Permeable concrete

A technology of permeable concrete and parts by weight, applied in the field of concrete, can solve the problems of restricting the application of permeable concrete and low strength, and achieve the effects of excellent water permeability, improved strength and high mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

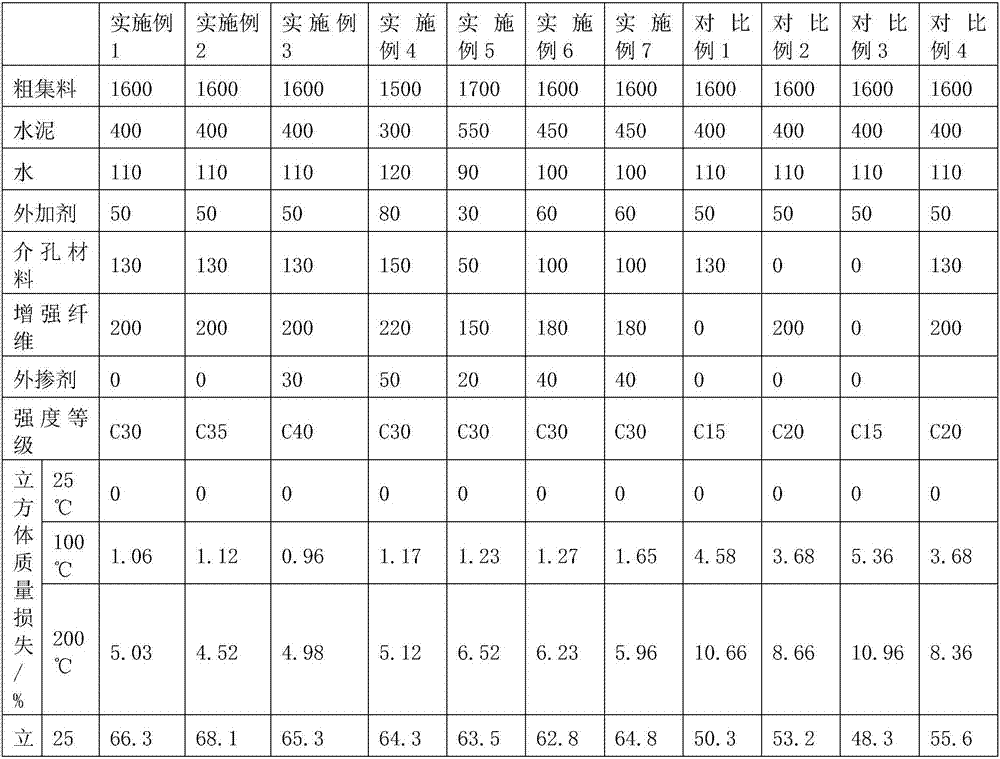

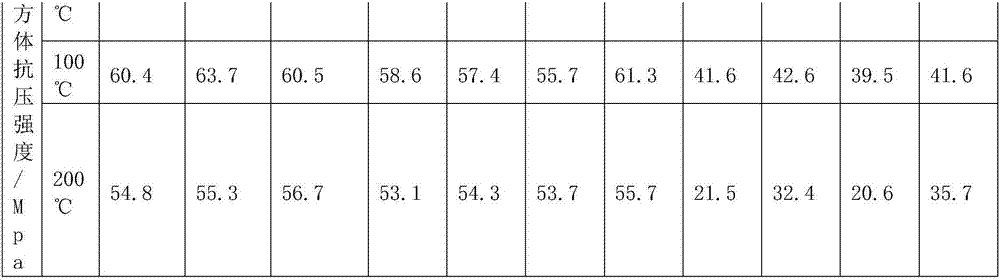

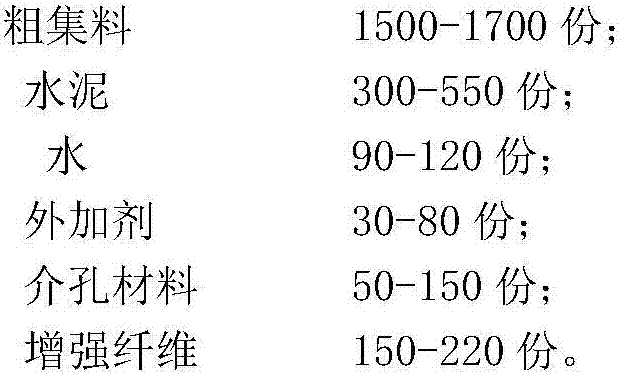

[0023] Embodiment 1: A kind of permeable concrete, including coarse aggregate, cement, water, admixture, mesoporous material, reinforcing fiber. In terms of parts by weight, refer to Table 1 for the above components. Among them, artificial crushed stone with a particle size of 5-10mm is selected as the coarse aggregate. The mesoporous material is silicon-based mesoporous material, and the reinforcing fiber is nano-carbon fiber. The additive is slaked lime.

[0024] The preparation method of the permeable concrete is as follows: Weigh the mesoporous material, reinforcing fiber, and water in the formulated amount, mix them evenly, then put in the cement, coarse aggregate, and admixture in the formulated amount, and mix to obtain the permeable concrete.

[0025] Concrete compressive strength test: Refer to the GB50204-2015 Concrete Structure Engineering Construction Quality Acceptance Code to detect the grade of compressive strength of permeable concrete, and list the test resu...

Embodiment 2

[0027] Embodiment 2: a kind of permeable concrete, the difference from embodiment 1 is that the admixture is 25 parts of nano silicon dioxide and 25 parts of nano calcium carbonate. The concrete compressive strength test and concrete high temperature performance test were carried out with reference to Example 1, and the results are listed in Table 1.

Embodiment 3

[0028] Embodiment 3: a kind of permeable concrete, the difference from embodiment 2 is that 30 parts of external admixtures are added to the permeable concrete.

[0029] The preparation method of the permeable concrete is as follows: Weigh the mesoporous material, reinforcing fiber, and water in the formulated amount, mix them evenly, and then put in the formulated amount of cement, coarse aggregate, admixture, and external admixture, and obtain the permeable concrete after stirring. With reference to the method in Example 1, the concrete compressive strength test and concrete high temperature performance test were carried out, and the results are listed in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com