Collision device for purifying oil fume

A collision device and oil fume technology, which is applied in the direction of oil fume removal, household heating, lighting and heating equipment, etc., can solve the problems of increasing the risk of fire in the flue, the exhaust smoke cannot reach the emission concentration, and the oil fume purification efficiency is poor. Less oil leakage, less pressure drop and less maintenance cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

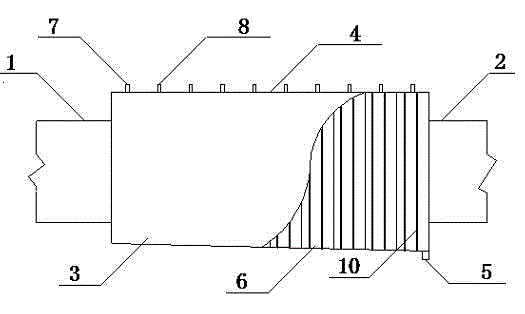

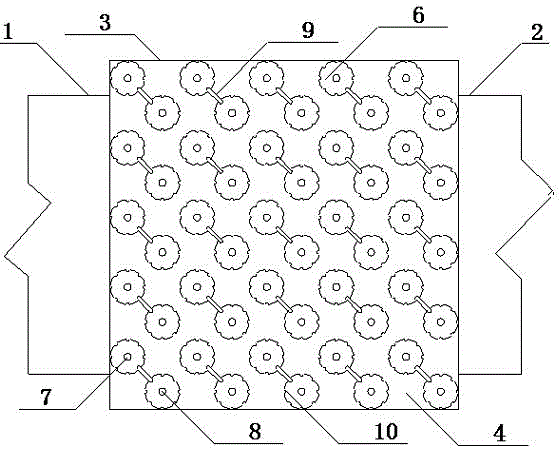

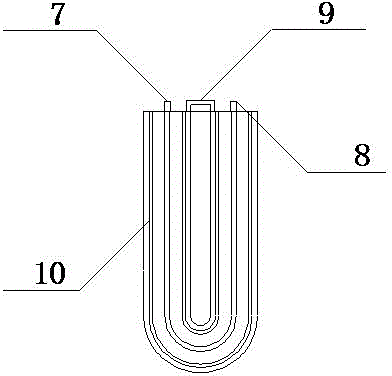

[0024] In the case of high oil fume concentration, the oil fume purifying collision device cooperates with other components to purify the oil fume generated during the production process of large and medium-sized catering units.

[0025] Such as Figure 4As shown, the cooker 11 produces oily fume and is captured by the gas collecting hood 12. The inner top of the gas collecting hood 12 is arc-shaped, and a filter screen 13 is housed on it, and an oil collecting groove is provided at the bottom. The flue gas is captured by the gas collecting hood 12 and enters the circular flue 14 tangentially. The bottom of the circular flue 14 is provided with an oil discharge hole 15. The circular flue 14 and the indoor rectangular oil fume pipe 17 are provided with a fire damper 16. Shape flue 14 is tangentially connected with indoor rectangular oil fume pipe 17, indoor rectangular oil fume pipe 17 is connected with rectangular oil fume pipe purification unit 3, rectangular oil fume pipe pu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com