Unplugging-free freezer

A freezer and freezer tube technology, applied in the freezer field, can solve the problems of large energy consumption of the soil, economic loss, freezer breakage, etc., and achieve the effects of reducing engineering costs, reducing engineering risks, and strong low-temperature ductility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

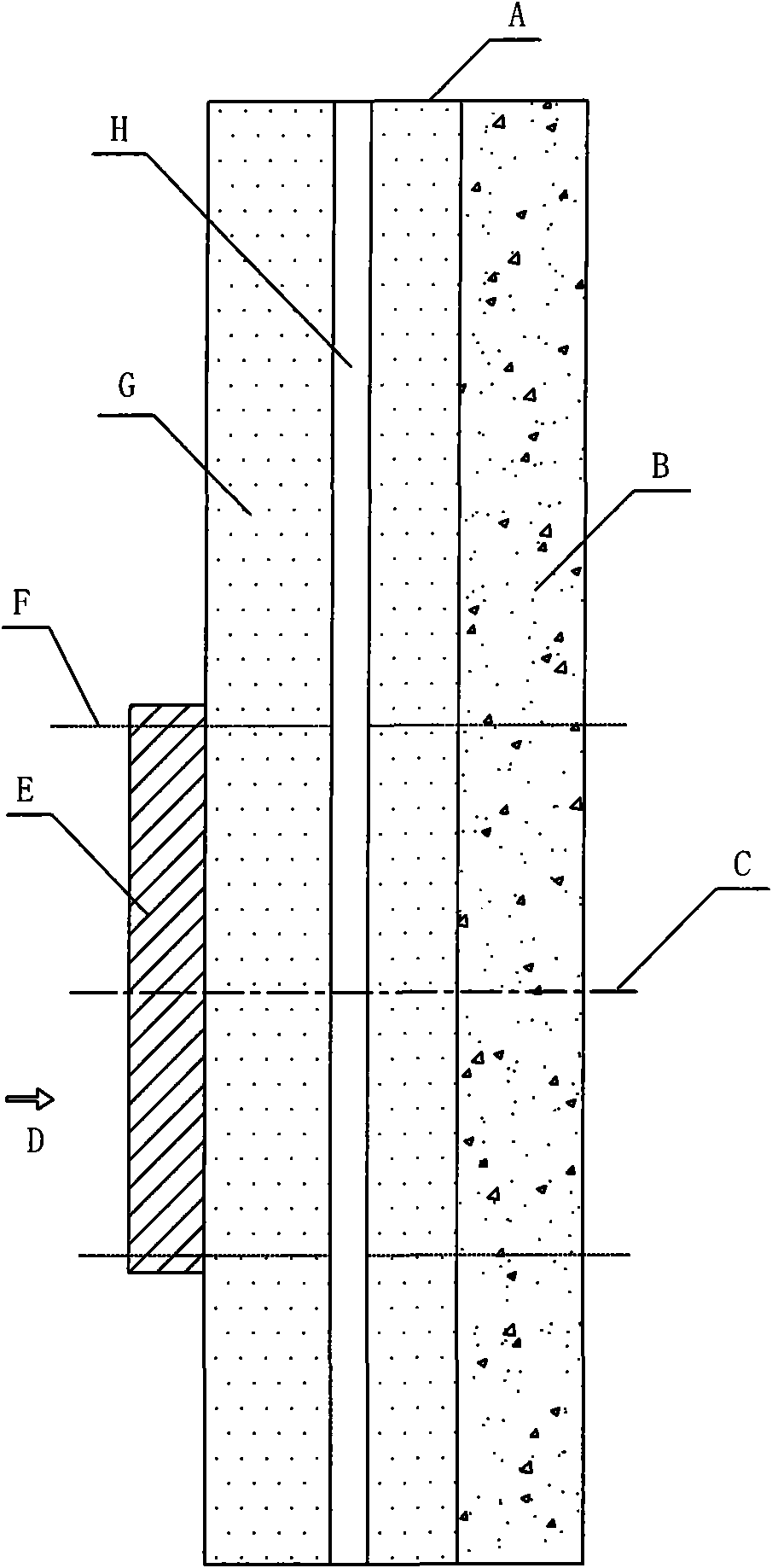

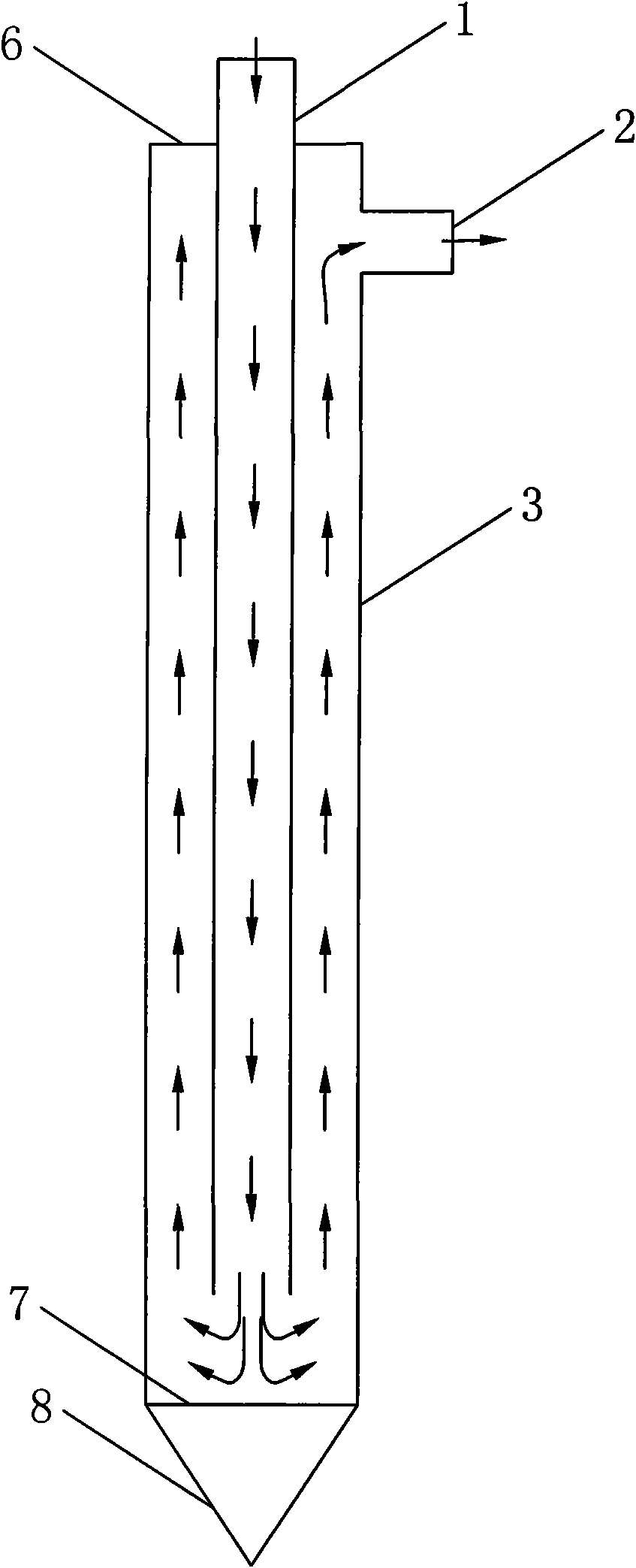

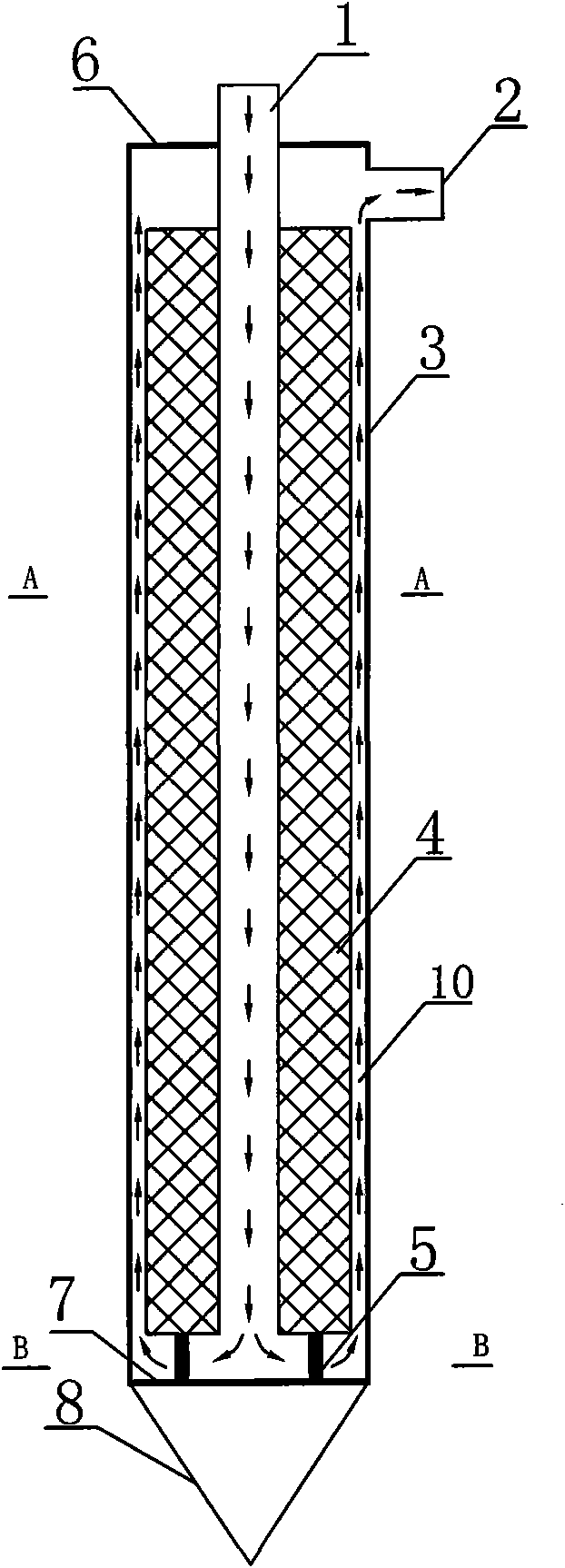

[0018] Below in conjunction with accompanying drawing, invention will be further described:

[0019] attached by image 3 As shown, the unplug-free freezer is mainly composed of a liquid supply pipe 1, a liquid return pipe 2, a freezing pipe 3, a thick-walled plastic pipe 4, a support member 5 and a bottom cone 8. Among them, the freezing tube 3 is the main body of the freezer, which is made of thin-walled aluminum or copper. Compared with the steel tube, the thin-walled aluminum or copper tube has the characteristics of low strength, toughness and strong low-temperature ductility. It will damage the cutter head; on the other hand, the heat transfer performance of aluminum or copper tube is better than that of steel tube, therefore, the unplug freezer using aluminum or copper tube as the freezing tube has good thermal conductivity, and the freezing effect will not be affected; The top of the tube 3 is provided with an upper sealing plate 6 of the same material, and the bottom...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com