Construction method for preventing vertical cracking between main structure and filled wall

A technology of the main structure and construction method, applied in the direction of walls, building components, building structures, etc., can solve the problems of repeatability of crack repair and poor comprehensive effect of crack control, achieve obvious economic and social benefits, reduce masonry The block loss rate and the effect of reducing cracks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] In order to further understand the invention content, characteristics and effects of the present invention, the following examples are given, and detailed descriptions are as follows in conjunction with the accompanying drawings:

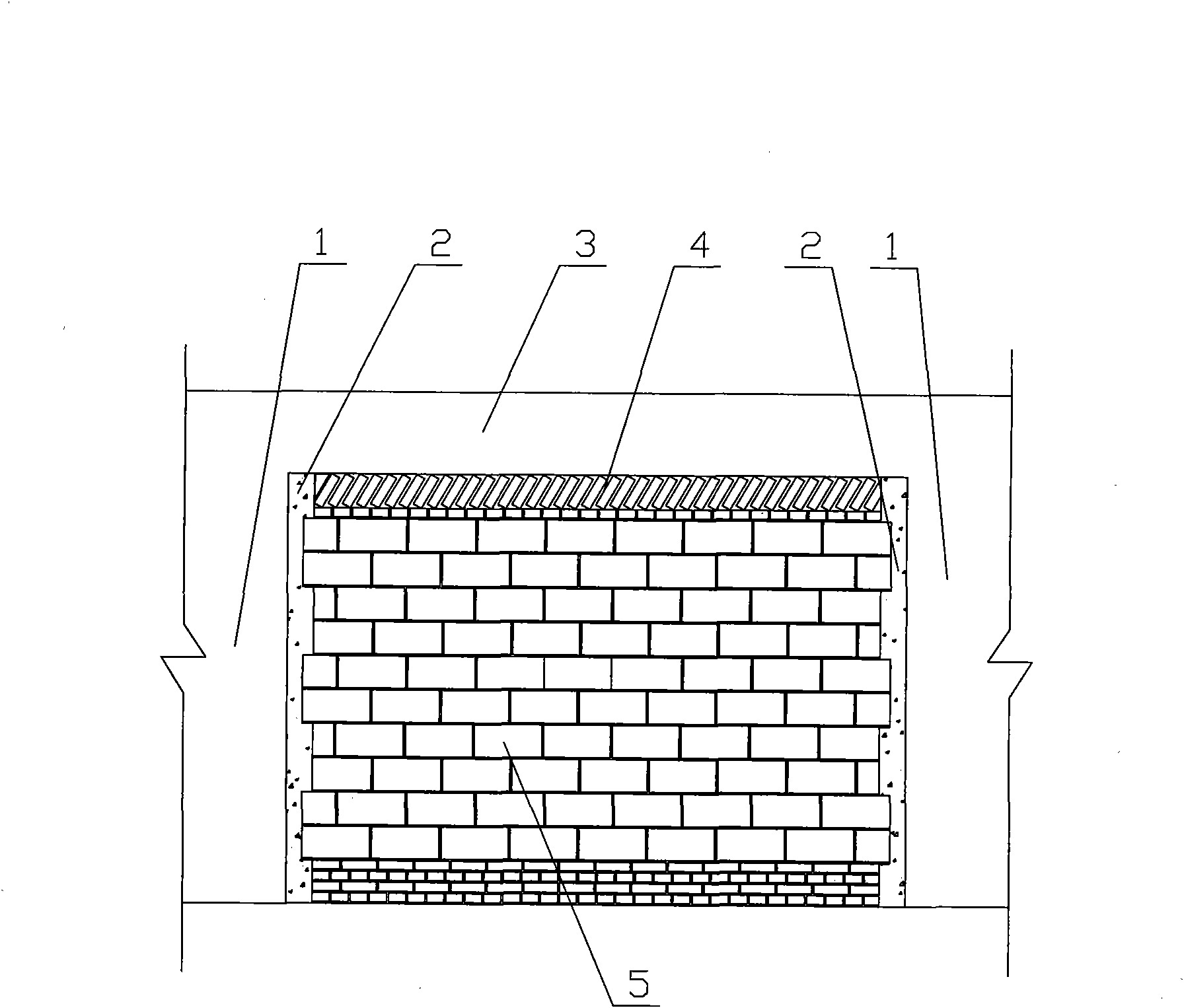

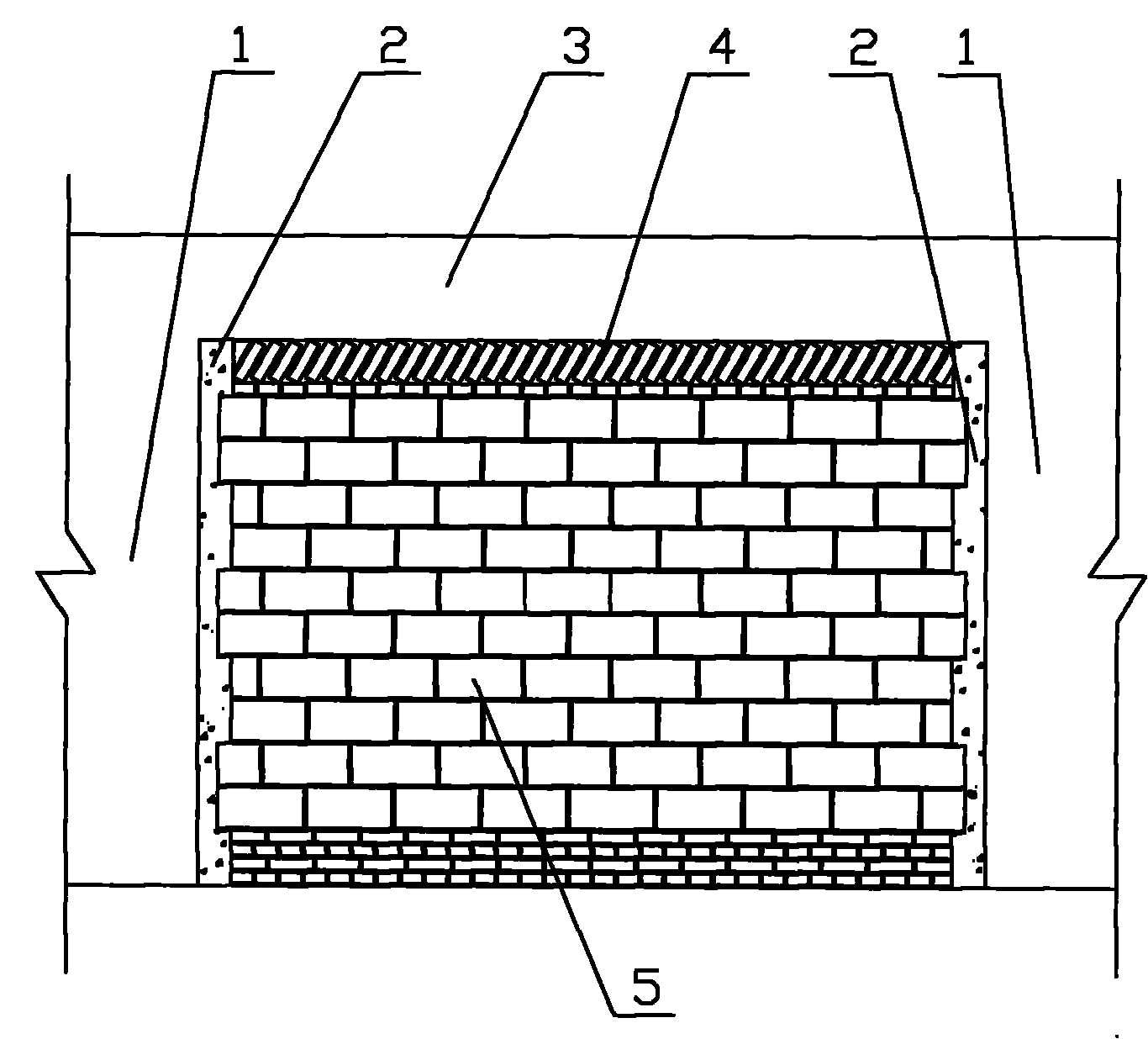

[0012] see figure 1 , a construction method to prevent vertical cracking between the main structure and the filling wall:

[0013] 1) After completing the construction of the main structure 1, before constructing the filling wall 5, reserve a space for the joint column between the side of the filling wall 5 and the main structure 1;

[0014] 2) Complete the construction of the filling wall 5; when constructing the filling wall 5, build the side surface connected with the main structure 1 into a mosaic, the upper part of the filling wall 5 is connected with the structural beam 3 through the inclined brick 4, and the filling wall The tie bars set in the body 5 should penetrate through the reserved space of the joint column and connect with the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com