Method for preparing active carbon from lotus seed hulls

A technology for preparing activated carbon and lotus seed shells, applied in chemical instruments and methods, inorganic chemistry, non-metallic elements, etc., can solve problems such as pollution, achieve the effects of reducing manufacturing costs, sufficient sources, and solving environmental pollution problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment example 1

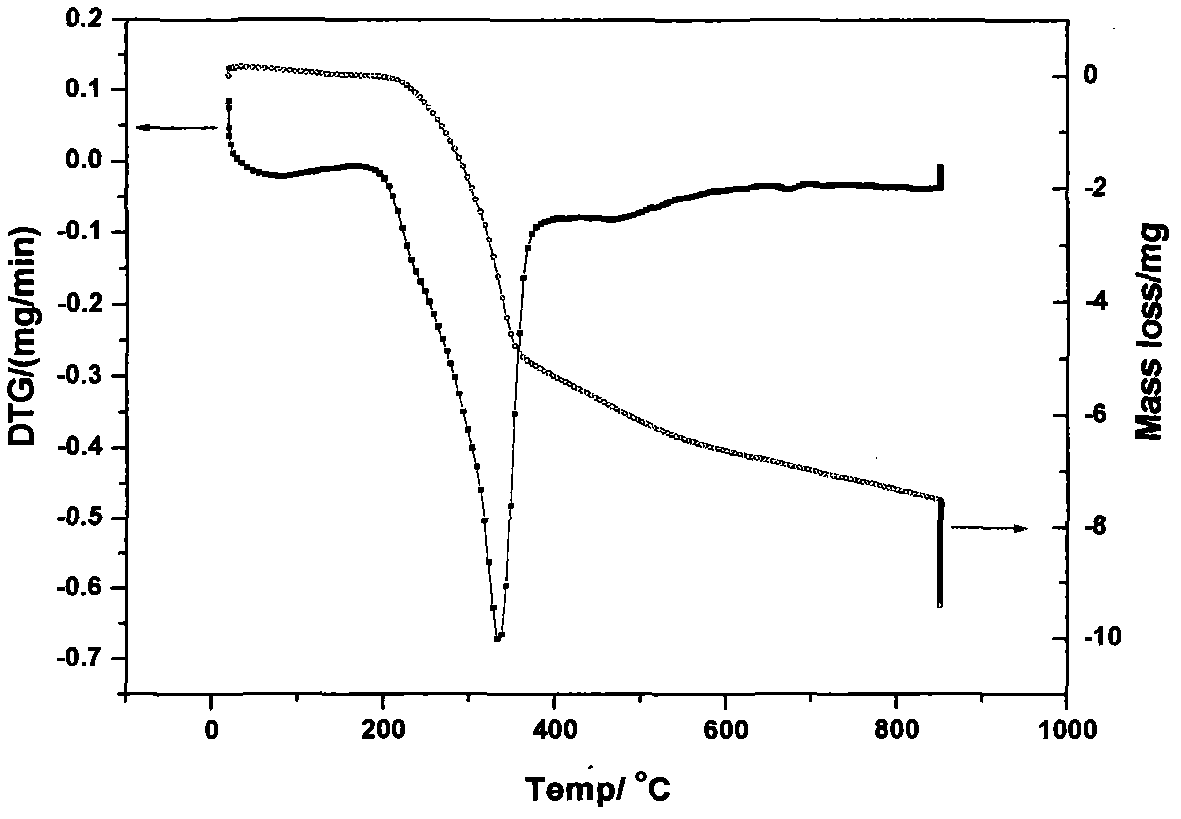

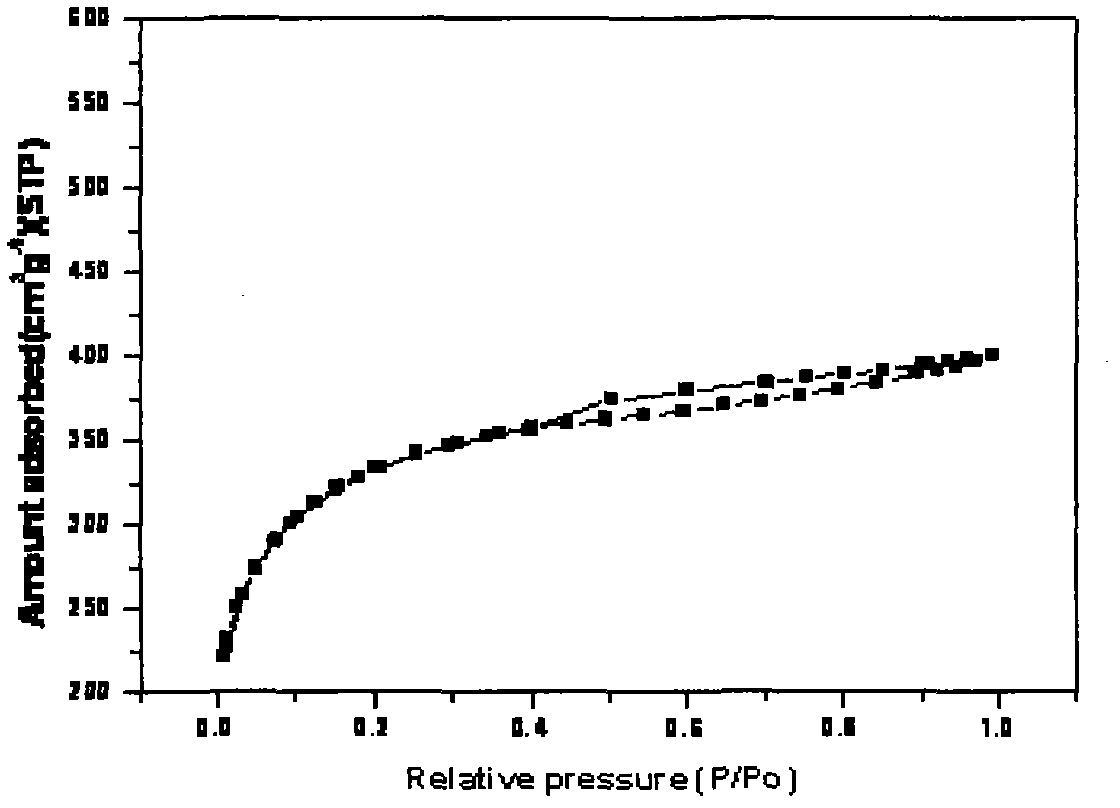

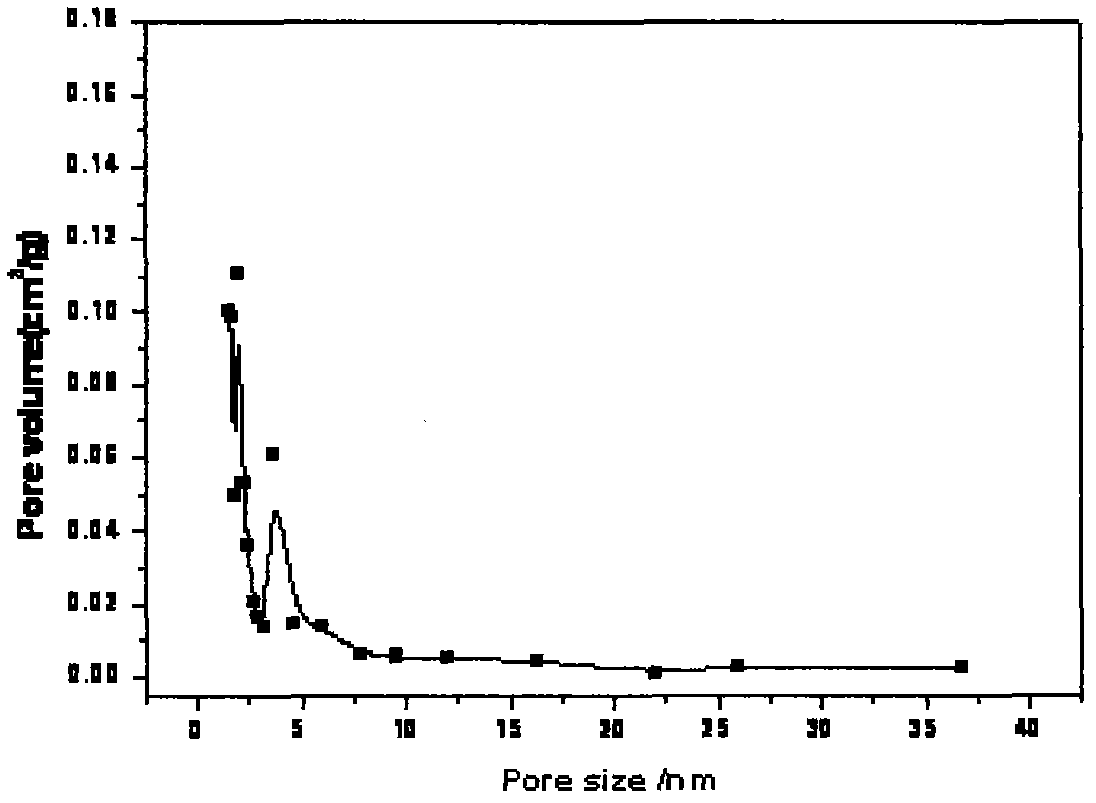

[0024] Use lotus seed shells that have been removed from sand and stones, dried, and crushed to a particle size of 5 mm as raw material, zinc chloride is used as an activator, and the mass ratio of lotus seed shells: activators is 1: (1.5-2.5) Mix, add 90 Stir and impregnate ~130mL water for 8~10h, moisten and puff, then dry. The rate is 3-5°C / min, heated to 650-750°C and activated for 30-60 minutes, cooled naturally, washed with 1-2mol / L hydrochloric acid and distilled water until the pH of the filtrate=6-7, and dried to obtain Uniform, strong, unbreakable granular lotus seed shell-based activated carbon. The test result characteristic curve is as follows figure 1 , 2 , 3, 4 shown.

Embodiment example 2

[0026] Use lotus seed shells that have been removed from sand and stones, dried, and crushed to a particle size of 5 mm as raw material, zinc chloride is used as an activator, and the mass ratio of lotus seed shells: activators is 1: (2.8~3.5) Mix, add 130 ~160mL water is stirred and impregnated for 10~12h, moistened and puffed, then dried. Under the protection of inert gas, the heating rate is 5~10°C / min. The rate is 4-6°C / min, heated to 750-850°C and activated for 60-90 minutes, cooled naturally, washed with 1-2mol / L hydrochloric acid and distilled water until the pH of the filtrate = 6-7, and dried to obtain Uniform, strong, unbreakable granular lotus seed shell-based activated carbon. The test result characteristic curve is as follows figure 1 , 5 , 6, and 7.

[0027] The characteristic parameters of lotus seed shell-based activated carbon prepared in different implementation cases are as follows

[0028]

[0029] a S BET , BET specific surface area; S mic , micr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com