Novel micro-channel heat exchanger

A micro-channel heat exchanger and a new type of technology, applied in the field of heat exchange, can solve the problems of insufficient heat exchange and low heat exchange efficiency, and achieve the effects of improving heat exchange efficiency, facilitating heat exchange, and being easy to form.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

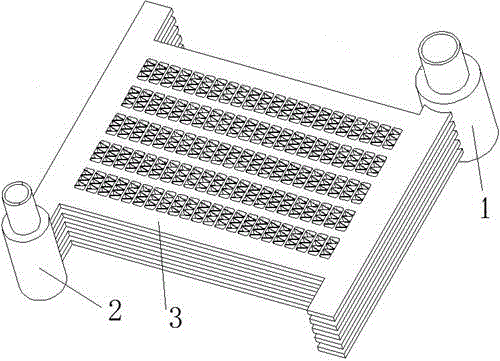

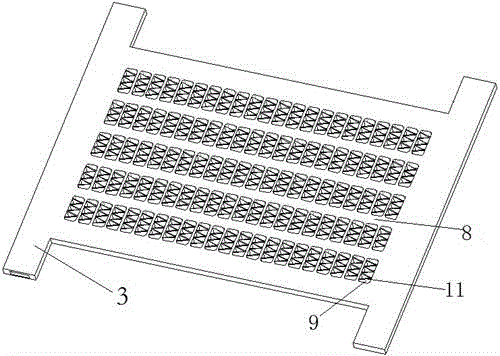

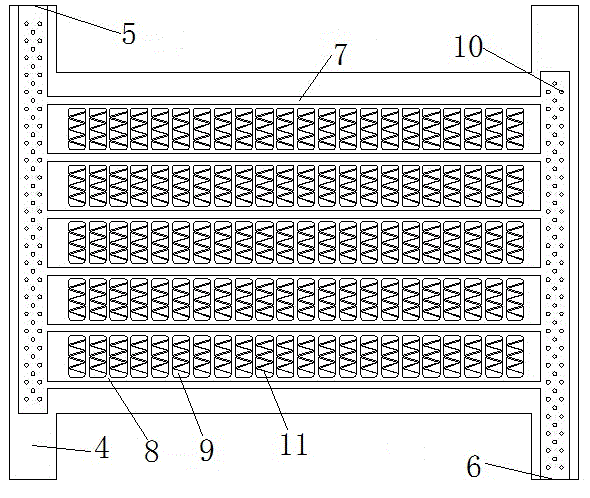

[0036] Such as Figure 1-Figure 5 As shown, a microchannel heat exchanger described in this embodiment includes a first header 1, a second header 2, and the first header 1 and the second header A heat exchange assembly connected by pipes 2, the heat exchange assembly includes several heat exchange units 3, such as figure 2 and image 3 As shown, the heat exchanging unit 3 includes two heat exchanging fins 4 that are butted together as a whole, and a concave groove is formed on the butt joint surface of the heat exchanging fins 4 , and after the butt joint faces of the two heat exchanging fins 4 are abutted, , the butted concave groove forms a fluid channel, and the flow channel includes an inlet channel 5, an outlet channel 6, and several intermediate channels 7 connecting the inlet channel 5 and the outlet channel 6, in this embodiment Among them, the middle passage 7 is set to 6; the heat exchange fin 4 is also provided with a number of molded between two adjacent middle ...

Embodiment 2

[0045] Such as Figure 6 As shown, as a transformable embodiment of embodiment 1, the differences between this embodiment and embodiment 1 are:

[0046] The joints between each end point of the "V"-shaped sheet and the adjacent fins 7 are formed in an arc shape.

Embodiment 3

[0048] Such as Figure 7 As shown, as a transformable embodiment of embodiment 1, the differences between this embodiment and embodiment 1 are:

[0049] The auxiliary fins 11 include a number of "V"-shaped fins arranged in rows or columns in the ventilation groove 9 and arranged at intervals. The auxiliary fins 11 are simple in structure and easy to form, and the sheet structure is convenient for sufficient heat exchange between the fluid and the heat exchange, and the ends of the two arms of the "V"-shaped sheet are connected to the adjacent fins 8 , so that the heat of the fluid in the middle channel 7 can be quickly transferred to the auxiliary fins 11 through the fins 8 .

[0050] Wherein, the auxiliary fins 11 also have some preferred dimensions, for example, the spacing S1 between two adjacent auxiliary fins 11 is not greater than 2 mm, and the thickness S2 of the auxiliary fins 11 is not greater than 0.5 mm. The included angle α of the auxiliary fins is not greater th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Hydraulic diameter | aaaaa | aaaaa |

| Inner wall diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com