Semi-flexible pavement material and pavement construction method thereof

A technology of semi-flexible pavement and construction method, which is applied to the coagulation pavement, roads, roads and other directions paved on site. In order to improve the overall strength and deformation ability, prevent the delamination of sand and mortar, and prolong the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

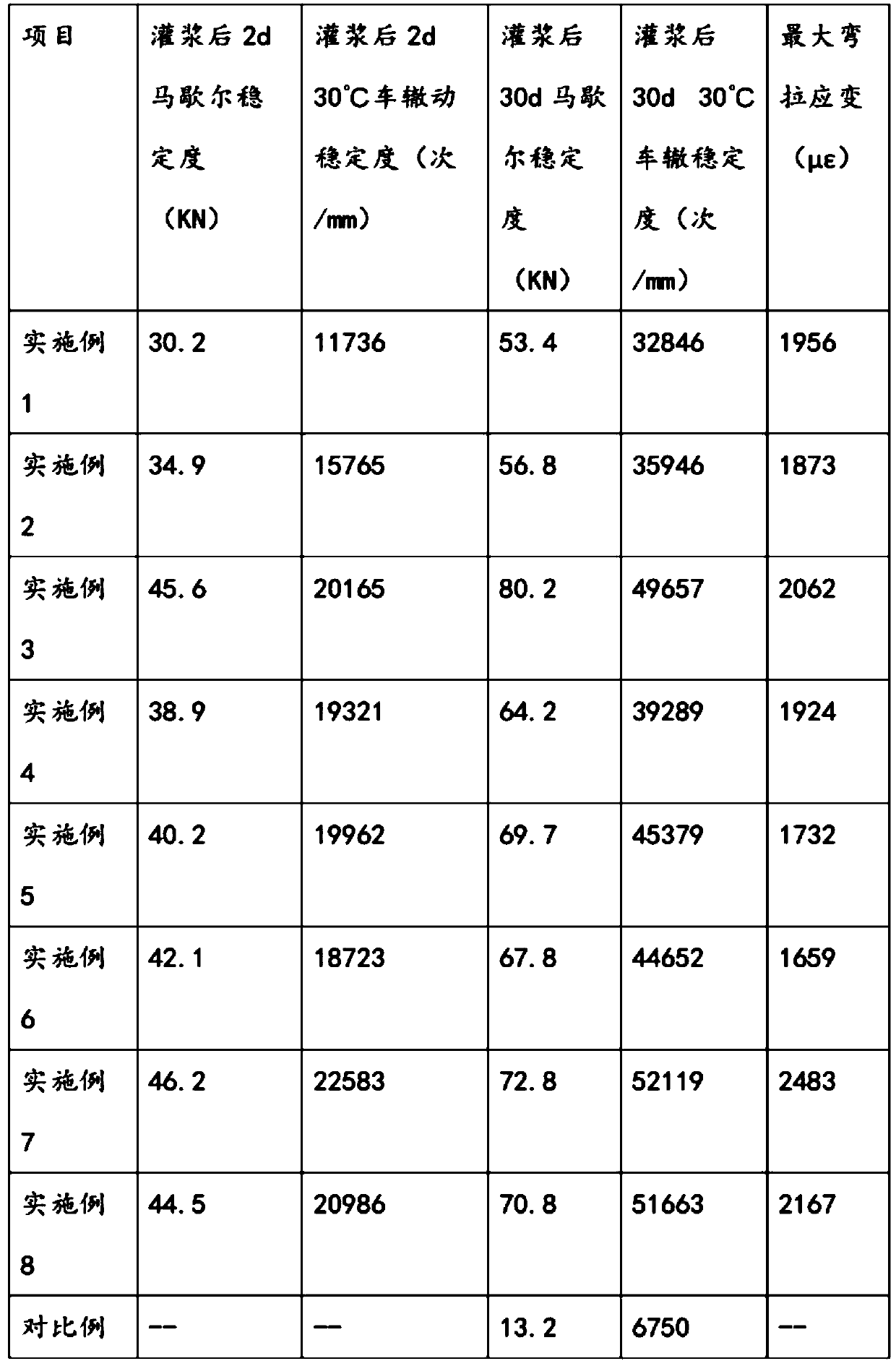

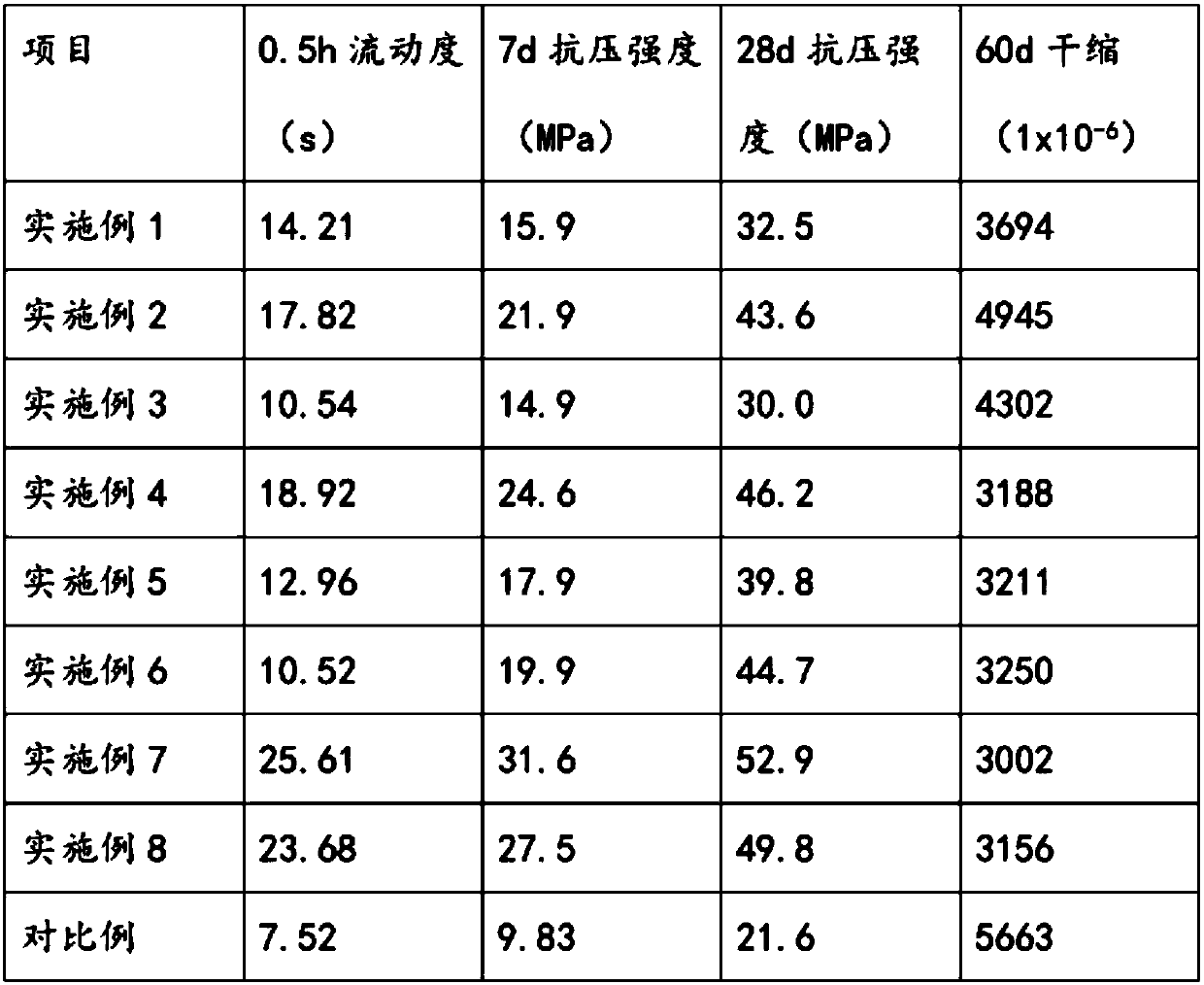

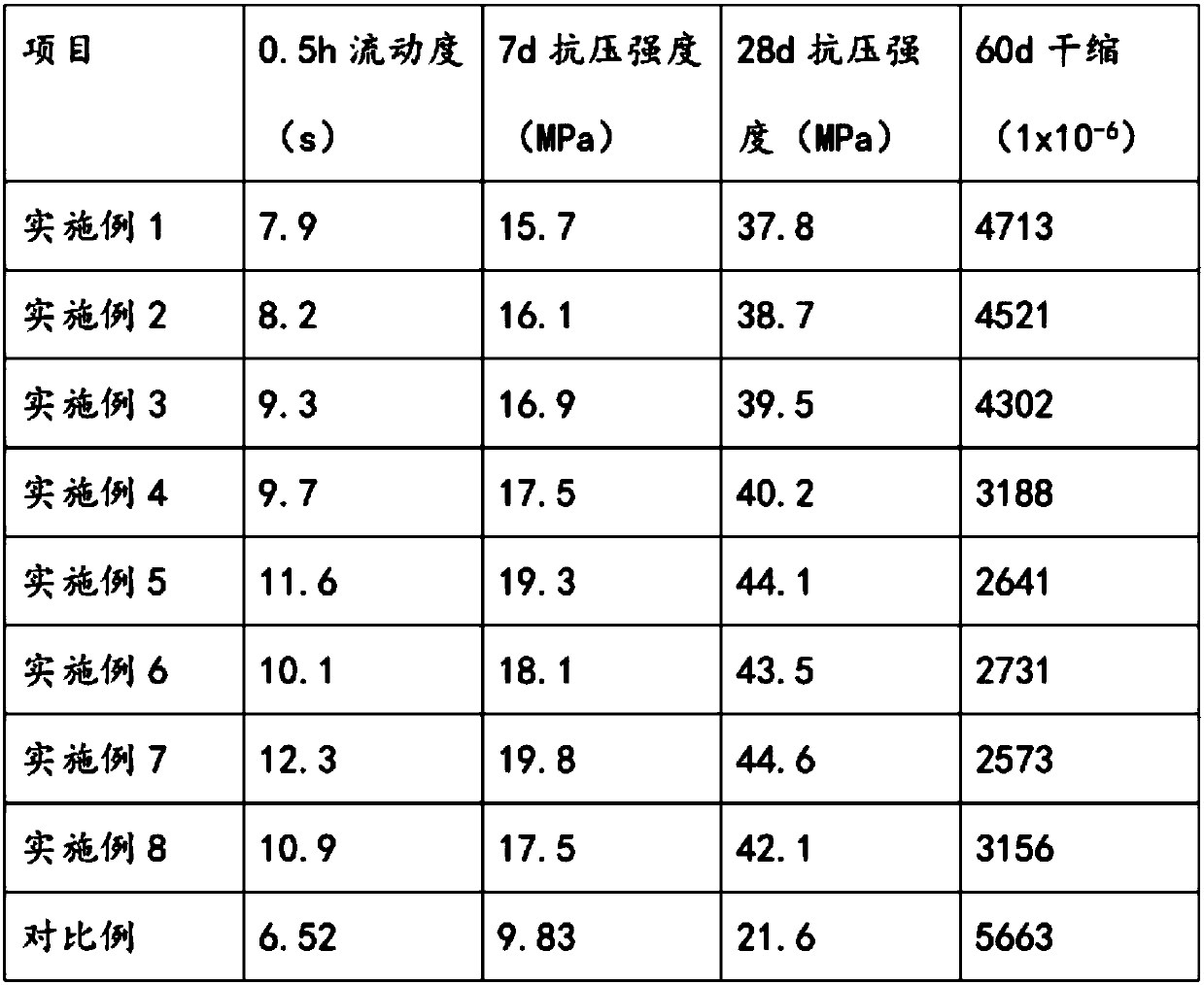

Examples

Embodiment 1

[0046] Preparation of asphalt mixture: First, mix SBS modified asphalt, coarse aggregate, fine aggregate, water, limestone powder, and lithium salt composite early strength agent according to the ratio of 1:4.5:0.55:0.22:0.42:0.001 , and then stir well. Then pave the mixed asphalt mixture on the road surface, the paving thickness is 7cm, the paving speed is 1m / min, and the porosity of the asphalt mixture is about 25%. Then cure for 2 hours.

[0047] Preparation of cement mortar: add 1 part of 425 grade aluminate cement, 0.05 part of fly ash, and 0.2 part of ultra-fine sand into the cement mortar mixer in sequence, mix for 2 minutes until