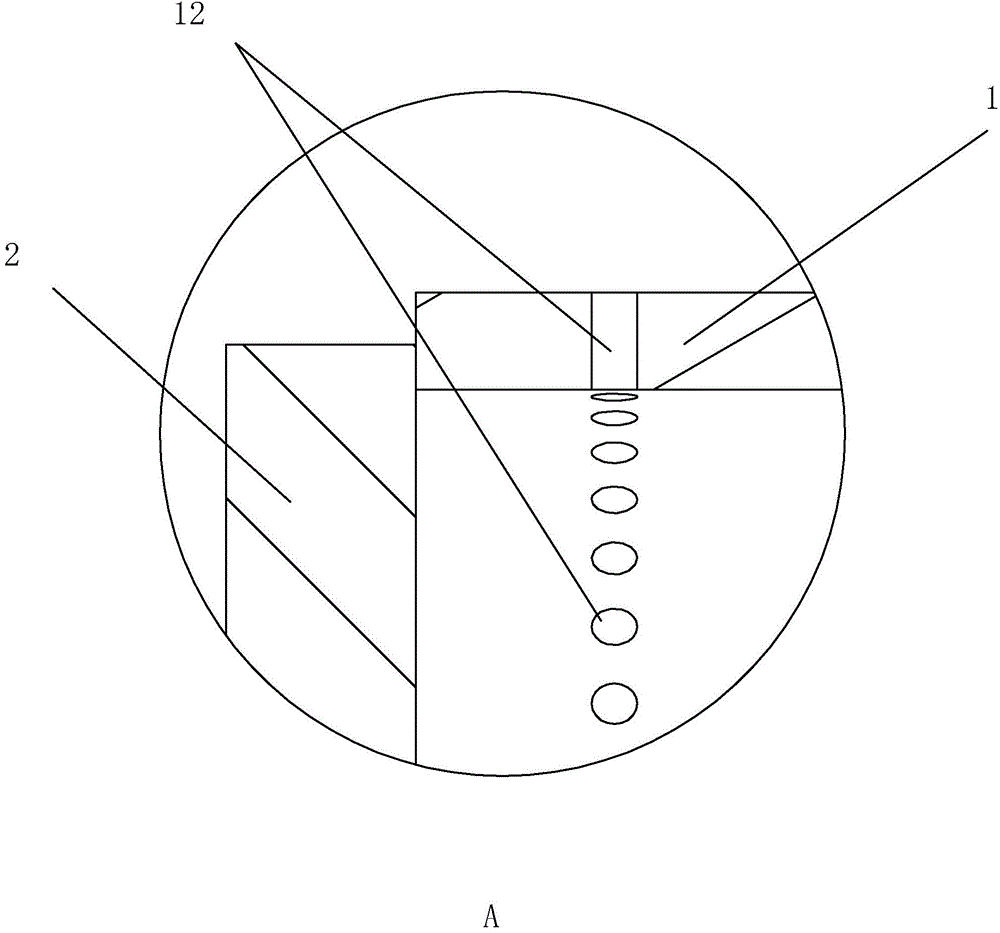

[0023] refer to Figure 1 to Figure 5 The embodiment of the rubber rod for secondary processing of plastic pipes and the secondary processing technology of plastic pipes of the present invention will be further described.

[0024] A plastic pipe secondary processing technology: select the rubber rod body 1 and the pipe 3 that needs to be bent, the present invention preferably makes the difference between the outer diameter of the rubber rod body 1 and the inner diameter of the pipe 3 be 2-5mm, when the inner diameter difference is 5mm , the rubber rod body 1 is easy to insert into the pipe, but the rubber rod body 1 needs to have a large amount of expansion, so that more air needs to be rushed in. When the inner diameter difference is 2mm, although it is easy to reach the rubber The rod body 1 expands to the required size, but when the rubber rod body 1 is inserted into the inside of the pipe, it is relatively difficult to plug. The preferred inner diameter difference of the p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com