Pervious concrete and preparation method thereof

A technology for permeable concrete and concrete, which is applied in sustainable waste treatment, solid waste management, climate sustainability, etc., can solve the problems of extensive utilization of construction waste, limited consumption, and low added value of products. Realize the effect of classification and efficient recycling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

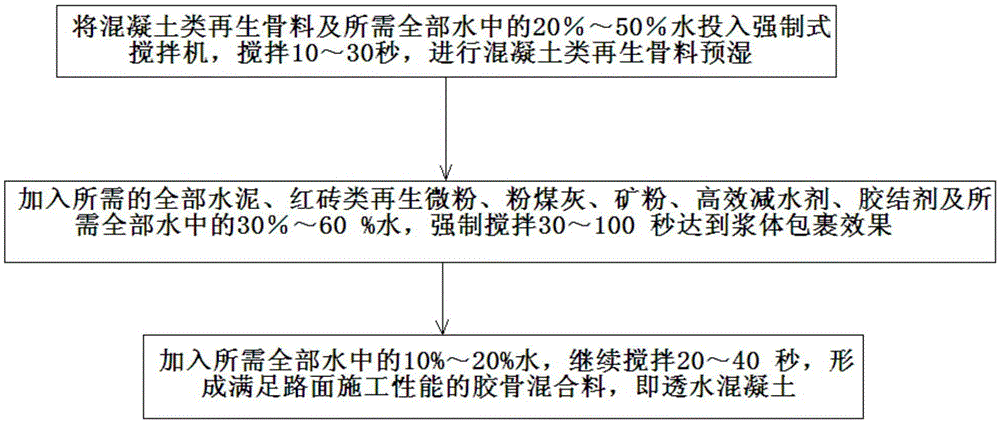

[0017] see figure 1 , based on the same inventive concept, an embodiment of the present invention provides a method for preparing permeable concrete comprising the following steps:

[0018] Step 1: Put the recycled concrete aggregate and 20% to 50% of all required water into a forced mixer, and stir for 10 to 30 seconds to pre-wet the recycled concrete aggregate.

[0019] Step 2, add all required cement, red brick recycled micropowder, fly ash, mineral powder, high-efficiency water reducer, cement and 30% to 60% of all required water, and forcefully stir for 30 to 100 seconds To achieve the effect of slurry wrapping.

[0020] Step 3, adding 10% to 20% of all required water, and continuing to stir for 20 to 40 seconds to form a cementitious mixture that meets the construction performance of the pavement, that is, permeable concrete.

[0021] Step 1 is described in detail.

[0022] The concrete recycled aggregate is obtained from concrete construction waste through crushing, ...

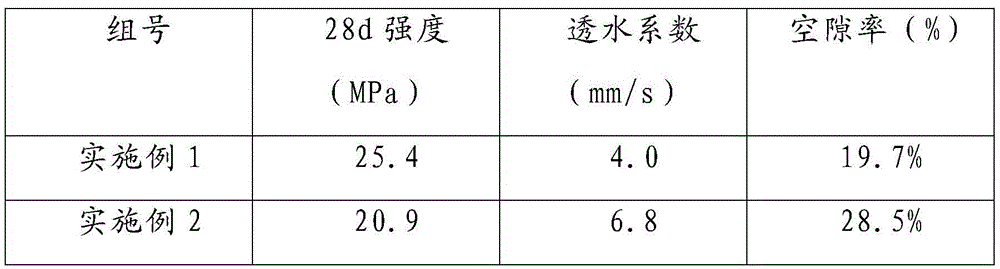

Embodiment 1

[0030] A kind of permeable concrete is composed of the following proportions: waste concrete recycled aggregate: 1500kg / m 3 , water 180kg / m 3 , cement 350kg / m 3 , red brick recycled powder 50kg / m 3 , fly ash 22.5kg / m 3 , mineral powder 22.5kg / m 3 , superplasticizer 5kg / m 3 And cement 5kg / m 3 .

Embodiment 2

[0032] A concrete is composed of the following proportions: waste concrete recycled aggregate: 1500kg / m 3 , water 200kg / m 3 , cement 300kg / m 3 , red brick recycled powder 100kg / m 3 , mineral powder 11.25kg / m 3 , superplasticizer 2.5kg / m 3 , cement 7.5kg / m 3 .

[0033] The preparation method of above-mentioned embodiment 1 and embodiment 2 is:

[0034] 1) Put all the waste concrete recycled aggregate first, put 50% of the water in the required water into the forced mixer according to the water absorption capacity of the concrete recycled aggregate, and stir for 20 seconds;

[0035] 2) According to the amount of binder and the package, add all the required cement, red brick recycled micropowder, fly ash, mineral powder, high-efficiency water reducer, cement and 30% of all required water, and force to stir 40 seconds;

[0036] 3) Add the remaining water in all the required water and continue to stir for 20 seconds to make the mixture achieve suitable working performance;

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Water permeability coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com