Pile-forming device and method for vortex pressing extruding and expanding concrete layering expanding pile

A technology of concrete and expanded diameter piles, which is applied in the direction of sheet pile walls, buildings, and foundation structure engineering, etc., can solve the problems of pile necking, insufficient pressure, and insufficient self-weight of equipment, etc., to achieve improved vertical and horizontal strength, good fluidity, The effect of simple construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

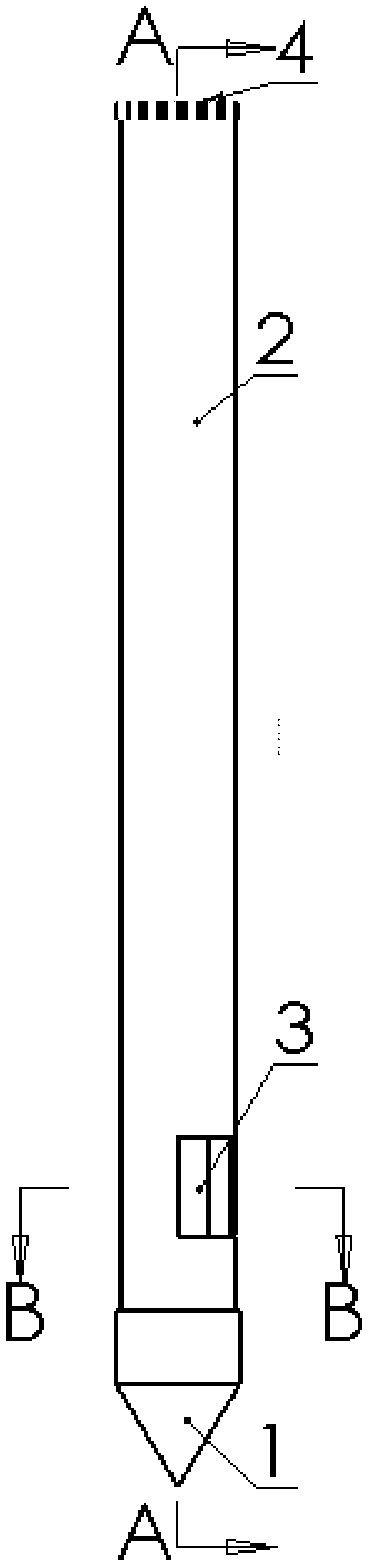

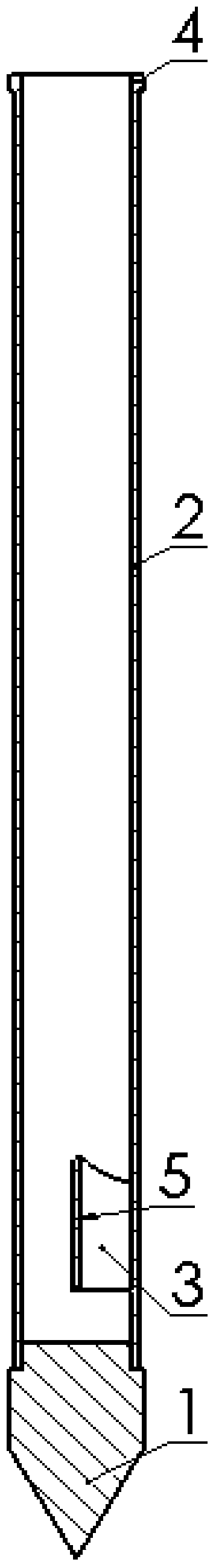

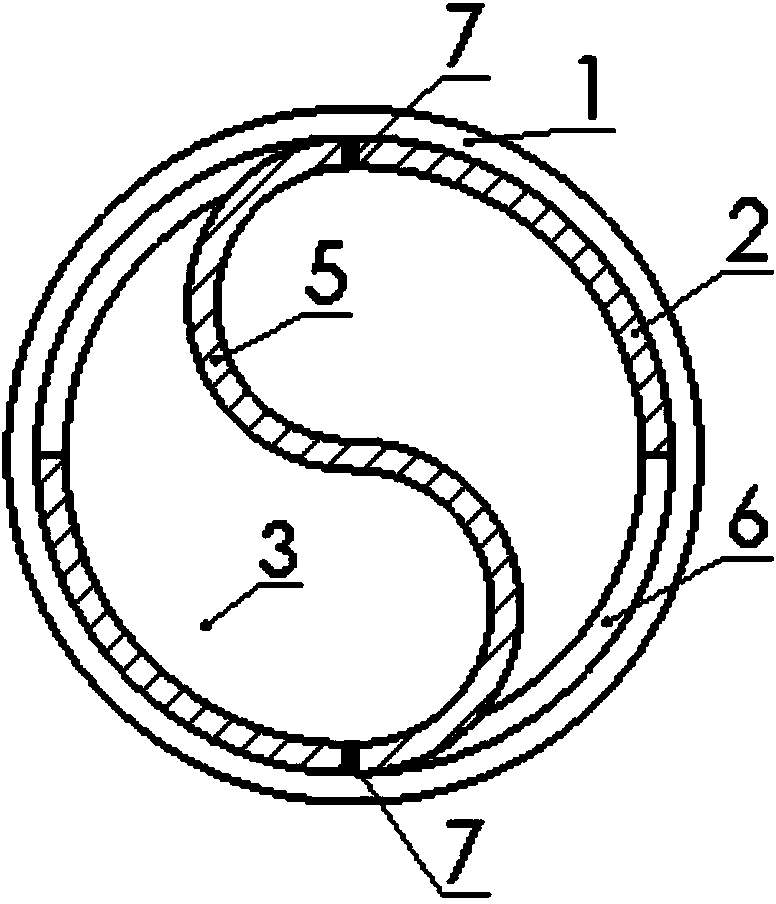

[0026] Such as figure 1 , figure 2 As shown, the pile-forming equipment of vortex squeezed and expanded concrete layered diameter-expanding piles includes: pile head 1, steel casing 2, rotating gear 4, radial vortex blade 5, axial vortex blade 8; pile head 1 It is arranged at the bottom of the steel sleeve, the rotating gear 4 is installed on the top of the steel sleeve 2, the radial scroll blade 5 is installed inside the opening of the steel sleeve, and the axial scroll blade 8 is located in the steel sleeve and installed on the diameter To the top of scroll blade 5; Wherein:

[0027] The pile head 1 is a prefabricated concrete structure, the upper part is a cylinder, the lower part is a cone, and the top of the cylinder forms a cylindrical boss.

[0028] The steel casing 2 is a metal round pipe, and the inner diameter of the steel casing 2 is slightly larger than the outer diameter of the cylindrical boss of the precast concrete pile head 1, so as to ensure that the top o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com