Construction method for subbase layer of natural graded pebble road surface

A natural gradation and construction method technology, applied to roads, roads, on-site coagulation pavements, etc., can solve the problems of high construction cost, small contact surface, poor bite force, stability and hardening, and achieve reduction Construction cost, effect of improving bite force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

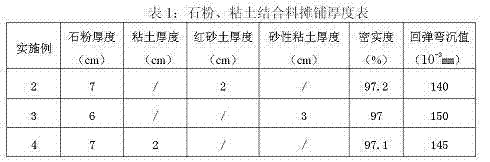

Examples

Embodiment 1

[0022] First, prepare the underlayment. After inspecting the subgrade in strict accordance with the design and specification standards, carry out measurement and lofting and divide the cloth grid. Restore the middle piles at 20m intervals for straight road sections and 10m intervals for curved road sections, and release the sidelines; according to the design thickness of the subbase of 30cm, the loose paving coefficient of 1.30 given by the laboratory, and the vehicle capacity of the material transporter, mark the paving capacity of each vehicle. Area range, and draw a grid line on the top surface of the subgrade with white ash.

[0023] The second step is to pave natural graded pebbles. According to the design thickness of 30cm and the loose paving coefficient of 1.30 given by the laboratory, the natural graded pebbles are paved with bulldozers, and the gradation of pebble particles meets the requirements of relevant specifications; Stabilize the pressure (static pressure) ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com