Nano photocatalysis porous concrete product and preparation method thereof

A technology of permeable concrete and nano-light, which is applied in the field of nano-photocatalytic permeable concrete products and its preparation, can solve the problems of small internal surface area, long contact time, and short contact time, and achieve high photocatalytic degradation of NOX efficiency, large contact area, The effect of high photocatalytic efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

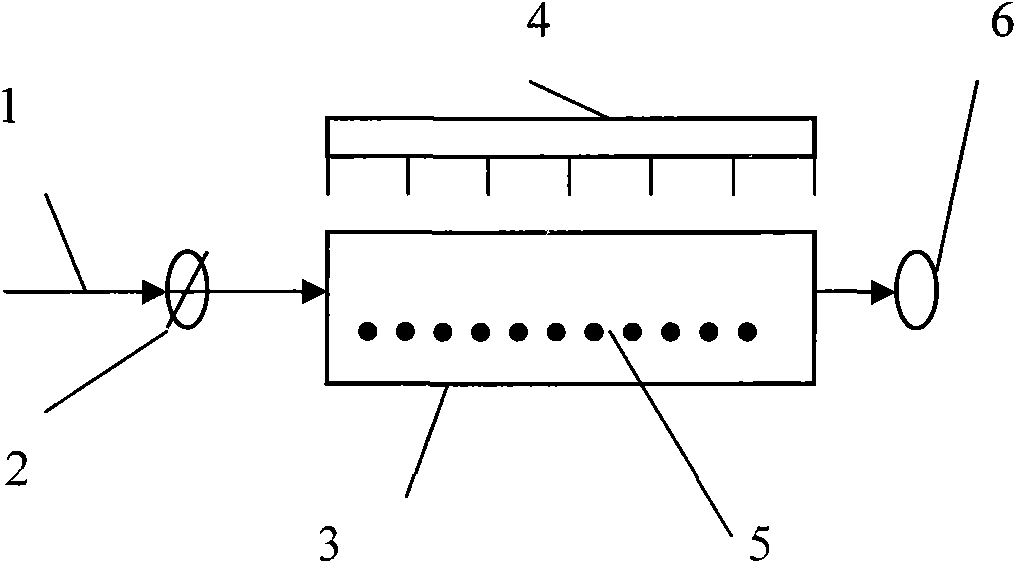

Image

Examples

Embodiment 1

[0027] Embodiment 1: Preparation of nitrogen-doped nano-titanium dioxide powder

[0028] Get 100g of anatase-type nano-titanium dioxide powder (P25, Shanghai Kaiyin Chemical Co., Ltd.), and take 10.34g of ammonium sulfate as 1:8 according to the material ratio of nitrogen and titanium, mix it and load it into a ball mill for 2 hours, and set the speed of the ball mill at 500-600 revolutions per minute;

[0029] Put the ball-milled powder in a muffle furnace, raise the temperature to 600°C, keep it warm for 5 hours, and get nitrogen-doped nano-titanium dioxide powder after cooling, which is ready for use.

Embodiment 2

[0031] Use 42.5-grade ordinary cement, natural sand with a gradation of 0.15-4.75mm that meets the requirements of national standards, SN-II naphthalene-based high-efficiency water reducer (Hangzhou Construction Engineering Building Materials Co., Ltd.) and water, according to aggregate: cement: water: Water reducer = 3.5:1:0.31:0.025 Prepare and stir to obtain ordinary concrete mixture, which is mechanically pressed to form a dense concrete product with a size of 60mm×100mm×200mm.

[0032] Using anatase nano-TiO 2 (P25) as photocatalyst, adopt SN-II naphthalene series high-efficiency water reducer (Hangzhou Construction Engineering Building Materials Co., Ltd.) as dispersant, the dosage of dispersant is 2.5% of P25 quality, add the measured P25 and dispersant into water, After stirring evenly, use a planetary ball mill to mill for 1 hour to obtain nano-TiO with a mass concentration of 5%. 2 Dispersions.

[0033] After dense concrete products are cured for 1 day, nano-TiO wi...

Embodiment 3

[0035] Use 42.5-grade ordinary cement, single-grain natural sand with a gradation of 0.3-0.6mm, SN-II naphthalene-based high-efficiency water-reducing agent (Hangzhou Construction Engineering Building Materials Co., Ltd.) and water, according to aggregate: cement: water: water-reducing Agent = 3.0: 1: 0.30: 0.025 was prepared and stirred to obtain a permeable concrete mixture, which was mechanically pressed to form a permeable concrete product with a size of 60mm×100mm×200mm.

[0036] Using anatase nano-TiO 2 (P25) as photocatalyst, adopt SN-II naphthalene series high-efficiency water reducer (Hangzhou Construction Engineering Building Materials Co., Ltd.) as dispersant, the dosage of dispersant is 2.5% of P25 quality, add the measured P25 and dispersant into water, After stirring evenly, use a planetary ball mill for 1 hour to obtain nano-TiO with a mass concentration of 2%. 2 Dispersions.

[0037] After curing permeable concrete products for 1 day, use nano-TiO with a mass...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com