Special-shaped drainage anti-skidding pile and construction method thereof

An anti-slide pile and special-shaped technology, which is applied in the construction of special-shaped drainage anti-slide piles, and in the field of special-shaped drainage anti-slide piles. Discharge and other problems, to achieve the effect of reducing the amount of construction work, good drainage performance, and reducing construction costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

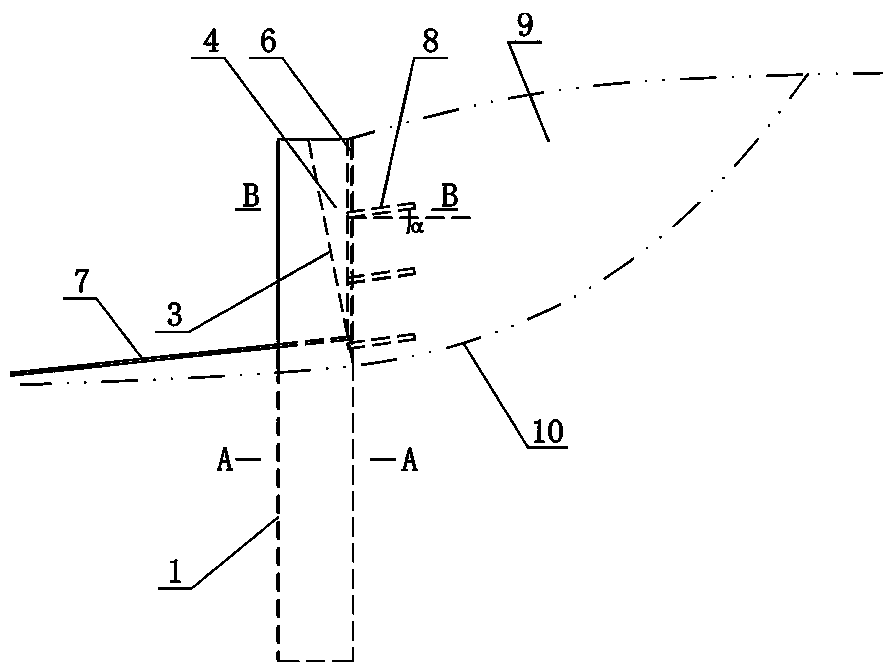

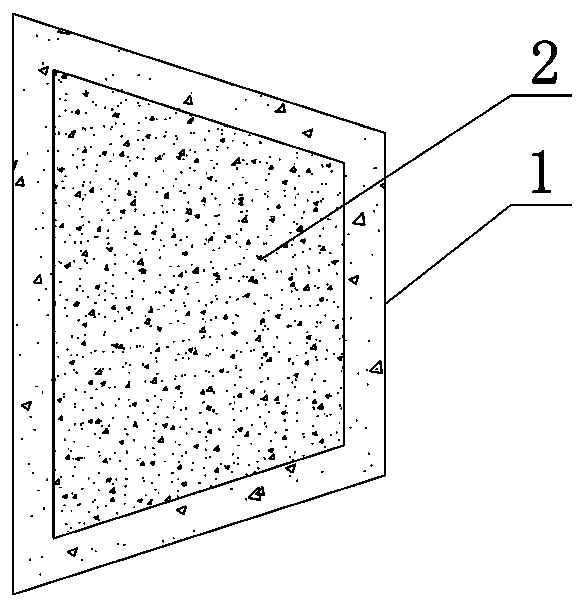

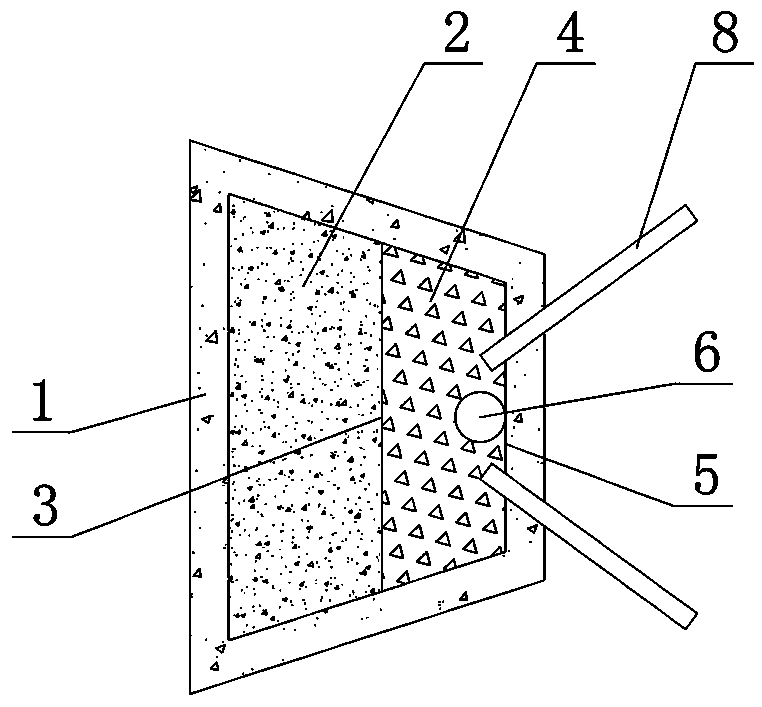

[0024] Such as Figure 1-3 As shown, the special-shaped drainage anti-slide pile according to the present invention includes a pile body 2 covered with an outer retaining wall 1, and the pile body 2 is composed of an embedded section located in the rock-soil body and a cantilever section located above the rock-soil body , the cross-sectional area of the embedded section remains unchanged from bottom to top, the cross-section of the pile body 2 is a trapezoidal structure, the side corresponding to the long side of the trapezoidal structure is the soil-facing surface of the pile body 2, and the short side of the trapezoidal structure corresponds to The side is the soil surface of the pile body 2; from the bottom of the soil surface of the cantilever section to the top of the pile, there is a formwork 3 extending obliquely to the soil surface of the pile body 2, that is, the cross-sectional area of the cantilever section of the pile body is from bottom to top. property reduct...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com