Water-permeable concrete pad and form

a concrete pad and water-permeable technology, applied in the field of concrete pads, can solve the problems of increasing the cost of concrete pads, and reducing the service life of concrete pads,

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] In the following description, terms such as horizontal, upright, vertical, above, below, beneath, and the like, are used solely for the purpose of clarity in illustrating the invention, and should not be taken as words of limitation. The drawings are for the purpose of illustrating the invention and are not intended to be to scale.

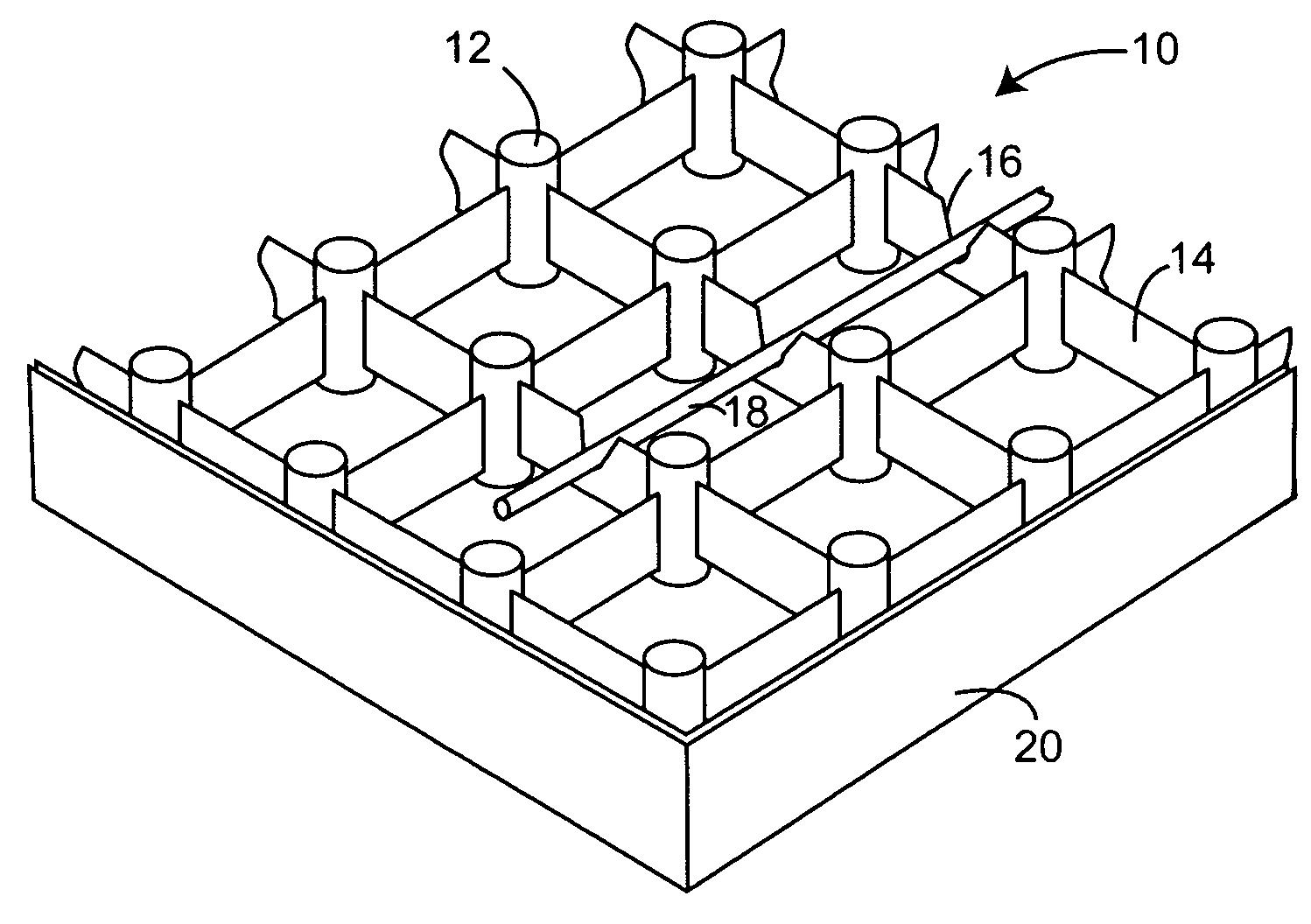

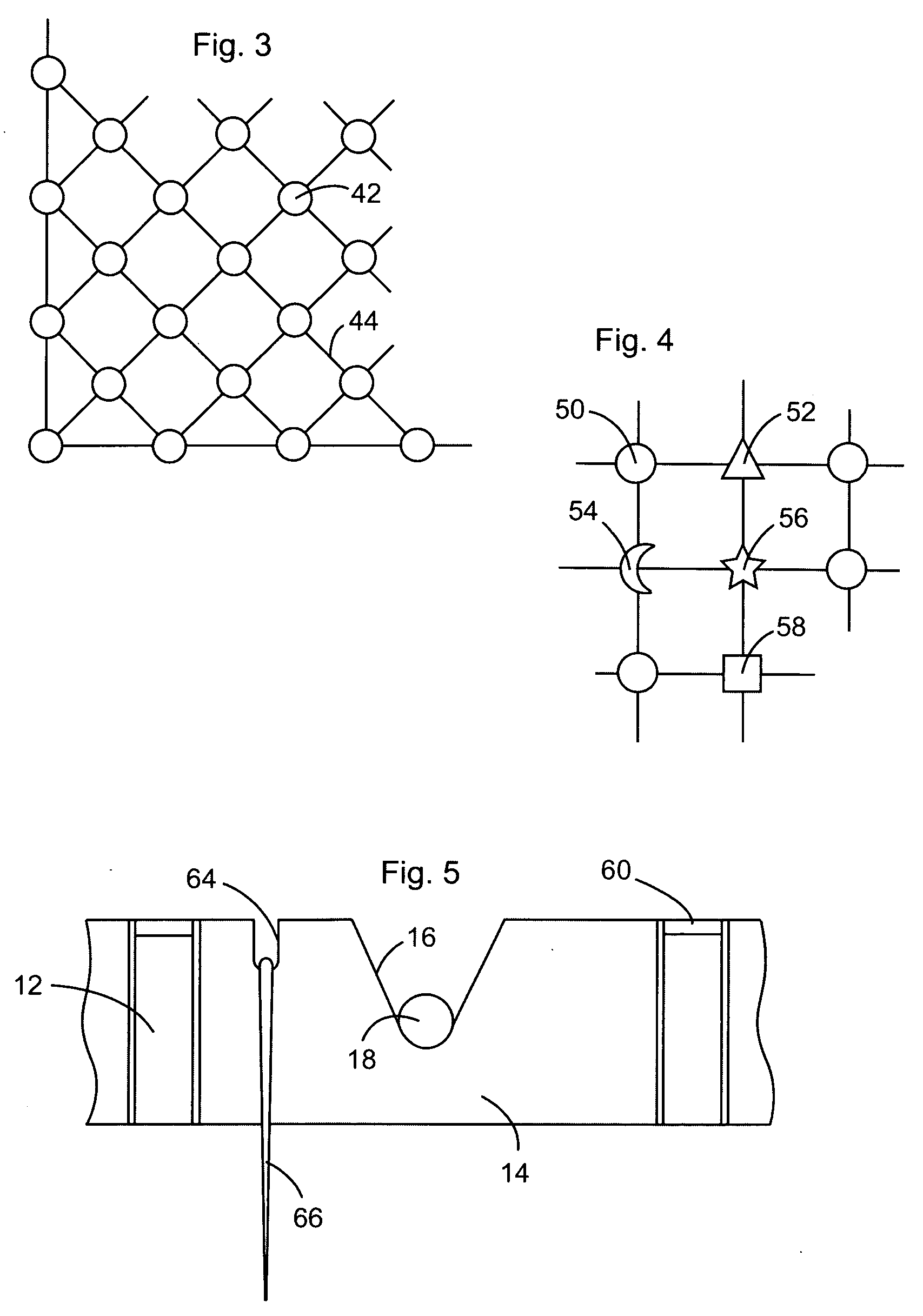

[0030] As best shown in FIG. 1, a preferred embodiment of form, generally 10, is comprised of a plurality of vertical conduits 12 joined by spacers 14 in a rectangular array. Some of spacers 14 may include attachments 16 for positioning of rebar 18. In the embodiment shown, attachment 16 is a V-shaped slot having a lower end approximately one-half the distance between the upper and lower surfaces of form 10. As shown, form 10 is enclosed within a temporary frame 20, which is removed after the poured concrete has cured.

