Self-compact concrete with oversized-particle aggregate and construction technology thereof

A technology of self-compacting concrete and large particle size, which is applied in the field of super-large particle size aggregate self-compacting concrete and its construction technology, can solve problems such as low construction efficiency, and achieve improved construction efficiency, easy temperature control, and low hydration temperature rise. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

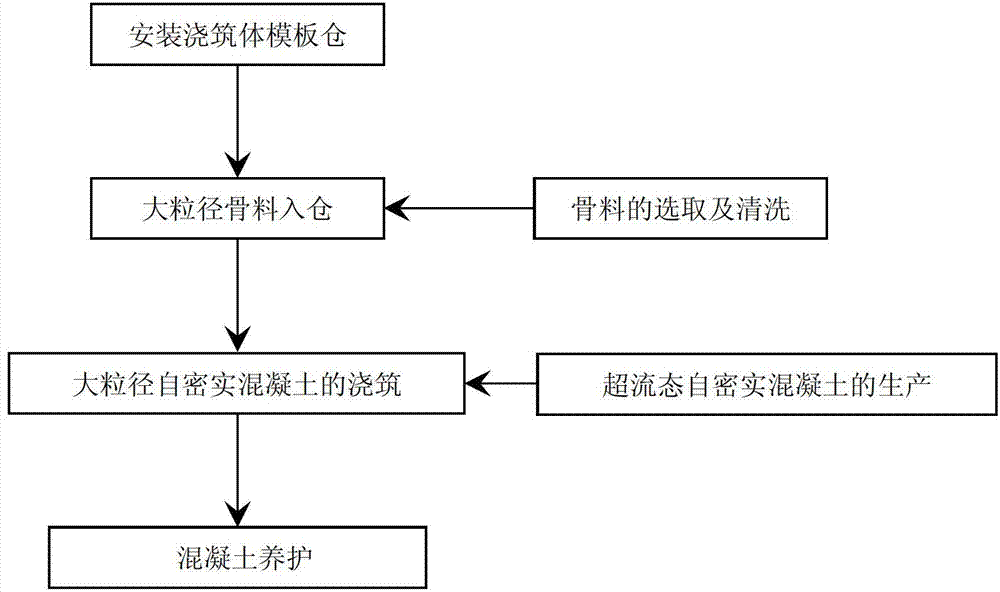

Method used

Image

Examples

Embodiment 1-3

[0043] Example 1-3: Preparation of superfluid self-compacting concrete with different fly ash content

[0044] Table 1 Proportion of superfluid self-compacting concrete (by weight, the same below)

[0045]

[0046]

[0047] The properties of the prepared superfluid self-compacting concrete are shown in Table 2:

[0048] Table 2 Properties of superfluid self-compacting concrete with different amounts of fly ash

[0049]

[0050] It shows that the change of large amount of fly ash has a significant effect on the workability of concrete, and also has a great effect on the early strength of concrete, but has little effect on the 28d strength. Choosing an appropriate amount of fly ash has a positive effect on the workability and strength of superfluid self-compacting concrete, and facilitates the construction of self-compacting concrete with ultra-large particle size aggregates.

Embodiment 4-6

[0051] Example 4-6: Preparation of superfluid self-compacting mortars with different water-binder ratios

[0052] The cement is Portland cement with a strength grade of 42.5 produced by Guizhou Cement Factory;

[0053] The fly ash is the first-class fly ash produced by Guizhou Power Plant;

[0054] The superfluid special admixture is selected from the superfluid self-compacting concrete admixture (composed of polycarboxylate superplasticizer, sodium gluconate, cellulose ether and sodium dodecylbenzenesulfonate in a mass ratio of 75:4.5: 20:0.5 composite, the polycarboxylate superplasticizer has a solid content of 29wt%);

[0055] The sand is selected from river sand with a particle size not greater than 5mm.

[0056] The stones are crushed stones with continuous gradation of 5-10mm, the content of needle-like particles is less than 10wt%, and the porosity is less than 40%.

[0057] Table 3 Proportion of superfluid self-compacting mortar (by weight)

[0058]

[0059]

...

