Drilling fluid for protecting coal bed against collapse

A drilling fluid and coal seam technology, applied in the field of coalbed methane exploration, can solve the problems of large economic losses, damage to coal seams, buried drilling tools, etc., and achieve the effects of small damage, reduced complex accidents, and high-efficiency mining

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

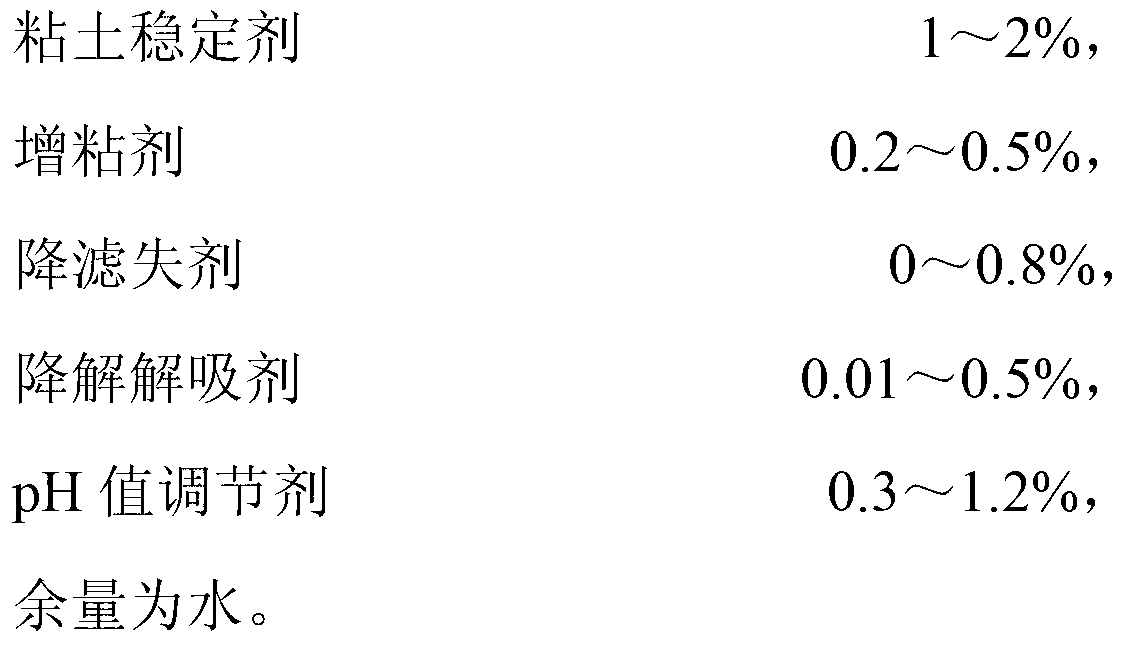

[0020] A drilling fluid for protecting coal seams from collapsing is made of the following components by weight percentage:

[0021]

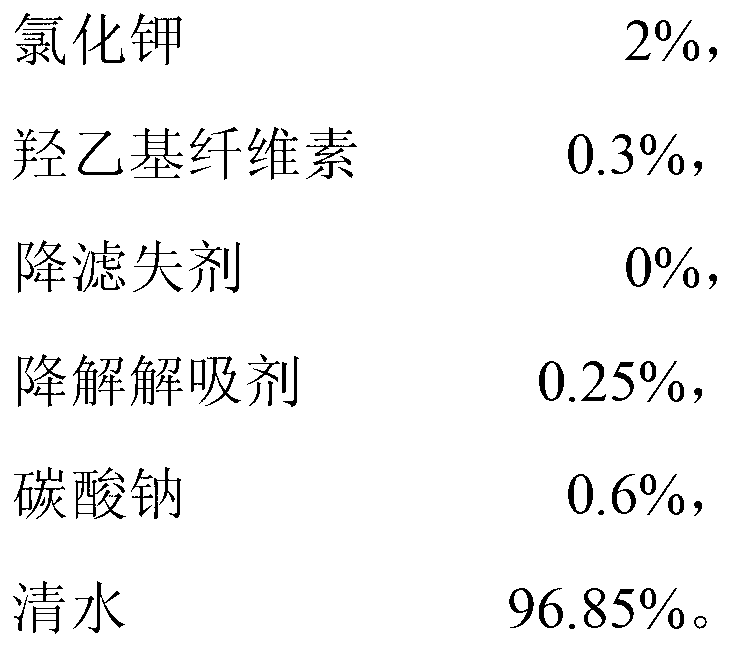

[0022] The degradation desorbent used is a mixture of ammonium persulfate and sodium hypochlorite solution, and the weight percentage composition of the two is 60% and 40% respectively.

