Grouting sleeve for rebar connection

A technology of grouting sleeves and steel bars, which is applied to structural elements, building components, building reinforcements, etc., can solve problems such as inability to guarantee project quality, inaccurate positioning, and difficult axial control, so as to improve construction quality and axial positioning Accurate, easy-to-operate results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

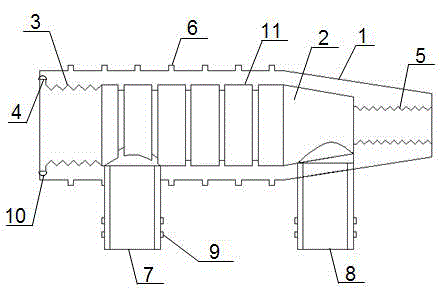

[0013] Accompanying drawing is a kind of specific embodiment of the present invention. This embodiment includes a grouting cylinder 1, the interior of the grouting cylinder 1 is a grouting cavity 2, one end of the grouting cylinder 1 is provided with a threaded button 3 inserted into the first steel bar, the threaded button 3 communicates with the cavity 2, and the end of the threaded button 3 There is a protruding notch 4, the other end of the grouting cylinder 1 is provided with a sleeve thread 5 connecting the second steel bar; the outer surface of the grouting cylinder 1 is provided with a shear ring 6, and the grouting cylinder 1 is close to the screw 3 One end is provided with a grouting port 7, and one end close to the sleeve thread 5 is provided with a grouting port 8, the outer surfaces of the grouting port 7 and the grouting...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Wall thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com