Steel wire net frame type composite interlayer wallboard internally installed with three layers of insulation boards and construction method of composite interlayer wallboard

A three-layer thermal insulation, steel wire mesh frame technology, applied in building components, buildings, building structures, etc., can solve the problems of increasing labor force, increasing the difficulty of assembling, increasing the weight of components, etc., to achieve the effect of enhancing the occlusal force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

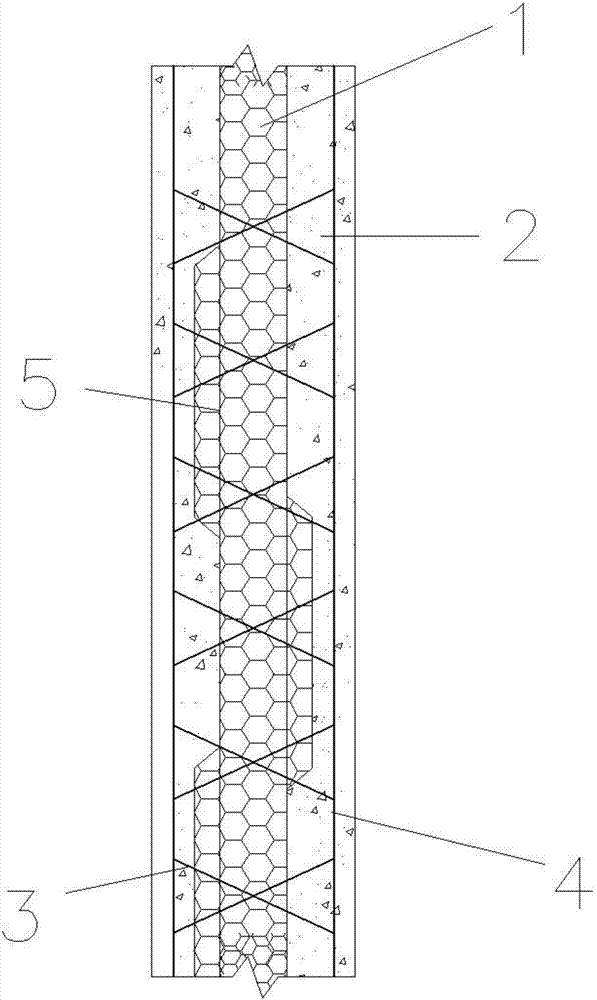

[0029] like figure 1 As shown, a steel wire frame composite sandwich wallboard with a built-in three-layer insulation board of the present invention includes two steel wire mesh sheets 4 parallel to each other and a plurality of steel wire mesh sheets 4 with a diameter of 3 mm for connecting the two steel wire mesh sheets 4. A steel wire grid frame composed of cold-drawn and obliquely inserted steel wires 3, a three-layer insulation board 1 sandwiched between two steel wire mesh sheets 4, and concrete layers 2 arranged on both sides of the insulation board 1. The cold-drawn obliquely inserted steel wires 3 are distributed in an "X" shape. The steel mesh sheet 4 is welded by vertical and horizontal intersecting steel wires with a horizontal interval and a longitudinal interval of 50 mm. The three-layer insulation board 1 includes a thicker main insulation board 1 in the middle, and thinner insulation boards 1 are respectively arranged at intervals on both sides; the thickness ...

Embodiment 2

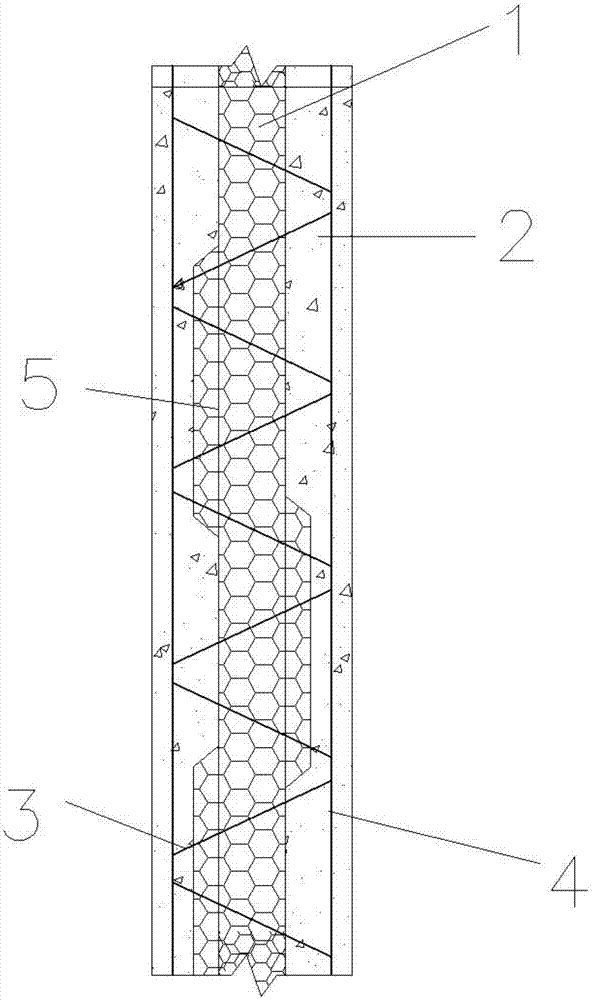

[0035] like figure 2 As shown, a steel wire grid composite sandwich wallboard with a built-in three-layer insulation board of the present invention has cold-drawn obliquely inserted steel wires 3 in a "eight"-shaped distribution, and other structural settings and construction methods are the same as in Example 1. No more details here.

[0036] The invention splices the three-layer insulation boards through the built-in steel wire grid, avoids the existence of cold bridges at the joints, improves the insulation performance, and reasonably splices the three-layer insulation boards to form a horse-toothed bridge, which enhances the contact between the insulation boards and the concrete The occlusal force of the surface increases the rigidity of the structure; the two sides of the insulation layer are concavo-convex and alternate, which is conducive to the on-site spraying and leveling of the concrete layer; by assembling and pouring together with the vertical restraint component...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com