Thick oil viscosity reducer, preparation method thereof and thick oil viscosity reduction method

A technology of viscosity reducer and viscous oil, which is applied in chemical instruments and methods, earthwork drilling, drilling composition, etc., can solve the problems of complex operation in polymer synthesis process, difficult control of polymerization degree, influence of viscosity reduction effect, etc. , to achieve the effect of simple preparation, environmental protection, low cost and low price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0025] According to the second aspect of the present invention, the present invention provides a kind of preparation method of heavy oil viscosity reducer, comprising: (1) preparing biological phenol-aldehyde oligomer; (2) combining biological phenol-aldehyde oligomer with permeate agent mix.

[0026] The preparation method of the biophenol-aldehyde oligomer comprises: reacting the biophenol compound and the aldehyde in the presence of a catalyst, the mass ratio of the biophenol to the aldehyde is 10-30:1, preferably 12 ~20:1.

[0027] The biophenol is cardanol and / or cashew nut shell liquid. The aldehydes can be formaldehyde or paraformaldehyde.

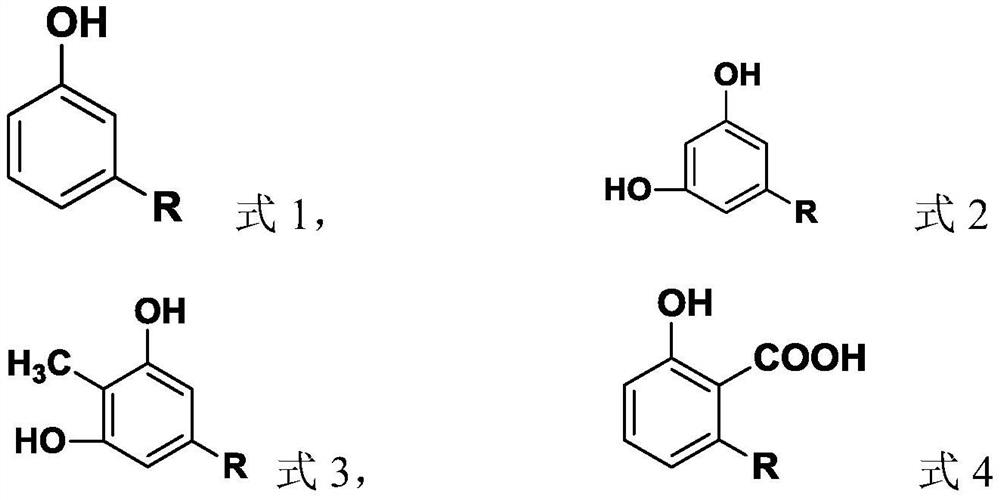

[0028] Those skilled in the art should understand that the cardanol is a mixture of phenol derivatives, mainly including monohydric phenol shown in formula 1 and dihydric phenol shown in formula 2;

[0029]

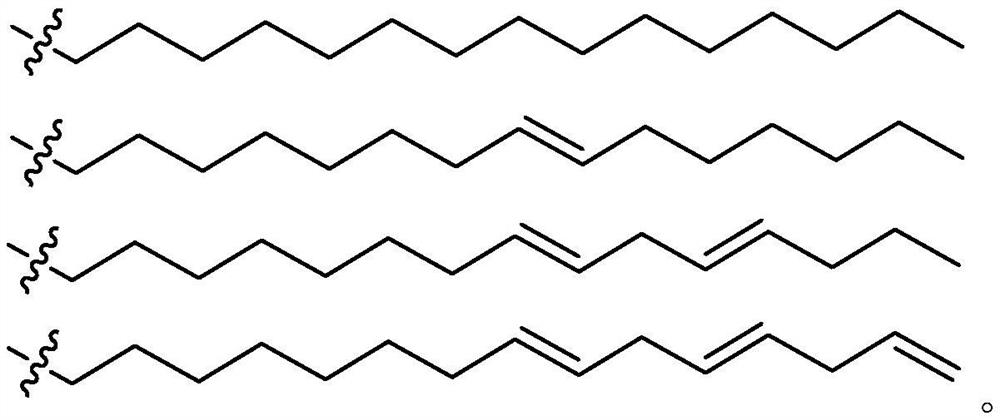

[0030] In formula 1 and formula 2, the general formula of R is C 15 h 25~31 , and R is a saturated straight-chain alk...

Embodiment 1

[0064] This example is used to illustrate the heavy oil viscosity reducer and the heavy oil viscosity reducer method of the present invention.

[0065] (1) Preparation of biophenol-aldehyde oligomers

[0066] Add 60 g of cardanol and 13.7 g of 36% formaldehyde solution in the three-necked flask, then add 1.47 g of p-toluenesulfonic acid and 75 g of xylene, and install a stirrer, reflux condenser, water separator and thermometer on the three-necked flask respectively. Under the condition of 200r / min, the temperature was raised to 90°C for 2 hours, and then the temperature was raised to 140°C for 2 hours to obtain the biophenol-aldehyde oligomer P1.

[0067] (2) Preparation of heavy oil viscosity reducer

[0068] At 40°C, 0.5 g of perfluorooctane sulfonyl fluoride was added to 10 g of the biophenol-aldehyde oligomer P1 prepared in step (1), and stirred for 30 minutes to dissolve it to obtain thick oil viscosity reducer A1.

[0069] (3) Thick oil viscosity reduction

[0070] A...

Embodiment 2

[0073] This example is used to illustrate the heavy oil viscosity reducer and the heavy oil viscosity reducer method of the present invention.

[0074] (1) Preparation of biophenol-aldehyde oligomers

[0075] Add 60 g of cardanol and 4.0 g of paraformaldehyde in a three-necked flask, then add 1.30 g of p-toluenesulfonic acid and 32 g of xylene. Biophenol-aldehyde oligomer P2 was prepared under the same reaction conditions as in Example 1.

[0076] (2) Preparation of heavy oil viscosity reducer

[0077] At 20°C, 0.1 g of perfluorooctanoic acid was added to 10 g of the biophenol-aldehyde oligomer P2 prepared in step (1), and stirred for 10 minutes to dissolve it to obtain thick oil viscosity reducer A2.

[0078] (3) Thick oil viscosity reduction

[0079] Add 0.05 g of thick oil viscosity reducer A2 to 20 g of thick oil-2, and stir and dissolve at 120°C for 4 hours to obtain a mixed oil.

[0080] The dynamic viscosity of the mixed oil at 50°C and the stability results after a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com