High-strength water-permeable concrete floor brick and its production method

A technology of permeable concrete and floor tiles, applied in floors, buildings, building structures, etc., can solve the problems of wasting clay resources and wasting energy, and achieve good freeze-thaw resistance, resource saving, good cooling and heat insulation effects Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

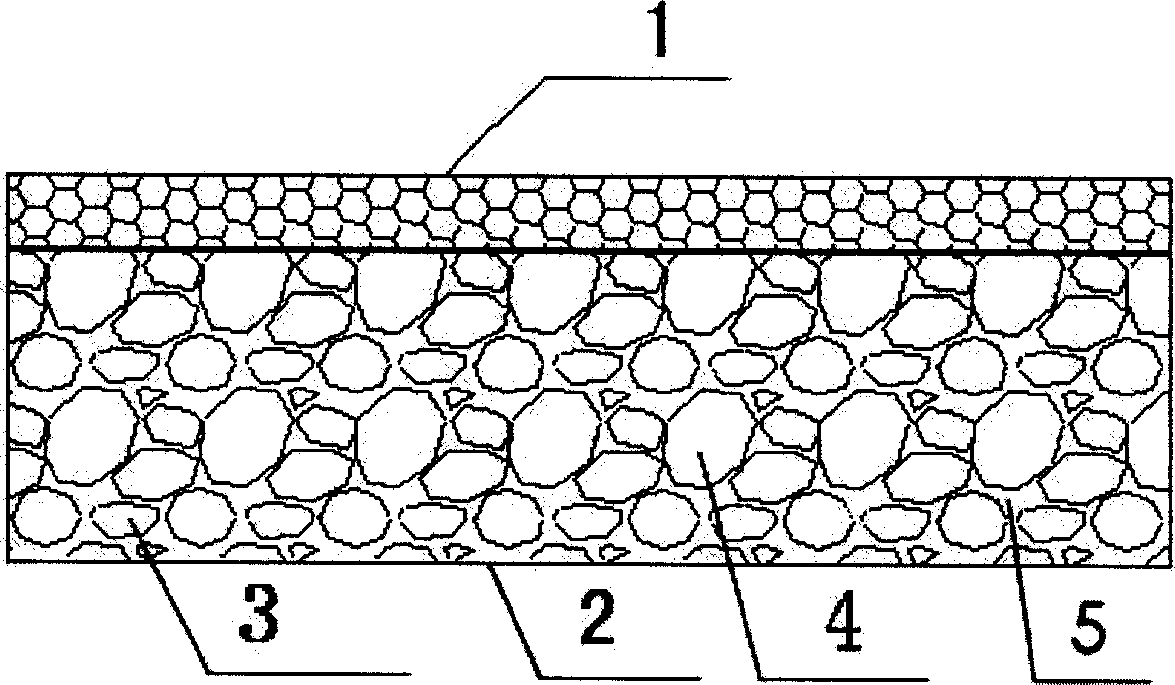

[0052] See the accompanying drawings for the embodiment: This high-strength permeable concrete pavement brick is composed of a base layer 2 and a surface layer 1. The base layer 2 includes small crushed stones 3 and large crushed stones 4, and the cement slurry is wrapped on the aggregate surface composed of large and small crushed stones. , The pores 5 between the aggregates form water-permeable channels. The weight ratio of the base layer is as follows:

[0053] Examples of cement selection: 18%, 19%, 20%, 21%.

[0054] Among them, not more than 30% of cement can be replaced by slag or fly ash.

[0055] Examples of the selection of 3-5mm small gravel: 50%, 51%, 52%, 53%, 54%, 55%;

[0056] Examples of the selection of 7-10mm large gravel: 18%, 19%, 20%, 21%.

[0057] The weight ratio of the above-mentioned 7-10mm large crushed stones to 3-5mm small crushed stones is 1:2, 1:3, 1:4, 1:5, 1:6, 1:7, 1:8, 1:9, 1:10. The size ratio of large particles and small particles can b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com