Embodiment 7

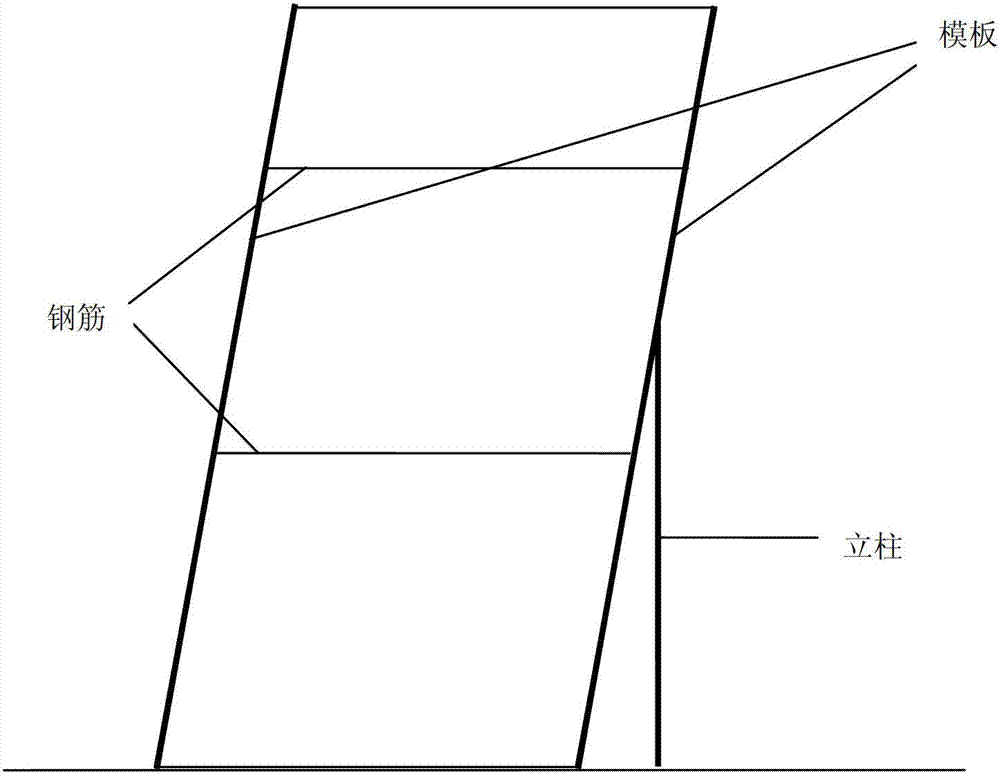

[0064] Example 7: Construction method of gravity retaining wall for highway

[0065] The gravity retaining wall maintains the stability of the retaining wall under the earth pressure by the self-weight of the wall. It is the most commonly used form of retaining wall in my country at present. The design strength of the retaining wall in this case is 30MPa.

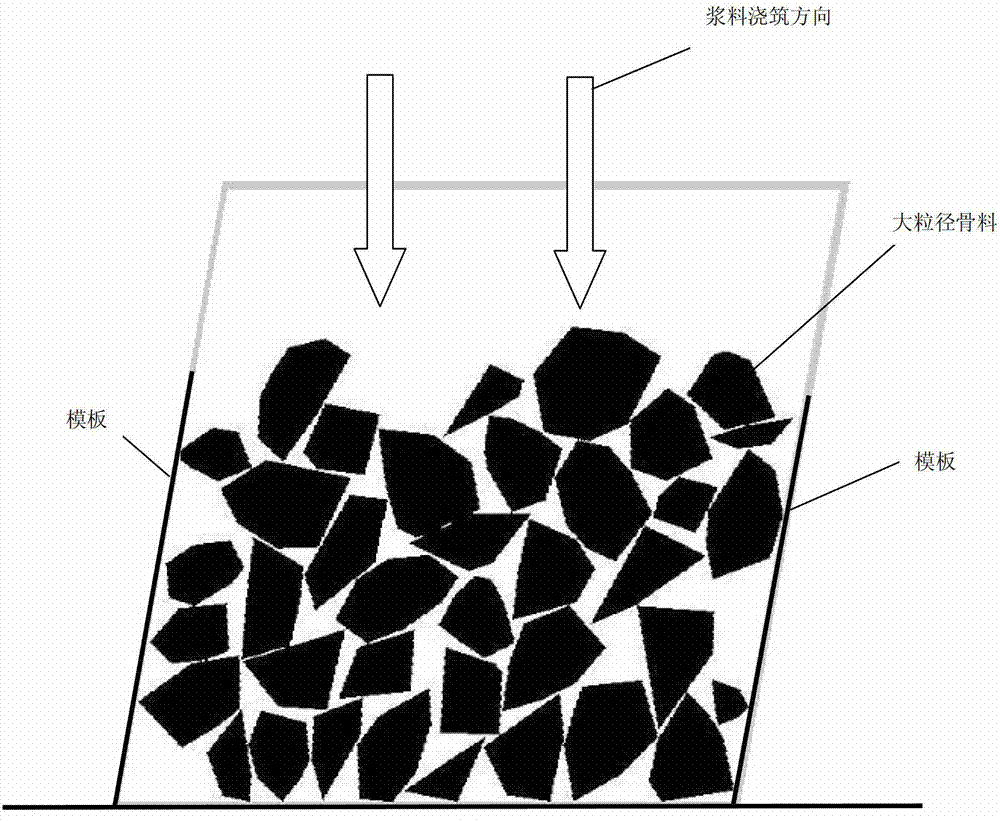

[0066] Ingredients: large-size aggregates are selected from limestone or marble, the particle size is controlled at 300-1500mm, no weathering, integrity, hard texture, no peeling layer and cracks, no mud layer on the surface, and the content of mud and mud blocks is not more than 0.5 wt%, the saturated water compressive strength is not less than 30MPa, and the batching type selection of preparing superfluid self-compacting concrete is the same as embodiment 1;

[0067] Batching ratio of superfluid self-compacting concrete: (by weight)

[0068]

[0069] Construction methods:

[0070] (1) In addition to using traditiona...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Strength | aaaaa | aaaaa |

| Slump | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com