uniform, then add 0.4 part of water, UEA to expand Add 0.05 parts of water reducing agent, 0.4 parts of naphthalene-based superplasticizer, 0.01 parts of polyvinyl alcohol, and 0 parts of BD emulsion into the cement mortar mixer and stir for 4 minutes.

[0048] Preparation of semi-flexible pavement: Spread the well-mixed cement mortar repeat...

Embodiment 2

[0050] Preparation of asphalt mixture: First, mix SBS modified asphalt, coarse aggregate, fine aggregate, water, limestone powder, and lithium salt composite early strength agent according to the ratio of 1:4.7:0.6:0.25:0.43:0 , and then stir well. Then spread the mixed asphalt mixture on the road surface, the paving thickness is 5cm, the paving speed is 1.5m / min, and the porosity of the asphalt mixture is about 29%. Then cure for 3 hours.

[0051] Preparation of cement mortar: Then add 1 part of 425 grade aluminate cement, 0.1 part of fly ash, and 0.2 part of ultra-fine sand into the cement mortar mixer and mix them for 2 minutes until uniform, then add 0.45 parts of water, UEA Add 0.05 part of expansion agent, 0.5 part of naphthalene-based water reducer, 0.02 part of polyvinyl alcohol, and 0.1 part of BD emulsion into the cement mortar mixer and stir for 4 minutes.

[0052] Preparation of semi-flexible pavement: Spread the well-mixed cement mortar repeatedly on the surface...

Embodiment 3

[0054] Preparation of asphalt mixture: First, mix SBS modified asphalt, coarse aggregate, fine aggregate, water, limestone powder, and lithium salt composite early strength agent according to the ratio of 1:4.9:0.72:0.29:0.48:0.0015 , and then stir well. Then pave the mixed asphalt mixture on the road surface, the paving thickness is 7cm, the paving speed is 2m / min, and the porosity of the asphalt mixture is about 30%. Then cure for 2 hours.

[0055] Preparation of cement mortar: First, mix naphthalene-based water reducer and methyl cellulose ether at a weight ratio of 1:0.003, and make a uniform mixture by continuous stirring for later use. Then add 1 part of 425 grade aluminate cement, 0.2 parts of fly ash, and 0.25 parts of ultra-fine sand into the cement mortar mixer and mix them for 2 minutes until uniform. Then add 0.55 parts of water, 0.08 parts of UEA expansion agent, naphthalene Add 0.6 parts of superplasticizer, 0.04 parts of polyvinyl alcohol, and 0.3 parts of BD ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com