A kind of purification method of anthracite-based microcrystalline graphite for preparing negative electrode material of lithium ion battery

A lithium-ion battery, microcrystalline graphite technology, applied in battery electrodes, negative electrodes, secondary batteries, etc., can solve the problems of expensive equipment, low graphite purity, poor operation controllability, etc., to improve application potential and improve purification. Effect, effect of improving electrical performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

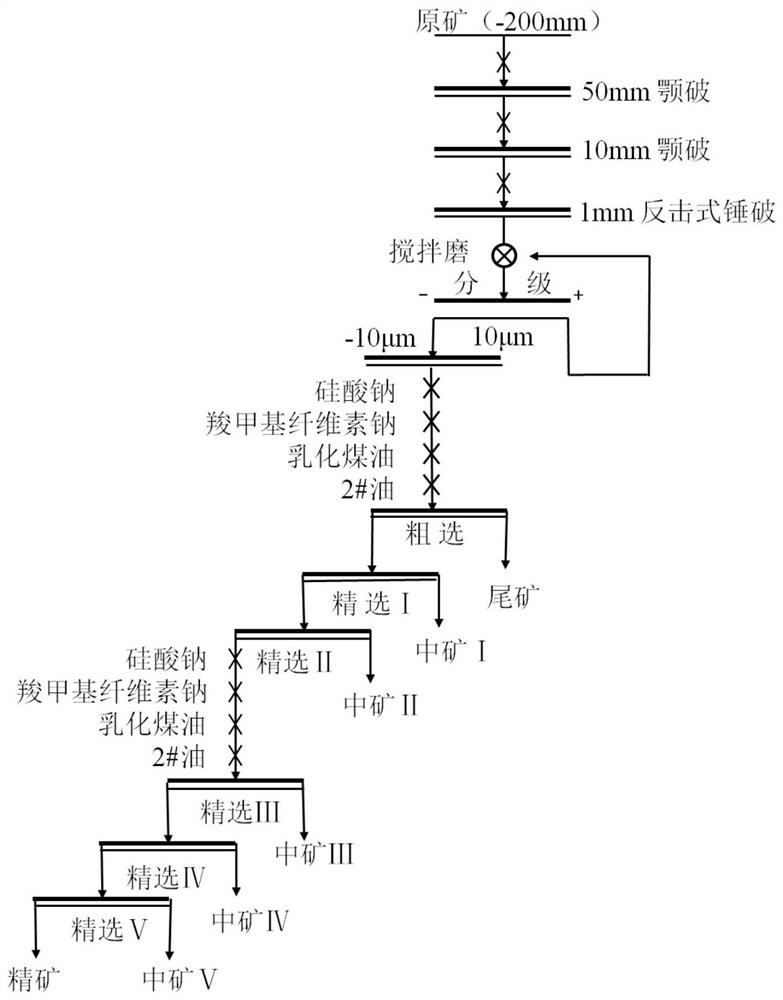

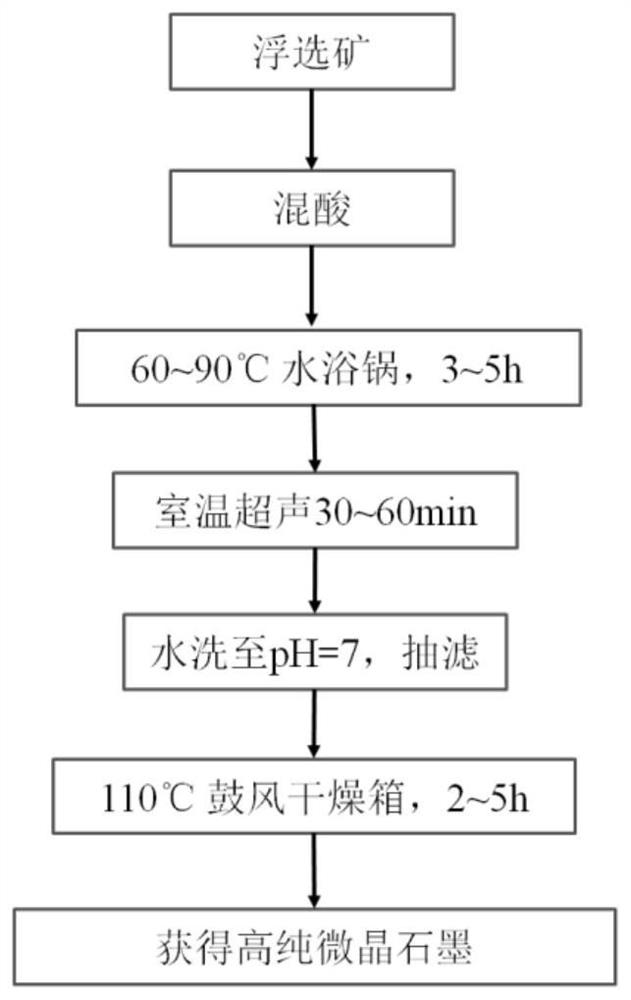

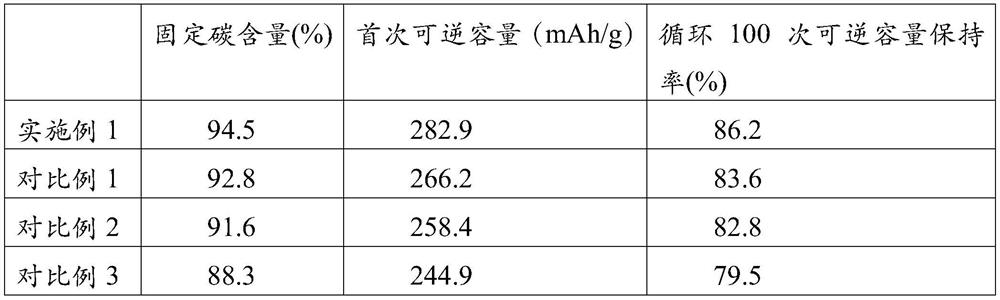

Embodiment 1

[0018] Example 1: Using natural anthracite-based microcrystalline graphite as raw material, it is crushed by 50mm and 10mm jaw crushers in turn, and then hammered by a 1mm impact hammer crusher, and then the particle size is less than 10 μm by horizontal stirring mill-dry method. The flotation feeding material; in the flotation cell, the flotation feeding material is subjected to a rough selection and five times of beneficiation, and the slurry concentration is controlled to be 20%, and the inhibitor sodium silicate 400g / t, carboxymethyl cellulose Sodium 200g / t, stirred for 3min, emulsifier MOA-3B and kerosene were mixed at a mass ratio of 1:9, in a high-speed mixer, mixed at a high