Polylactic acid-based composite material surgical medical film and preparation method thereof

A composite material and polylactic acid-based technology, which is applied in the field of medical supplies, can solve problems such as patents that have not been reported, and achieve the effects of preventing wound healing, good controllable degradation behavior, and good tissue compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

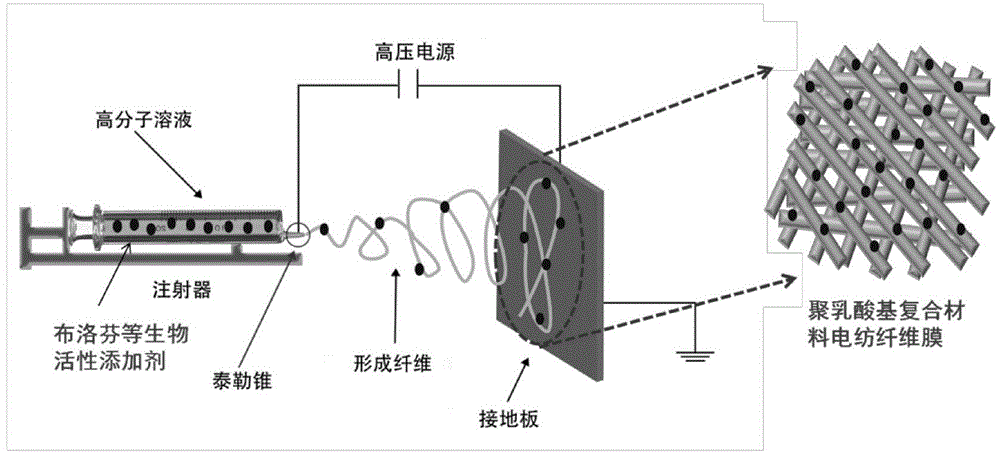

[0028] (1) Preparation of polymer electrospinning solution: the polylactic acid / ibuprofen composite material was dissolved in dichloromethane, and magnetically stirred for 24 hours to obtain a uniform solution system. The concentration of polymer solution is 10% (by mass fraction);

[0029] (2) Electrospinning: The polymer solution obtained in (1) is placed in the feeding syringe of the electrospinning equipment, the feeding speed of the solution is 0.5mm / min, and the ambient temperature of spinning is set to 30°C. Turn on the high-voltage power supply and adjust the voltage to 15kV, the distance between the needle tip of the syringe and the static ground plate is 15cm, and finally the electrospun fiber film is obtained on the static ground plate;

[0030] (3) Collect the fibrous film on the static ground plate and place it in an oven to dry to remove the organic solvent. The oven temperature is set at 40° C., and the drying time is 12 hours until the organic solvent weight co...

Embodiment 2

[0033] (1) Preparation of polymer electrospinning solution: Dissolve polylactic acid / hyaluronic acid composite material in dichloromethane, and magnetically stir for 6-48 hours to obtain a uniform solution system. The concentration of the polymer solution is 5-20% (by mass fraction);

[0034](2) Electrospinning: The polymer solution obtained in (1) is placed in the feeding syringe of the electrospinning equipment, the feeding speed of the solution is 0.5mm / min, and the ambient temperature of spinning is set to 30°C. Turn on the high-voltage power supply and adjust the voltage to 15kV, the distance between the needle tip of the syringe and the static ground plate is 15cm, and finally the electrospun fiber film is obtained on the static ground plate;

[0035] (3) Collect the fibrous film on the static ground plate and place it in an oven to dry to remove the organic solvent. The oven temperature is set at 40° C., and the drying time is 12 hours until the organic solvent weight c...

Embodiment 3

[0038] (1) Preparation of polymer electrospinning solution: dissolve the polylactic acid / antibiotic composite material in dichloromethane, and stir magnetically for 6-48 hours to obtain a uniform solution system. The concentration of the polymer solution is 5-20% (by mass fraction);

[0039] (2) Electrospinning: The polymer solution obtained in (1) is placed in the feeding syringe of the electrospinning equipment, the feeding speed of the solution is 0.5mm / min, and the ambient temperature of spinning is set to 30°C. Turn on the high-voltage power supply and adjust the voltage to 15kV, the distance between the needle tip of the syringe and the static ground plate is 15cm, and finally the electrospun fiber film is obtained on the static ground plate;

[0040] (3) Collect the fibrous film on the static ground plate and place it in an oven to dry to remove the organic solvent. The oven temperature is set at 40° C., and the drying time is 12 hours until the organic solvent weight c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com