Steel wire net frame composite heat-insulation sandwich wall board node and construction method thereof

A steel wire mesh frame and composite thermal insulation technology, which is applied in the field of building energy conservation and thermal insulation, can solve the problems of difficulty in ensuring the occlusal force of the concrete layer connection, affecting the thermal insulation effect, and difficult to guarantee rigidity, achieving simple construction, solving cold bridges, and avoiding cold bridges. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention is further described below in conjunction with embodiment.

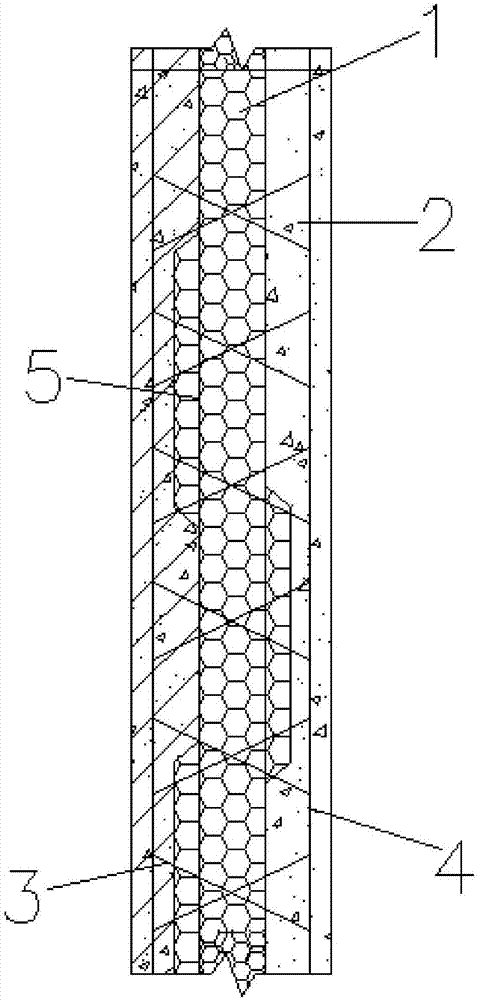

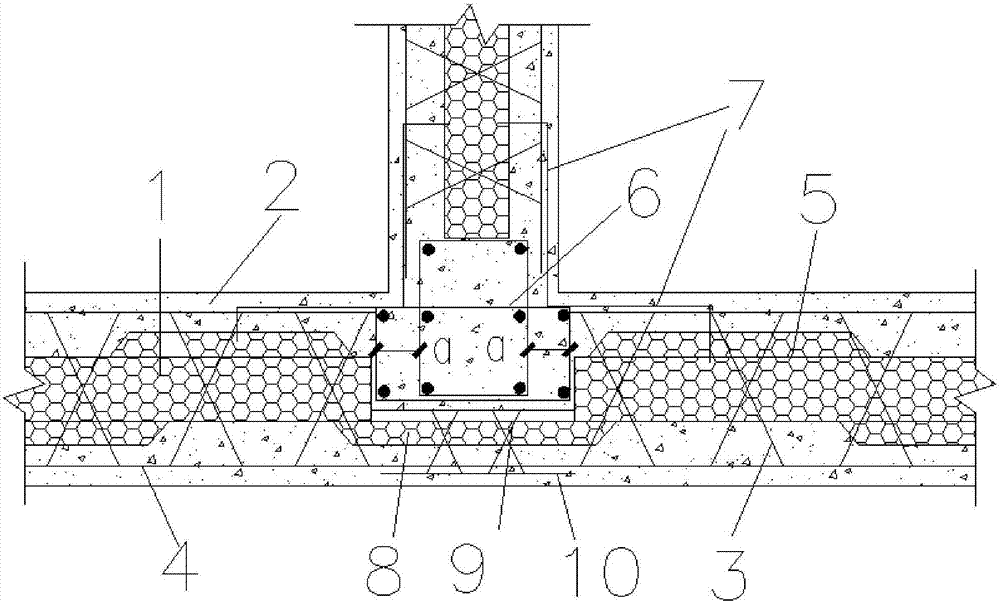

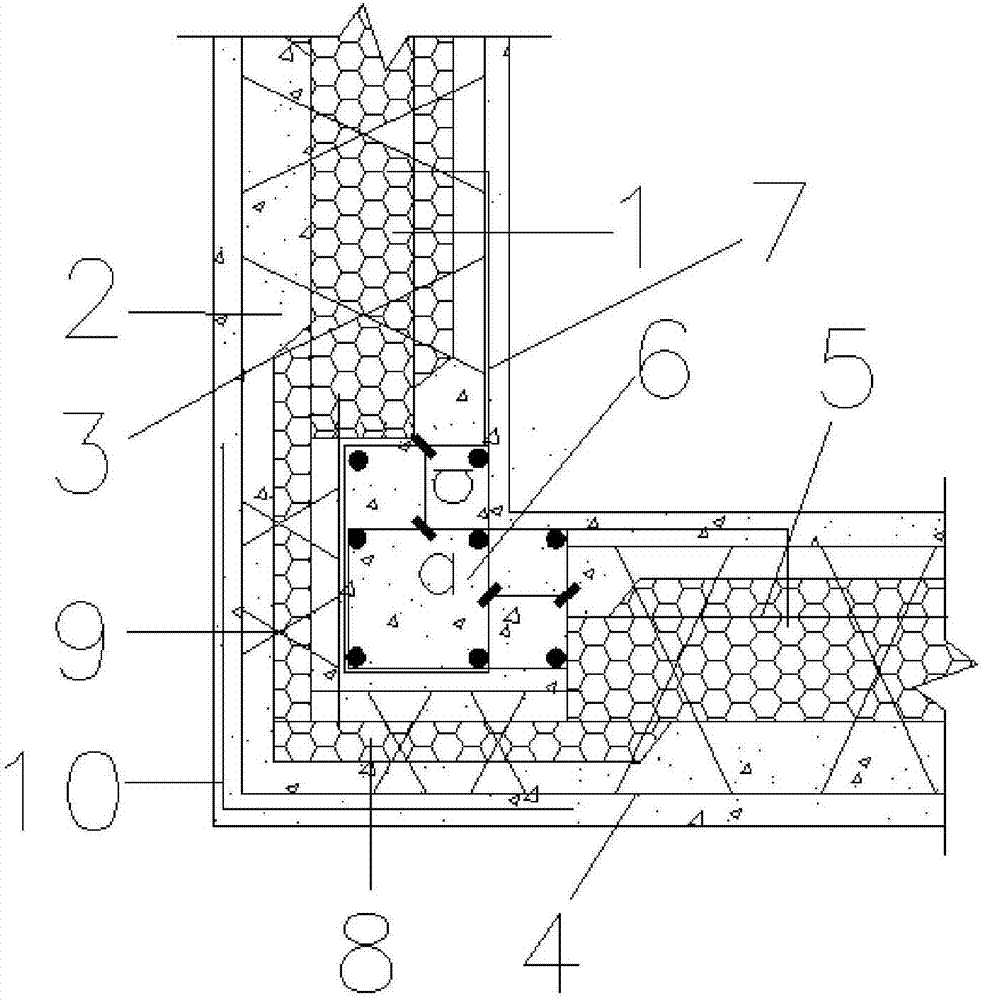

[0032] Such as Figure 1-4 As shown, a steel wire grid composite thermal insulation sandwich wall panel node of the present invention, the steel wire grid composite thermal insulation sandwich wall panel node is formed by connecting the steel wire grid composite thermal insulation sandwich wall panels to each other to form a "T" shape, "L ” or “Z” type joint structure, the connection of the wall panels is a column 6, such as figure 1 As shown, the steel wire frame composite thermal insulation sandwich wallboard includes a steel wire frame composed of two parallel steel wire mesh sheets 4 and a plurality of cold-drawn obliquely inserted steel wires 3 with a diameter of 3 mm for connecting the two steel wire mesh sheets 4 , a three-layer insulation board 1 sandwiched between two steel wire mesh sheets 4 and a concrete layer 2 arranged on both sides of the insulation board 1 . The steel me...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com