Vacuum preloading and foundation heating combined foundation treatment system

A foundation treatment and vacuum technology, applied in soil protection, infrastructure engineering, construction, etc., can solve problems such as the reduction of drainage efficiency, and achieve the effect of reducing dynamic viscosity coefficient, reducing silting phenomenon, and improving soil strength.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

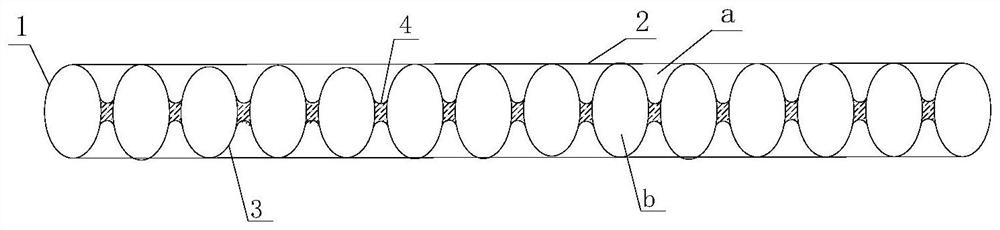

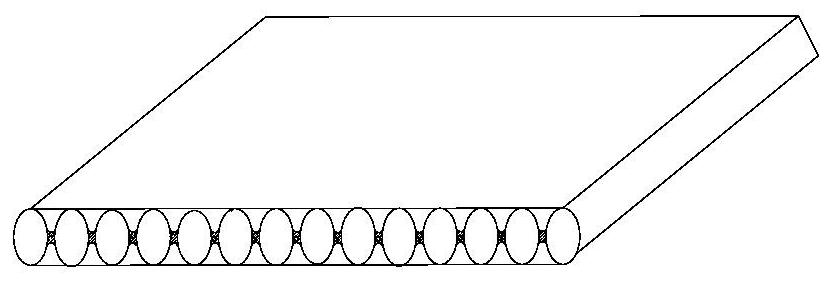

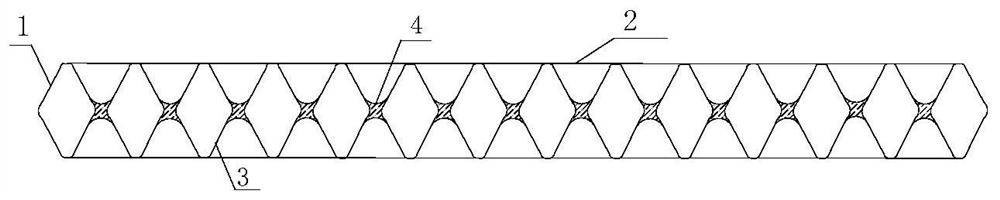

[0034] See attached Figure 1-6 , a new type of plastic drainage plate and its end joints, including material drainage plate and its end joints.

[0035] (1) Plastic drainage board part

[0036] The plastic drainage board includes a core plate 1 and a filter membrane 2 coated on the core plate. The width of the core plate 1 is preferably 50-200 mm, and the thickness is preferably 8-20 mm. The core plate 1 is composed of a plurality of relatively independent channel tubes 3 arranged side by side. The connection composition; the filter membrane 2 is coated on the core plate 1, and the space between the filter membrane and the outer wall of the channel pipe 3 of the core plate 1 forms a drainage channel a (during the drainage construction of the vacuum preloaded foundation, the water in the soft ground and the Air can pass through the filter membrane and enter the drainage channel), and the inner channel of the channel pipe 3 itself forms the inner channel b, so that the plastic...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com