High-holding-power ship anchor and ship

An anchor and grip technology, applied in anchor points, ship parts, ship construction, etc., can solve the problems of poor balance and stability, unstable center of gravity, prone to overturning and tilting, etc., to ensure strength and balance, Improve the anchoring speed and strengthen the effect of the connecting structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

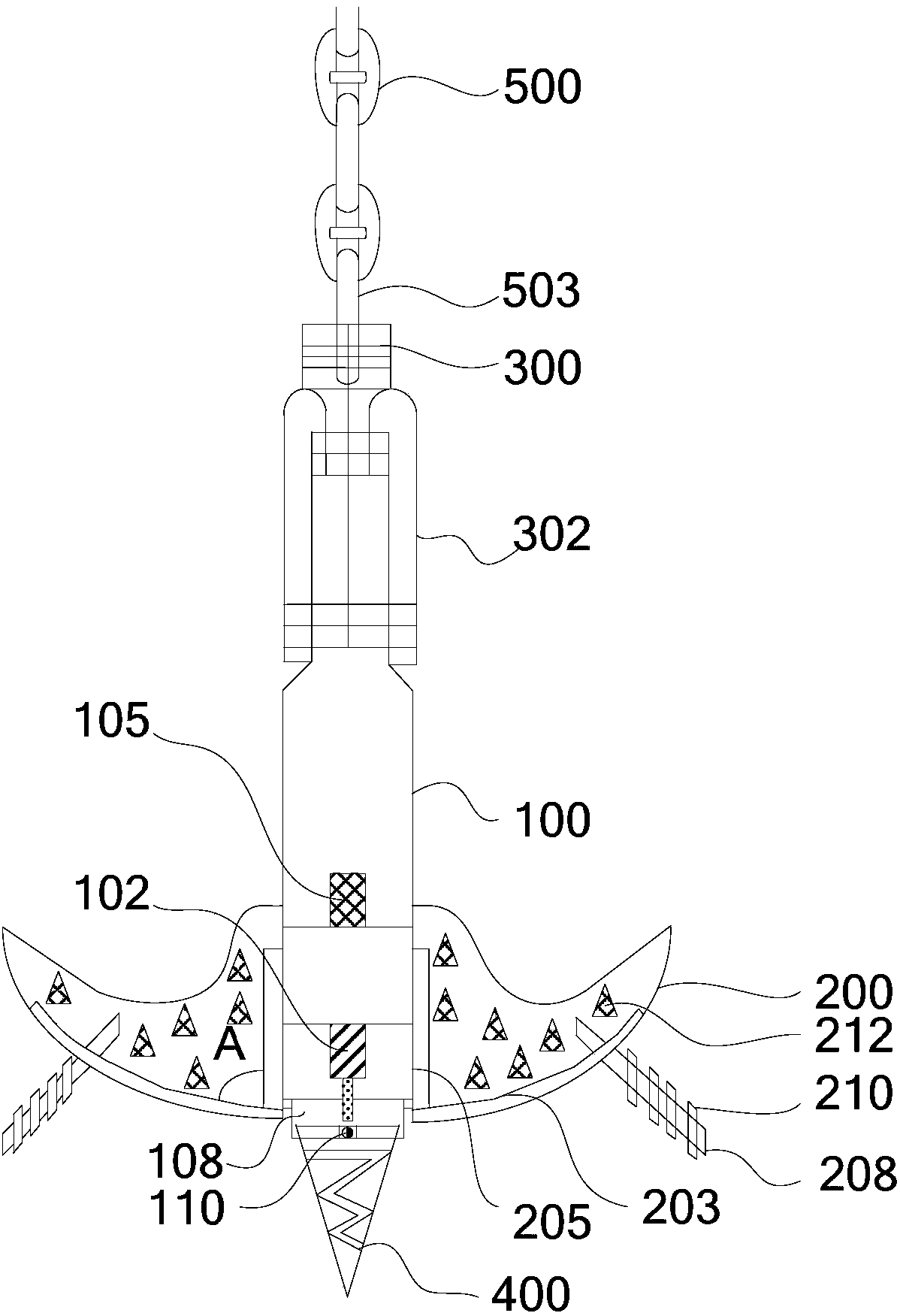

[0034] Such as figure 1 and Figure 4 As shown, the present invention provides a ship anchor with a large holding force, which includes: an anchor handle 100, a fluke 200 symmetrically arranged on the side edge of the bottom of the anchor handle 100, and a The rotating ring 300 , an anchor cone 400 rotatably provided at the bottom end of the anchor handle 100 , and the anchor chain 500 connected with the rotating ring 300 .

[0035] The end of the anchor chain 500 connected to the rotating ring 300 is an anchor end chain 503 ; the anchor end chain 503 is connected to the rotating ring 300 through bolts 505 . The swivel ring 300 is connected to the anchor handle 100 through an anchor shackle 302 .