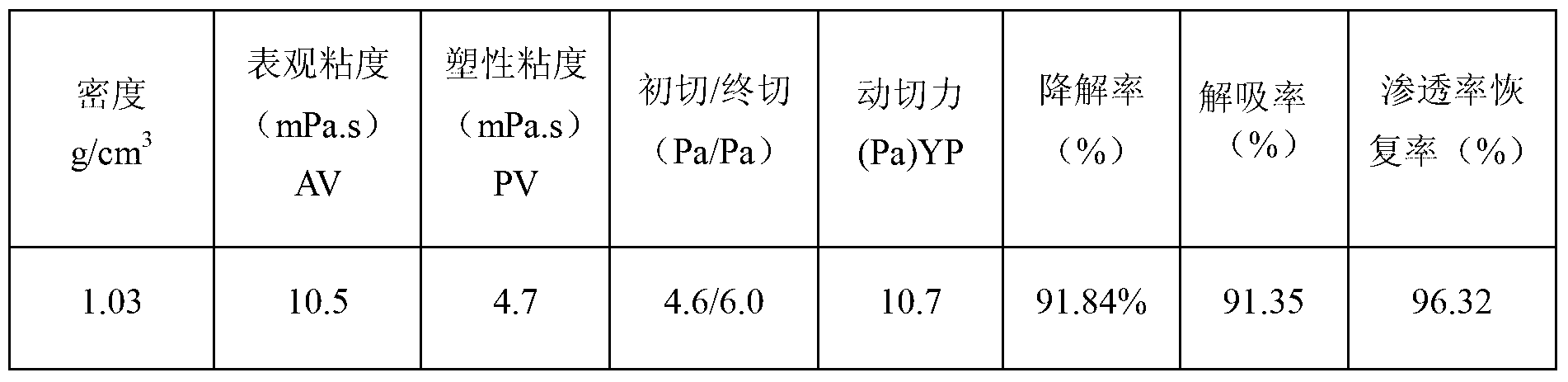

[0023] Weigh each component according to the above ratio, and mix thoroughly to obtain a density of 1.03g / cm 3 The performance index of the drilling fluid is shown in the table below:

[0024]

Embodiment 2

[0026] A drilling fluid for protecting coal seams from collapsing is made of the following components by weight percentage:

[0027]

[0028] Wherein the weight percent composition of fluid loss reducer is as follows:

[0029] Sodium Carboxymethyl Cellulose 90%

[0030] Polyanionic Cellulose 10%.

[0031] The degradation desorbent is a mixture of ammonium persulfate and sodium hypochlorite solution, and the weight percentage composition of the two is 90% and 10% respectively.

[0032] Weigh each component according to the above ratio, and mix thoroughly to obtain a density of 1.03g / cm 3 drilling fluid. The performance index of the drilling fluid is shown in the table below:

[0033]

Embodiment 3

[0035] A drilling fluid for protecting coal seams from collapsing is made of the following components by weight percentage:

[0036]

[0037] Wherein the weight percent composition of fluid loss reducer is as follows:

[0038] Sodium Carboxymethyl Cellulose 85%

[0039] Polyanionic Cellulose 15%

[0040] The degradation desorbent is a mixed solution of ammonium persulfate and sodium hypochlorite solution, and the composition of the two is 70% and 30% by weight respectively.

[0041] After mixing the above raw materials, the density is 1.02g / cm 3 The performance index of the drilling fluid is shown in the table below:

[0042]

[0043] In the above examples, density, apparent viscosity, plastic viscosity, initial shear, final shear and dynamic shear force are conventional performance indicators of drilling fluid. By adjusting the formula of the drilling fluid, drilling fluids with different densities can be obtained, which can effectively reduce leakage an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com