Semi-flexible composite pavement structure and preparation method thereof

A composite pavement, semi-flexible technology, applied in the field of semi-flexible composite pavement structure and its preparation, can solve the problems of poor driving comfort, many seams, rutting, etc., to overcome the problems of poor driving comfort, good road performance and high cost performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

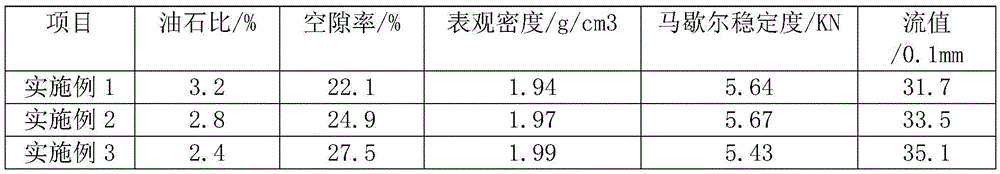

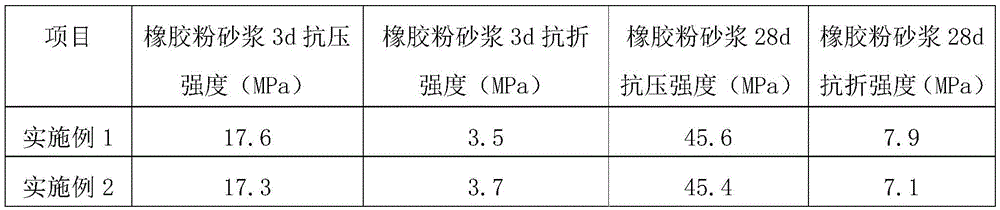

Embodiment 1

[0022] The semi-flexible composite pavement structure of the present invention includes the following components: 70% of the large-pore asphalt mixture matrix, 30% of rubber powder cement mortar;

[0023] The macroporous asphalt mixture matrix is formed by mixing coarse aggregate, fine aggregate, active mineral powder and asphalt, wherein the coarse aggregate and fine aggregate are diabase or limestone, and the porosity of the mixture is 22%; The asphalt is SBS (I-D) modified asphalt, the asphalt ratio is 3.2%; the active ore powder is manganese slag ore powder, which is made of blast furnace water-quenched manganese iron slag, and after 20rain grinding under ethanolamine grinding aid The formed mineral powder, the main components of the manganese slag mineral powder are SiO and CaO, has pozzolanic activity, and the dosage is 3%; the particle size of the coarse aggregate is 5-16mm, and the particle diameter of the fine aggregate is 0-5mm , the particle size of the active min...

Embodiment 2

[0032] The semi-flexible composite pavement structure of the present invention includes the following components: 75% of the large-pore asphalt mixture matrix, 25% of rubber powder cement mortar;

[0033] The macroporous asphalt mixture matrix is formed by mixing coarse aggregate, fine aggregate, active mineral powder and asphalt, wherein the coarse aggregate and fine aggregate are diabase or limestone, and the porosity of the mixture is 25%; The asphalt is SBS (I-D) modified asphalt, the asphalt ratio is 2.8%; the active ore powder is manganese slag ore powder, which is made of blast furnace water-quenched manganese iron slag, after 20rain grinding under ethanolamine grinding aid The formed mineral powder, manganese slag mineral powder is mainly composed of SiO and CaO, has pozzolanic activity, and the dosage is 2.5%; the particle size of the coarse aggregate is 5-16mm, and the particle diameter of the fine aggregate is 0-5mm , the particle size of the active mineral powder...

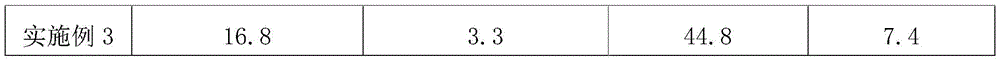

Embodiment 3

[0042] The semi-flexible composite pavement structure of the present invention includes the following components: 80% of the large-pore asphalt mixture matrix, 20% of rubber powder cement mortar;

[0043] The macroporous asphalt mixture matrix is formed by mixing and stirring coarse aggregate, fine aggregate, active mineral powder and asphalt, wherein the coarse aggregate and fine aggregate are diabase or limestone, and the porosity of the mixture is 28%; The asphalt is SBS (I-D) modified asphalt, the asphalt ratio is 2.4%; the active ore powder is manganese slag ore powder, which is made of blast furnace water-quenched manganese iron slag, after 20rain grinding under ethanolamine grinding aid The formed mineral powder, manganese slag mineral powder is mainly composed of SiO and CaO, has pozzolanic activity, and the dosage is 2.0%; the particle size of the coarse aggregate is 5-16mm, and the particle diameter of the fine aggregate is 0-5mm , the particle size of the active m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com