Sea sand powder concrete

A technology for powder concrete and sea sand, which is applied in the field of concrete materials, can solve the problems of low production efficiency, high cost, and is not suitable for large-scale production of sea sand concrete, and achieves the effect of promoting hydration reaction and reducing water consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

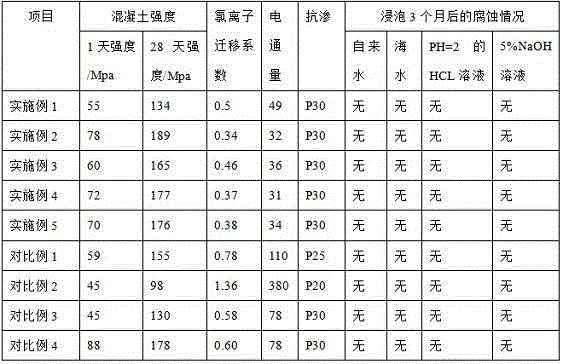

Examples

Embodiment 1

[0048]A self-compacting sea-sand concrete, comprising the following raw materials in parts by weight:

[0049] 450 parts of ordinary Portland cement;

[0050] Mineral active admixture; 250 parts;

[0051] 50 parts of inert admixture;

[0052] 850 parts of sea sand;

[0053] 24 parts of early strength superplasticizer;

[0054] 145 parts of sea water;

[0055] 2 parts organic fiber;

[0056] 0.08mm~0.35mm copper-plated steel fiber 78 parts.

[0057] Among them, the average particle size of the cement is less than 60 μm, and the grade is not lower than 42.5 grade strength; the particle size range of the mineral active admixture is 0.10~60 μm; the average particle size of the inert admixture is 0.01~80 μm The average particle size of the sea sand is below 4.75mm, the particles are continuously graded medium sand and fine sand, and the mud content is less than 0.5%; the organic fiber is a PVA fiber with a high-strength elastic modulus, and its length is 6-12mm; The tensile ...

Embodiment 2

[0064] Except that the formula of sea sand powder concrete and the formula of inert admixture and mineral active admixture are different, other conditions are the same as embodiment 1;

[0065] A self-compacting sea-sand concrete, comprising the following raw materials in parts by weight:

[0066] 750 parts of ordinary Portland cement;

[0067] 450 parts of mineral active admixture;

[0068] 150 parts of inert admixture;

[0069] 1400 parts of sea sand;

[0070] 32 parts of early strength superplasticizer;

[0071] 220 parts of sea water;

[0072] 4 parts organic fiber;

[0073] 0.08mm~0.35mm copper-plated steel fiber 250 parts.

[0074] Wherein, the mineral active admixture includes the following raw materials by weight: 20% silica fume, 30% mineral powder, 25% fly ash, 20% ceramic polishing powder, and 5% steel slag; the inert admixture includes the following weight Percentage of raw materials: limestone powder 10%, nano calcium carbonate 80%, quartz stone powder 10%....

Embodiment 3

[0076] Except that the formula of sea sand powder concrete is different, other conditions are with embodiment 1;

[0077] A self-compacting sea-sand concrete, comprising the following raw materials in parts by weight:

[0078] 550 parts of ordinary Portland cement;

[0079] 330 parts of mineral active admixture;

[0080] 80 parts of inert admixture

[0081] 950 parts of sea sand;

[0082] 26 parts of early-strength superplasticizer;

[0083] 165 parts of sea water;

[0084] 2 parts organic fiber;

[0085] 0.08mm~0.35mm copper-plated steel fiber 100 parts.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com