Environment-friendly profile and manufacturing method thereof

A production method and an environmentally friendly technology, which is applied to flat products, other household appliances, wood processing appliances, etc., can solve the problems of high cost, low strength, and affecting the life safety of relevant personnel, and achieve the effect of light weight and high strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

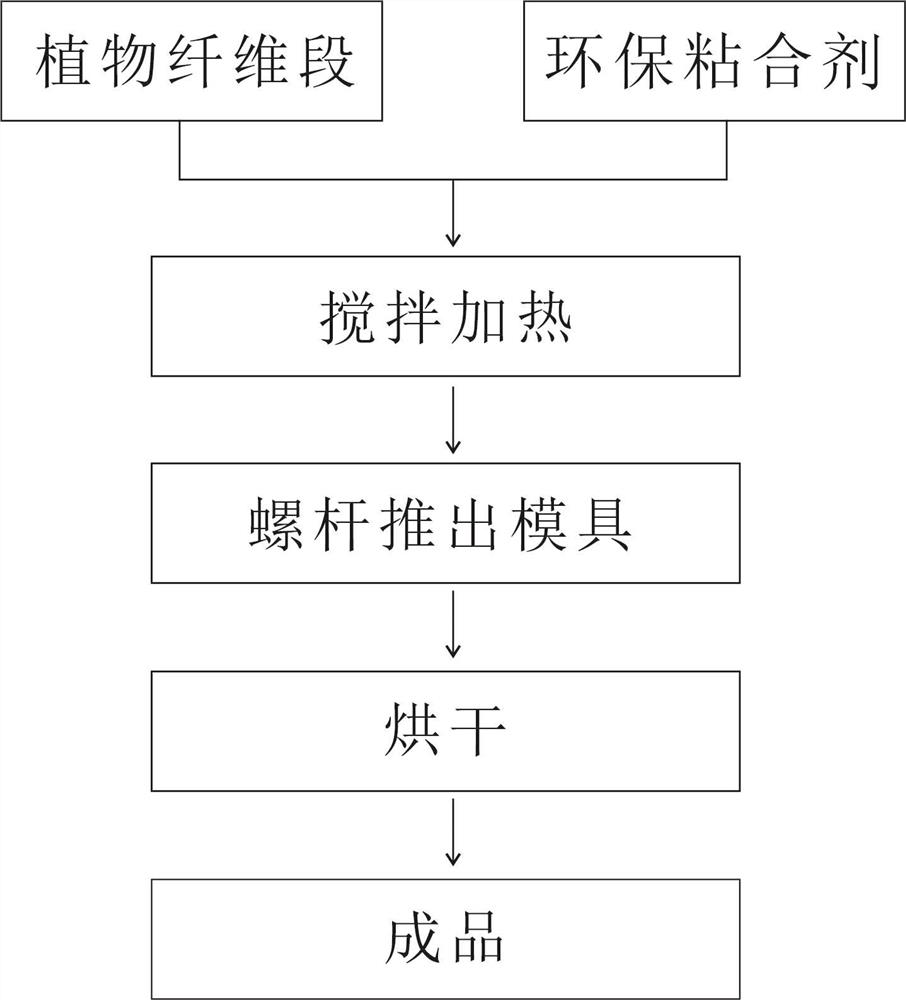

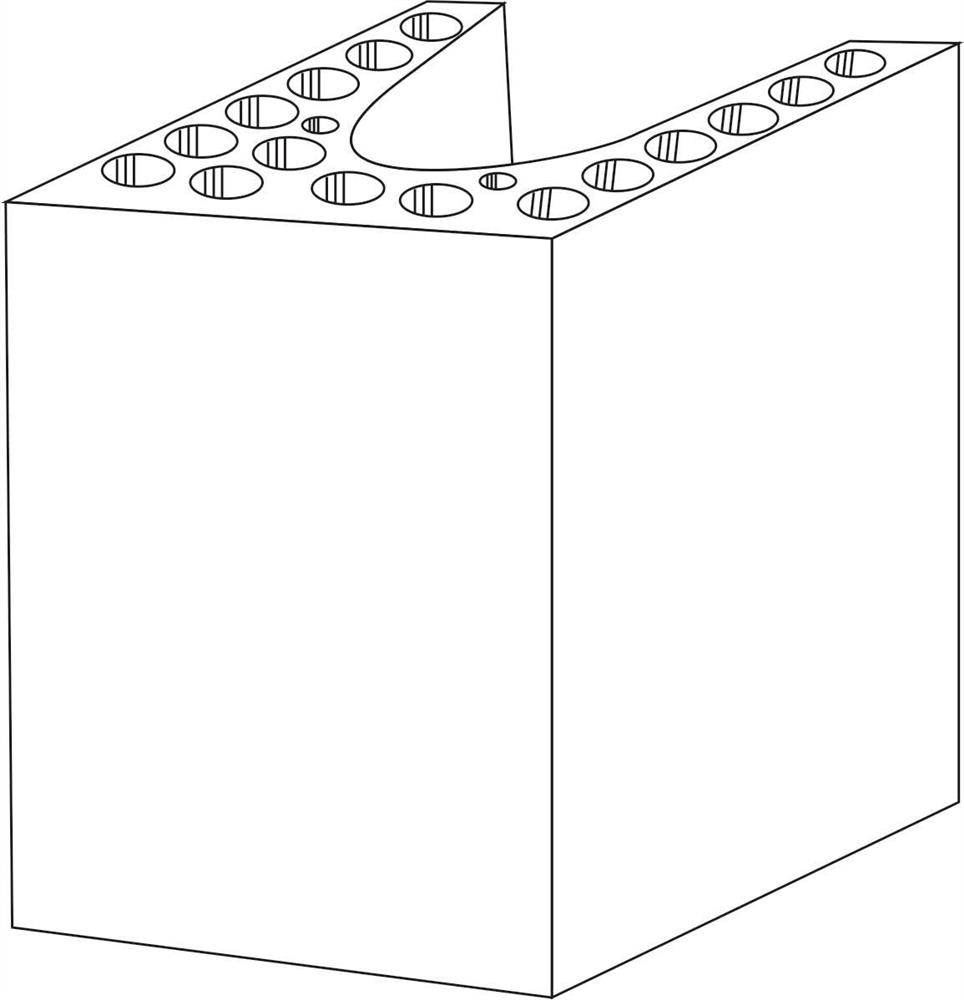

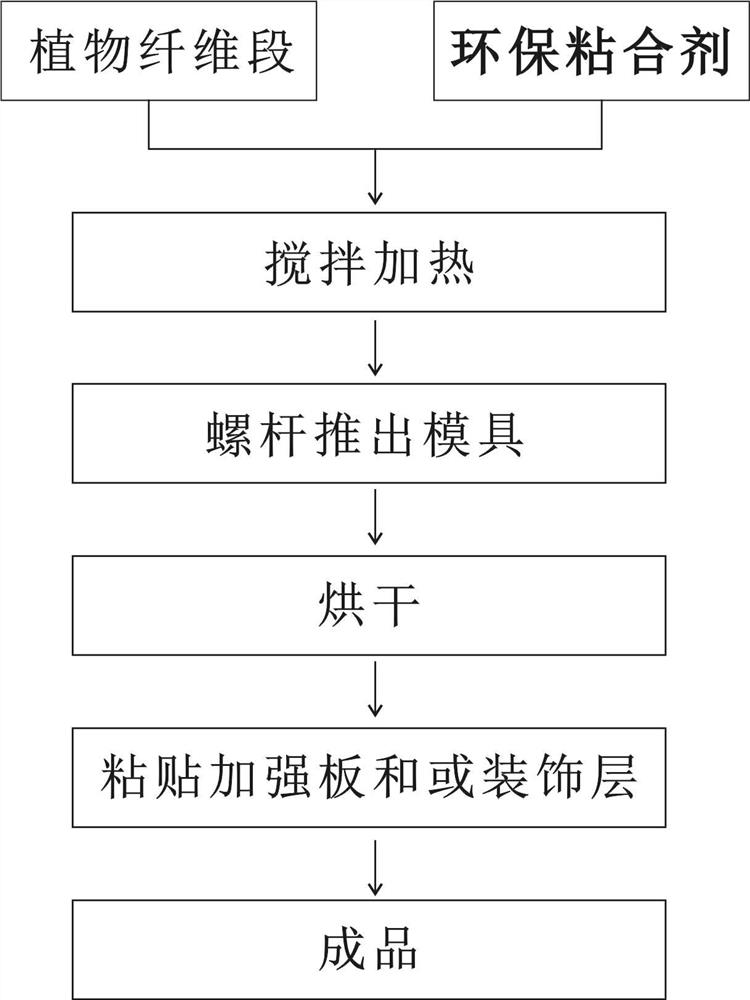

[0018] Example 1: See figure 1 and figure 2 As shown, it is a flow chart of steps and a finished product completion diagram of the environmental protection profile production method provided by the present invention, and its steps include:

[0019] Step 1: Stir the plant fiber segment, starch-based modified rubber powder, or other environmentally friendly adhesives that do not pollute the environment through a mixer to form raw materials; the plant fiber segment can be ground into various sizes of granules or cuts according to the needs of use. Segment or thread; the material of the plant fiber segment can be corn stalk; the plant fiber segment can be mixed with corn stalk and other plants at the same time, such as: wheat straw, rice, coconut shell, cotton stalk, weed branches, waste wood Chips and other plants; the weight percentage of each component of the raw material in the mixture is: plant fiber powder 5-80%, environmental adhesive 5-80%;

[0020] Step 2: Stir and hea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com