[0036] see image 3 As shown, specifically, the end of the rotating ring 300 is cylindrical, and an external thread is provided on the end, and a nut 305 is installed on the anchor shackle 302, and the rotating ring 300 is screwed into the nut 305, and the tail of the rotating ri...

Embodiment 2

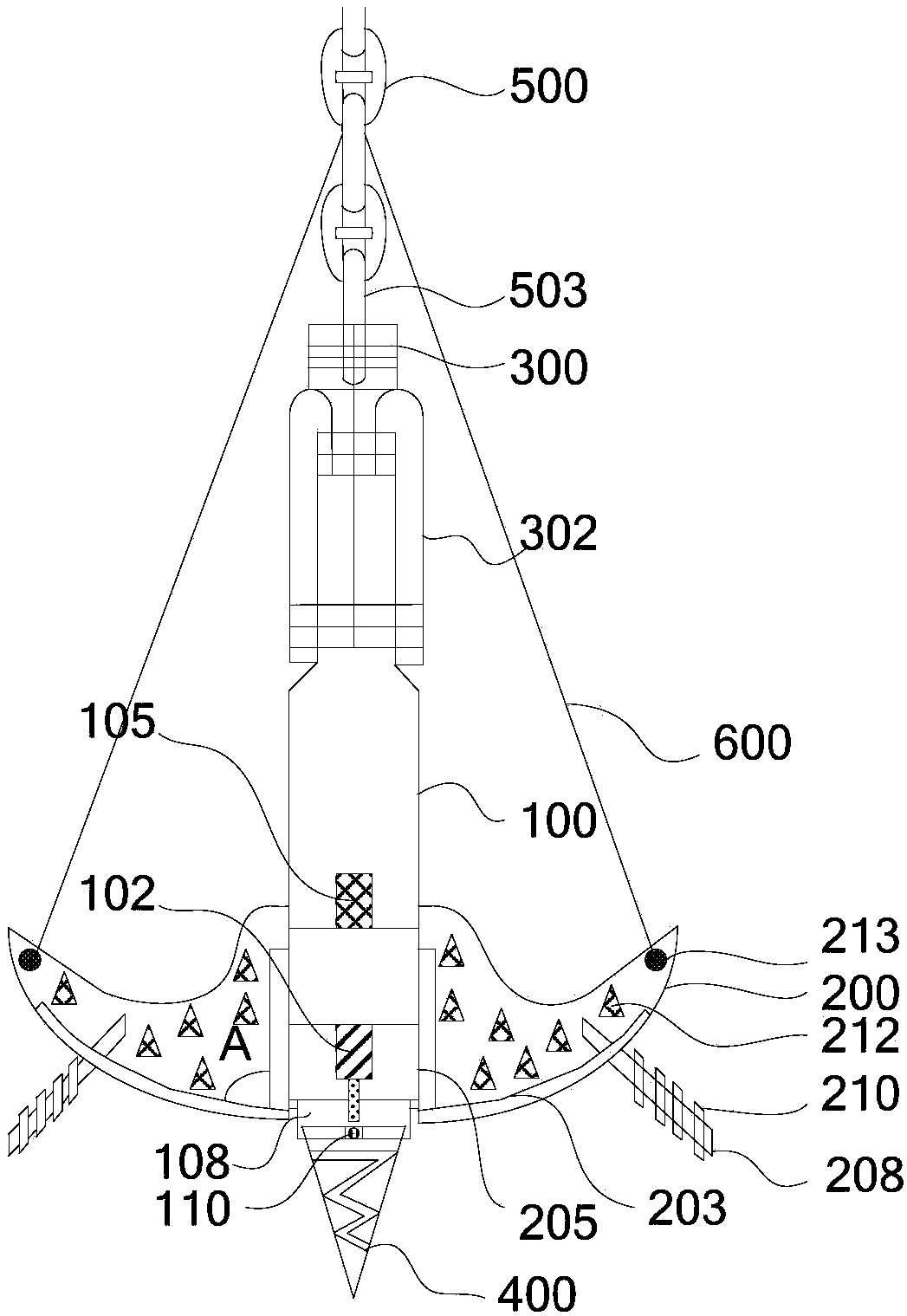

[0051] see figure 2 As shown, on the basis of Embodiment 1, the large-grasp anchor of this embodiment has roughly the same structure as that of Embodiment 1, the difference being that the fluke 200 of the large-grasp anchor of this embodiment A chain 600 connected to the anchor chain 500 is provided at the end angle of the chain, and the chain 600 can optionally adopt a steel rope. The chain 600 provided in this embodiment plays the role of assisting the anchoring, so that when the anchor is lifted, the whole ship's anchor can be exerted and pulled, so that the anchor can be lifted more quickly. Because the anchoring force of the ship anchor of the present invention on the seabed soil layer is strong, in the process of lifting the anchor, the anchoring force relying on the single point of the anchor chain 500 on the top of the anchor handle 100 may have relatively large resistance, so through the set chain 600, Realize multi-point force application and reduce anchor resistan...

