Viscosity reducer for heavy oil and its application and method for viscosity reduction of heavy oil

A technology of viscosity reducer and heavy oil, which is applied in chemical instruments and methods, earth drilling and drilling compositions, etc. It can solve the problems of difficult control of polymerization degree, complicated polymer operation, adverse environmental impact, etc., and achieve cost reduction Inexpensive, easy to prepare, cheap effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

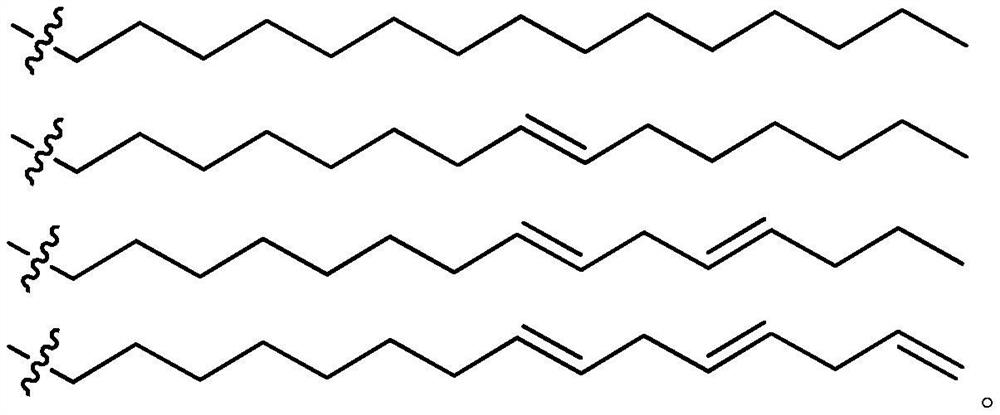

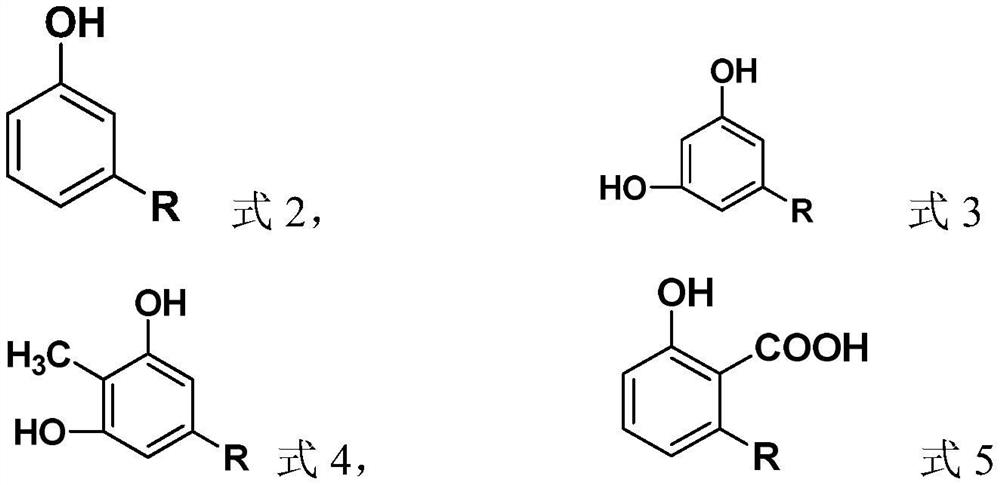

Method used

Image

Examples

Embodiment 1

[0062] This example is used to illustrate the heavy oil viscosity reducer and the heavy oil viscosity reducer method of the present invention.

[0063] (1) Preparation of heavy oil viscosity reducer

[0064] At 40°C, add 0.5g of perfluorooctanesulfonyl fluoride to 10g of cardanol and stir for 30 minutes to dissolve it, then add 0.5g of TX-4 to it, and continue stirring for 2 minutes to obtain thick oil viscosity reducer A1 .

[0065] (2) Thick oil viscosity reduction

[0066] Add 0.6g of thick oil viscosity reducer A1 to 20g of thick oil-I, then stir and dissolve at 200°C for 4 hours to obtain a mixed oil.

[0067] The dynamic viscosity of the mixed oil at 50°C and the stability results after aging for 10 days at 190°C are shown in Table 1.

Embodiment 2

[0069] This example is used to illustrate the heavy oil viscosity reducer and the heavy oil viscosity reducer method of the present invention.

[0070] (1) Preparation of heavy oil viscosity reducer

[0071] At 20°C, 0.1 g of perfluorooctanoic acid was added to 10 g of cashew nut shell oil and stirred for 10 minutes to dissolve it, then 0.1 g of TX-7 was added thereto, and the stirring was continued for 5 minutes to obtain thick oil viscosity reducer A2.

[0072] (2) Thick oil viscosity reduction

[0073] Add 0.1 g of heavy oil viscosity reducer A2 to 20 g of heavy oil-II, then stir and dissolve at 120°C for 4 hours to obtain a mixed oil.

[0074] The dynamic viscosity of the mixed oil at 50°C and the stability results after aging for 10 days at 190°C are shown in Table 1.

Embodiment 3

[0076] This example is used to illustrate the heavy oil viscosity reducer and the heavy oil viscosity reducer method of the present invention.

[0077] (1) Preparation of heavy oil viscosity reducer

[0078] At 30°C, add 1.0g of methyl perfluorooctanoate to the mixture of 5g of cashew nut shell liquid and 5g of cardanol and stir for 30 minutes to dissolve it, then add 1.0g of TX-4 to it, and continue stirring for 2 minutes to obtain a thick Oil viscosity reducer A3.

[0079] (2) Thick oil viscosity reduction

[0080] Add 1 g of thick oil viscosity reducer A3 to 20 g of thick oil-III, and stir and dissolve at 200°C for 4 hours to obtain a mixed oil.

[0081] The dynamic viscosity of the mixed oil at 50°C and the stability results after aging for 10 days at 190°C are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com