Splicing-insertion type glass fiber reinforced plastic tray

A glass fiber and reinforced plastic technology, applied in the field of spliced glass fiber reinforced plastic pallets, can solve the problems of poor mechanical strength, low rigidity, rusted structure of iron nails, etc., to ensure the connection strength and overall performance, mold size. The effect of reducing requirements and reducing mold costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

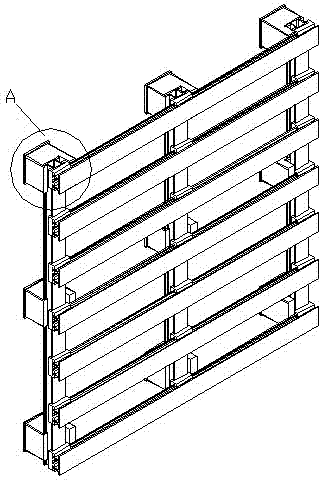

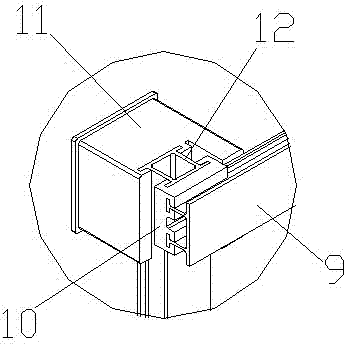

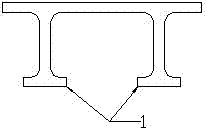

[0031] Embodiment 1: as Figures 1 to 8 As shown, the interlocking glass fiber reinforced plastic tray of this embodiment is composed of a panel 9 , a stand 11 and a beam 12 . The panel 9 is composed of a panel double T-shaped structure 1 and a connecting block 10, the lower part of the panel double T-shaped structure 1 is a double T-shaped structure, and the upper part is a plane. The double T-shaped slot structure 3 of the connecting block is arranged on the top of the connecting block 10, and the double T-shaped structure 1 of the panel is stuck in the double T-shaped slot structure 3 of the connecting block. A connection block T-shaped groove structure 2 is arranged on the top of the connection block 10 . The beam 12 is vertically arranged below the panel 9 , the top of the beam 12 is the upper beam 5 , and the lower part is the lower beam 13 , and the upper beam 5 and the lower beam 13 are connected by a beam support column 14 . The top 5 of the beam is just stuck in th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com