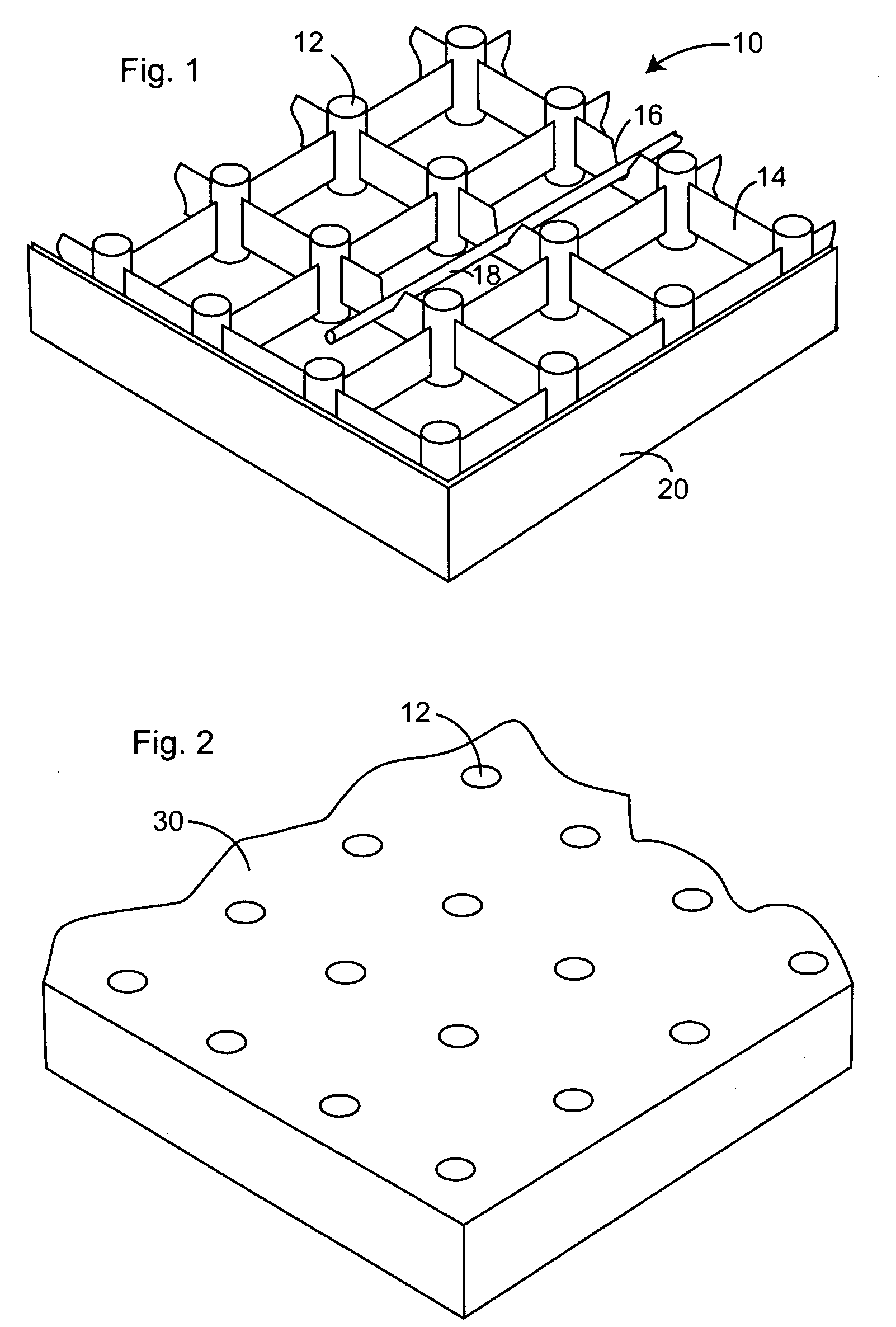

[0031]FIG. 2 illustrates a concrete pad, generally 30, poured using the form illustrated in FIG. 1. The upper ends of conduits 12 o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Shape | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com