speed of 800r / min for 3min, as a collector, the amount of collector added was 1000g / t, stir for 1min, then add foaming agent 2# oil 250g / t, stir for 1min, inflate at an airflow rate of 200L / h, scrape and bubble for 5min, collect the concentrate, and conduct 5 times of beneficiation in turn, and in ...

Embodiment 2

[0025] Example 2: Using natural anthracite-based microcrystalline graphite as raw material, it is crushed by 50mm and 10mm jaw crushers in turn, and then hammered by a 1mm impact hammer crusher, and then the particle size is less than 10 μm by horizontal stirring mill-dry method The flotation feeding material; in the flotation cell, the flotation feeding material is subjected to a rough selection and five times of beneficiation, and the slurry concentration is controlled to be 20%. Sodium 300g / t, stirred for 5min, emulsifier MOA-3B and kerosene were mixed at a mass ratio of 2:8, in a high-speed mixer, mixed at a high speed of 1000r / min for 5min, as a collector, the amount of collector added was 3000g / t, stir for 1min, then add foaming agent 2# oil 200g / t, stir for 1min, inflate at an air velocity of 250L / h, scrape and bubble for 5min, collect the concentrate, and carry out 5 times of beneficiation in turn, and in the 3rd beneficiation Add inhibitor sodium silicate 200g / t, sod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com