Embodiment 3

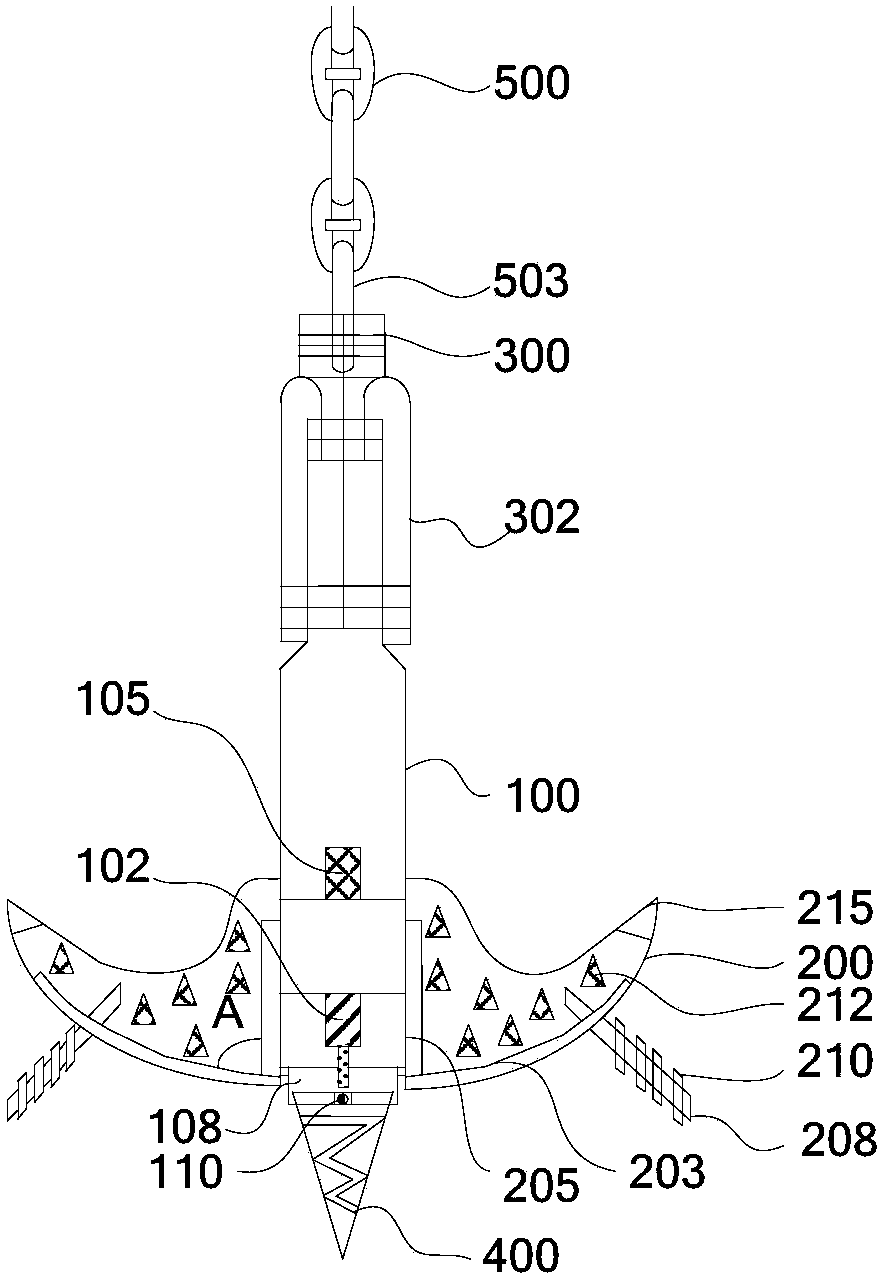

[0054] see image 3 As shown, on the basis of embodiment 1 or embodiment 2, the large grasping force anchor of the present embodiment has roughly the same structure as the large grasping force anchor of embodiment 1 or embodiment 2, the difference is that the large grasping force anchor of the present embodiment A detachable claw head 215 is provided at the corner of the fluke 200 of the gripping anchor which is not in contact with the anchor handle 100 . The claw head 215 is connected by, for example but not limited to, a screw-nut connection. The claw head 215 is designed as a detachable assembly method, which is convenient for timely replacement when the claw head 215 is damaged and deformed, because the anchor claw itself often contacts stones or slurry stones, and is easily deformed and damaged.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com