Supporting structure for vehicle power source

A technology of vehicle power and support structure, applied in power plant, vehicle parts, jet propulsion and other directions, can solve the problems of power source roll/tilt, short distance, easy to feel by passengers, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] A preferred embodiment of the present invention will be described in detail below with reference to the accompanying drawings.

[0036] a. Support structure of vehicle power source

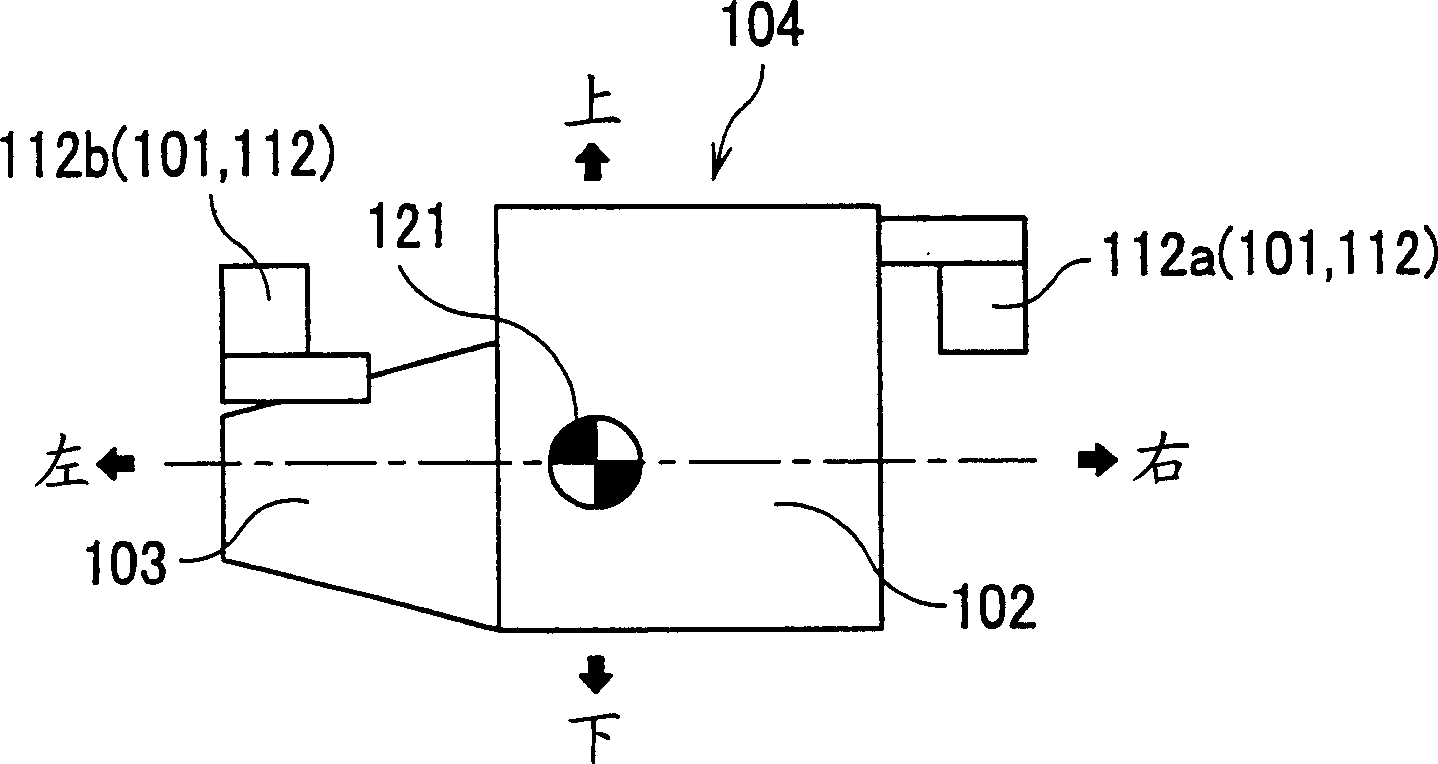

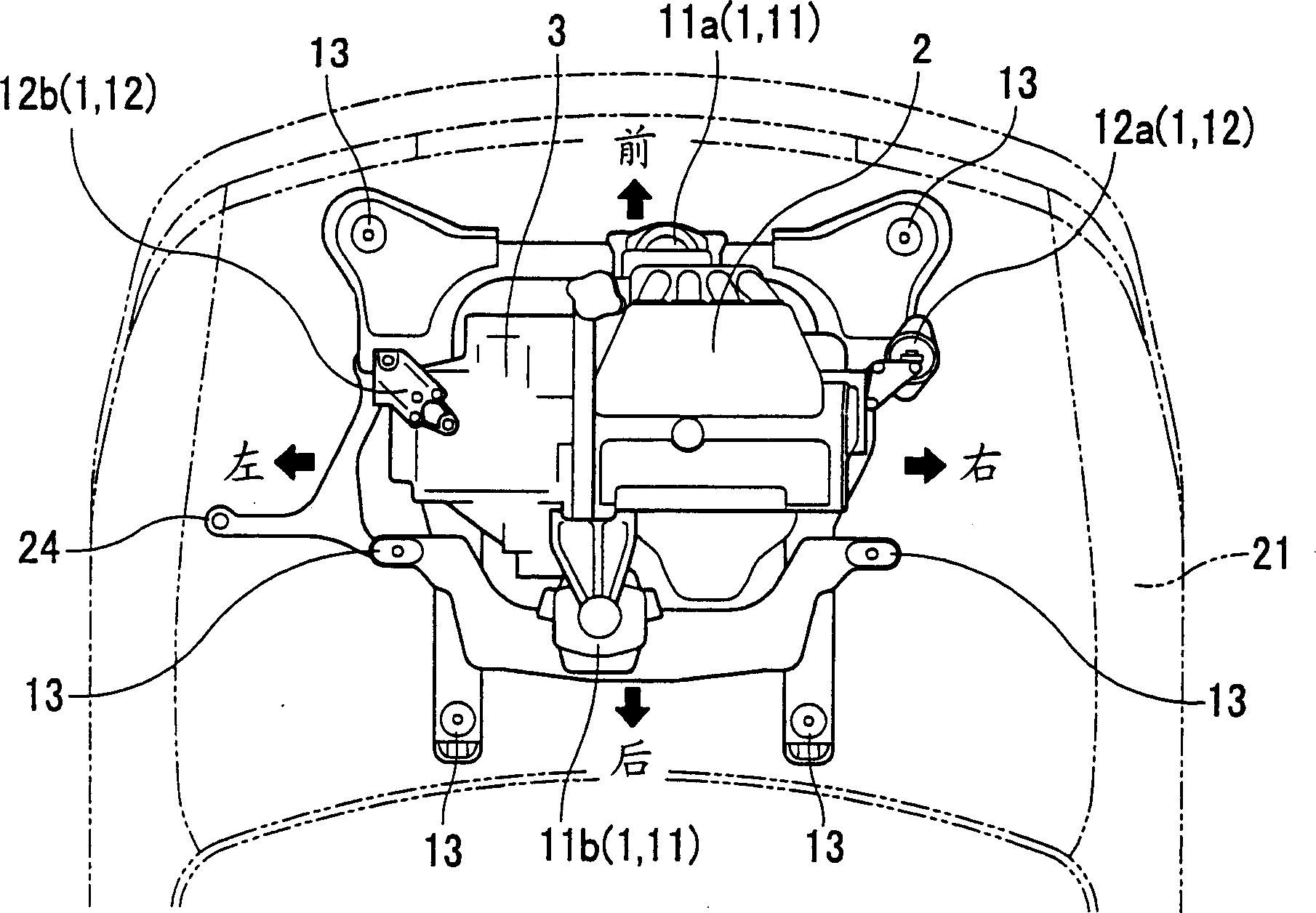

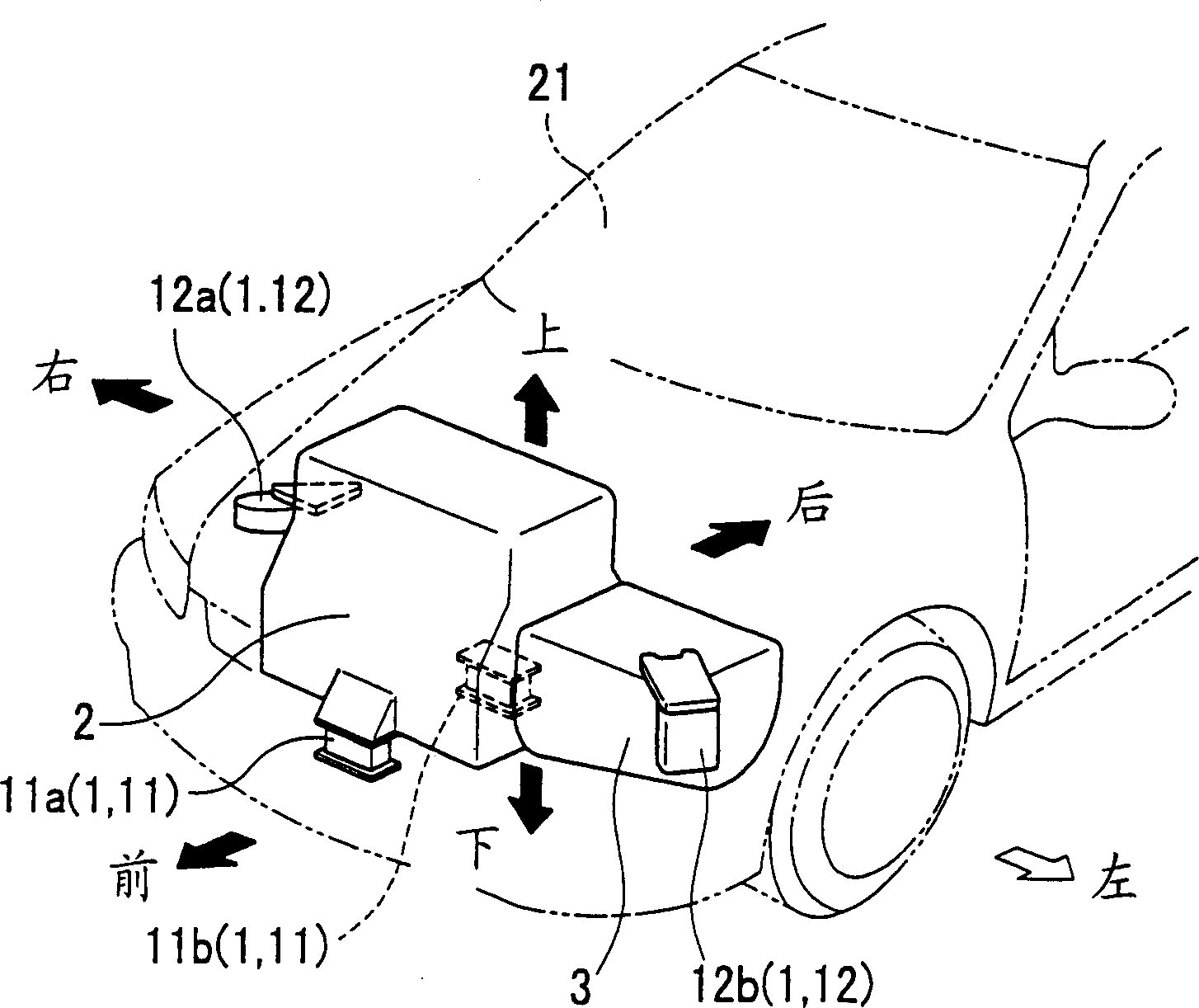

[0037] Figure 2A and 2B A plan view and a perspective view respectively show the overall structure of a support structure of an embodiment of the present invention. Figure 3A , 3B 3C and 3C show a plan view, a rear view and a side view, respectively, of a schematic structure of a support structure according to an embodiment of the present invention.

[0038] In the embodiment, the support structure is designed to support the engine 2 as the power source of the vehicle on the vehicle body 21 through a plurality of elastic mounting frame components 1 .

[0039] Here, the engine 2 is designed such that the transmission 3 is connected to one end of its crankshaft (not shown in the figure), and the crankshaft is arranged laterally relative to the vehicle body 21 .

[0040] Such a pluralit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com