Method for performing foundation treatment by using permeable concrete pipe piles

A permeable concrete and foundation treatment technology, which is applied in soil protection, infrastructure engineering, construction, etc., can solve the problems of reducing foundation drainage channels, low foundation strength and bearing capacity, and poor composite foundation effect, so as to reduce the size of the foundation Effects of settlement, reduction of cement consumption, and project cost saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] A method of foundation treatment using permeable concrete pipe piles:

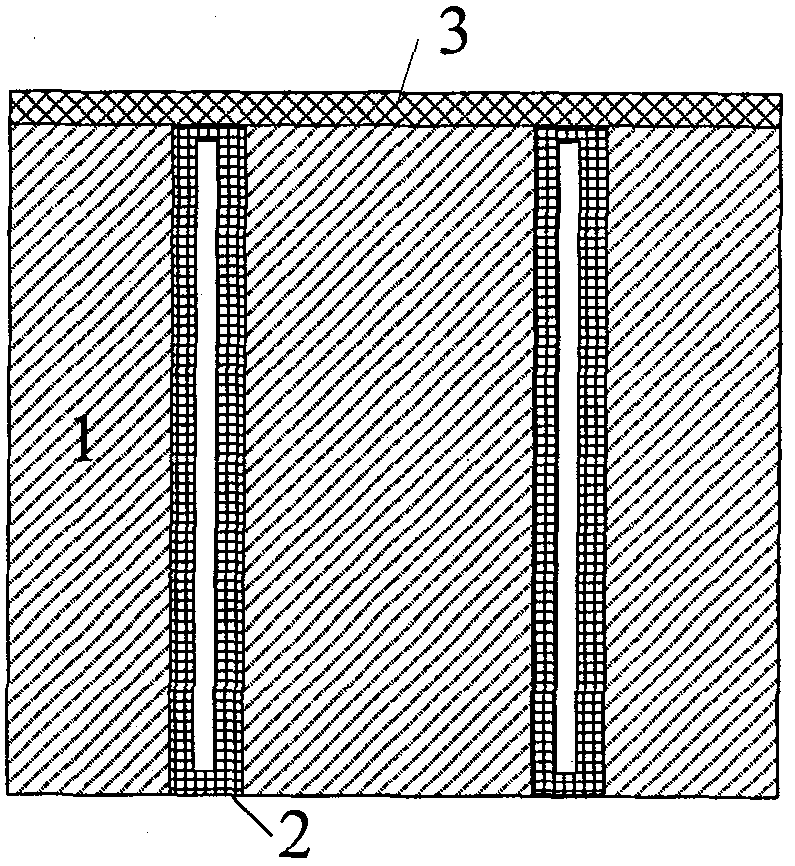

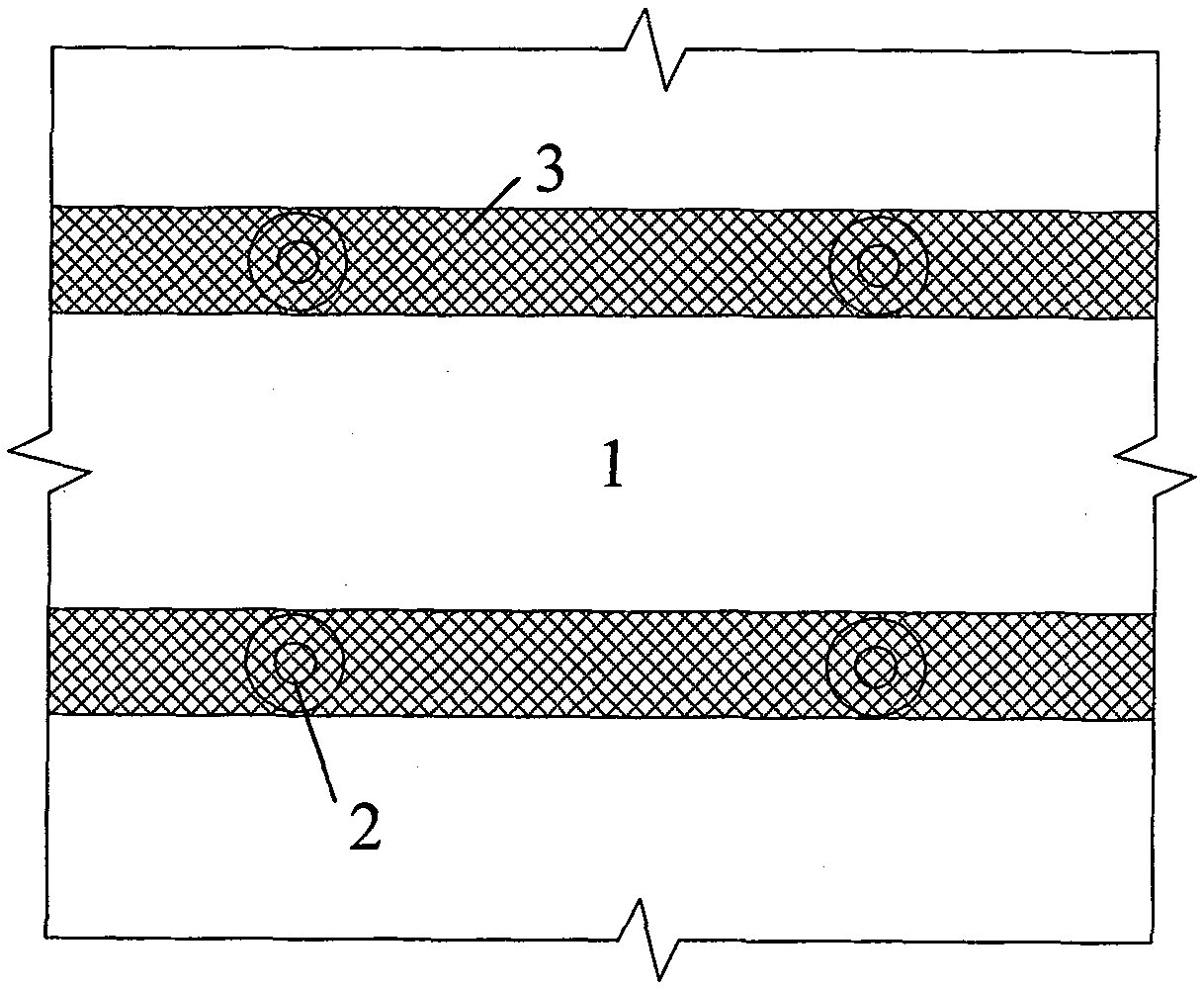

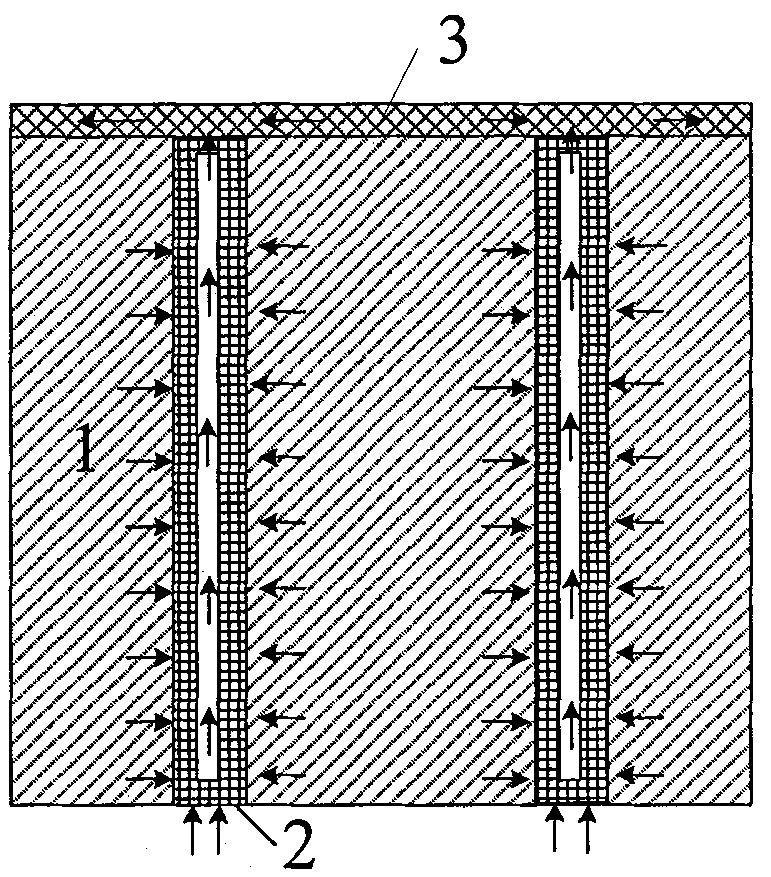

[0018] Choose to arrange permeable concrete pipe piles on soft soil foundation or liquefied foundation. The permeable concrete pipe piles are closed pipe piles with closed ends, and the material of the pile body is permeable concrete. The centers of permeable concrete pipe piles are connected into a straight line, and a cushion is laid along the straight line. The cushion material is sand or gravel. The width of the cushion is equal to the diameter of the pipe pile, and the thickness is 20-40cm.

[0019] In this example

[0020] Permeable concrete pipe piles adopt plum blossom-shaped piles or square piles. The material of the pile body is permeable concrete. The permeability coefficient of the pile body is greater than 1mm / s, and the strength of the pile body is greater than 20MPa. The diameter (outer diameter) of the pipe pile is 20-40cm, and the wall thickness is 5-10cm.

[0021] Such as figur...

Embodiment 2

[0025] Such as figure 1 , figure 2 The permeable concrete pipe pile composite foundation shown in the example uses prefabricated pipe piles and uses static pressure construction on site. The specific methods are as follows:

[0026] 1) The diameter (outer diameter) of the pipe pile is 20cm, the wall thickness is 5cm, and the pile length is 8m. The mix ratio and reinforcement of the concrete are determined according to the design requirements. The pipe pile is demoulded and cured until the specified time. Quality testing is required.

[0027] 2) Level the site, the pile spacing is 2m, the piles are arranged in a square, and the piles are pressed by conventional pile pressing machines. If the strength of the permeable concrete pipe pile is low and the pile body is damaged during the pile pressing process, the pile position can be pre-drilled by vibrating sinking tube or long screw method, and the hole diameter and hole depth are slightly smaller than the pile diameter and pi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com