Coconut fiber and coconut geotextile composite reinforced expansive soil roadbed and construction method thereof

A coconut shell fiber and construction method technology, applied in the field of reinforced expansive soil subgrade structure, can solve the problems of unfavorable engineering construction, deformation growth, poor permeability, etc., and achieve the effect of simple and feasible construction technology, strong toughness and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

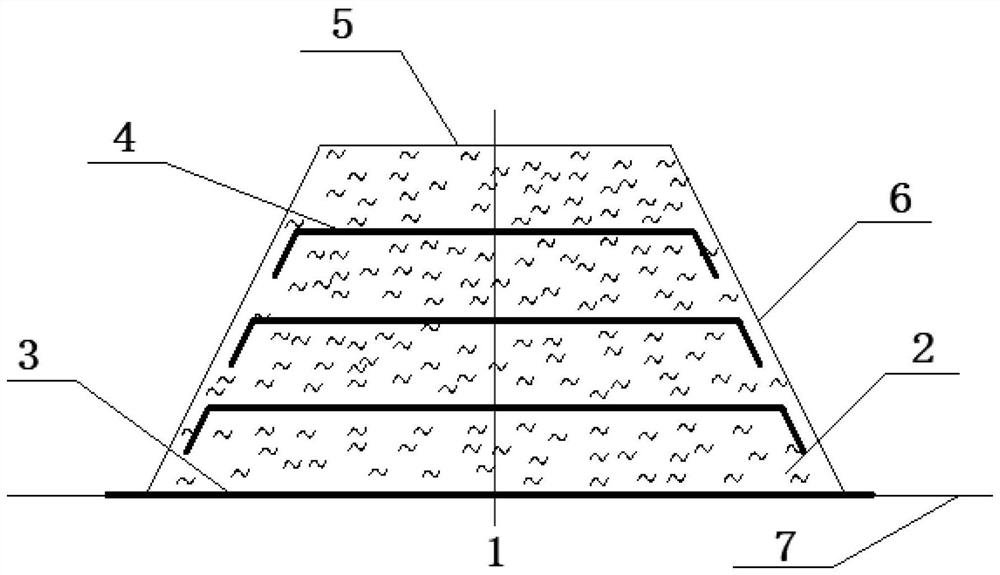

[0049] Embodiment 1: a kind of coir fiber and coir geotextile composite reinforced expansive soil roadbed, comprising: the subgrade, the subgrade laid on the top surface of the subgrade and the pavement layer laid on the top surface of the subgrade; wherein, the subgrade It includes subgrade base and multi-layer reinforced structural layer; the subgrade base is made of coir fiber and expansive soil mixed and compacted; the reinforced structural layer is laid in the subgrade base from bottom to top at intervals, and the topmost reinforced structural layer is located in the pavement layer. On the bottom surface, the reinforced structural layer is mainly composed of coconut shell geotextile.

[0050] Wherein, the length of the coir fiber is 30mm~120mm, preferably 60mm.

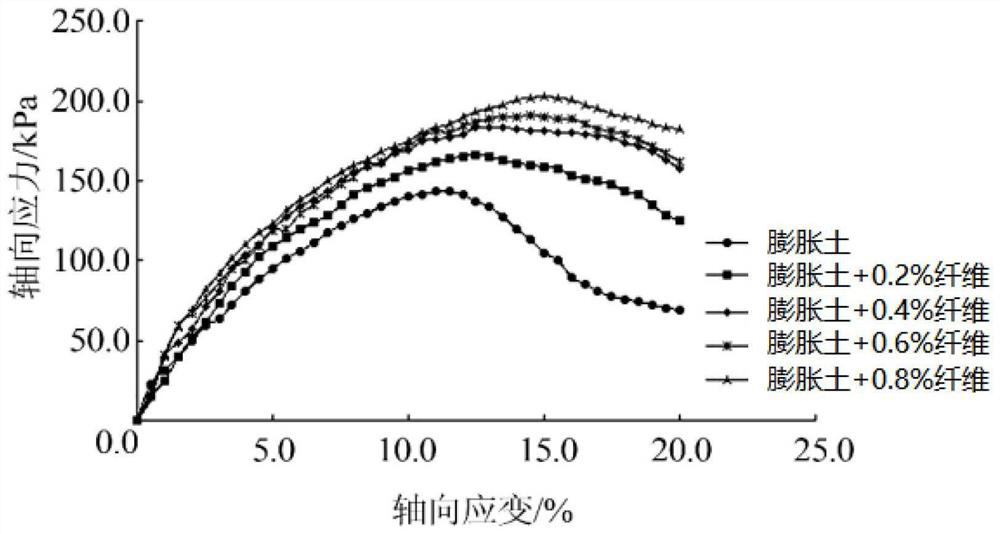

[0051] The optimum dosage of coconut husk fiber is determined by laboratory test, see step 3 of Example 2 for details; the mass ratio of coconut husk fiber to expansive soil is 0.8:100, and the distribution form ...

Embodiment 2

[0060] Embodiment 2: a kind of coir fiber and coir geotextile composite reinforced expansive soil roadbed construction method, such as figure 1 shown, including the following steps:

[0061] Step 1. Flatten and compact the construction site in a horizontal shape, remove the spikes and protrusions, and accurately release the slope line of the subgrade 6. In order to ensure the width of the subgrade 6, each side is widened by 0.5m, and the dried subgrade 7 is adjusted. After leveling, use a 25T vibratory roller to statically press twice, and then use a 50T vibratory roller for four times. The unevenness is manually leveled.

[0062] Step 1 can improve the bearing capacity of the foundation and prevent uneven settlement of the foundation.

[0063] Step 2. Lay a layer of coconut husk geotextile on the base of the roadbed 6 and the top surface of the foundation 7 as an isolation layer to isolate the soil of the foundation 7 from the filler 2, and lay it flat without wrinkles and t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com