Oily sewage purification net membrane and preparation method and application thereof

A technology for sewage purification and oily sewage, applied in chemical instruments and methods, separation methods, water/sewage treatment, etc., can solve the problems of long degradation time and low treatment efficiency, and achieve high separation efficiency, simple equipment and production process. , the effect of reducing chemical oxygen consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

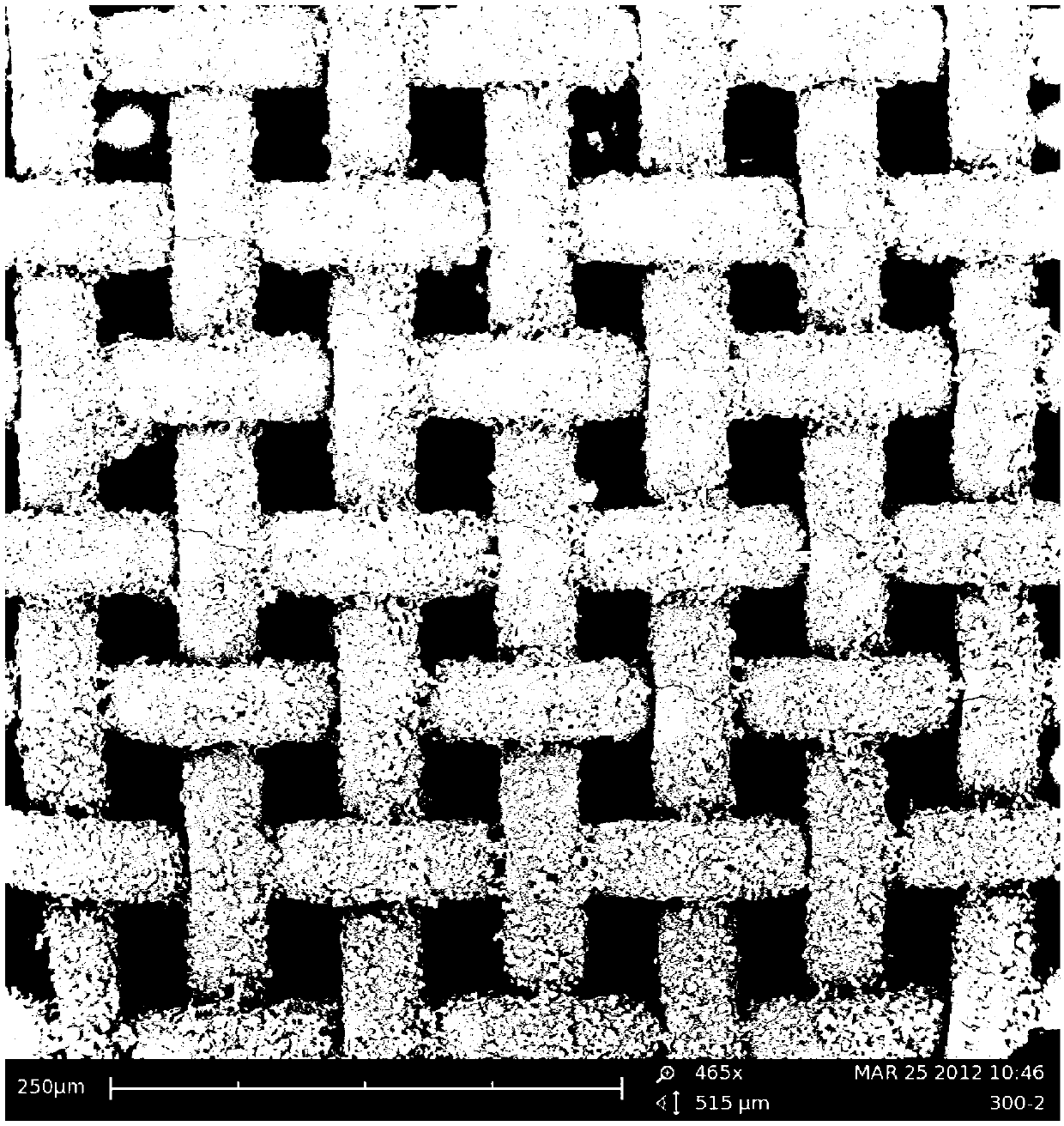

[0037] Example 1, preparation of oily sewage purification omentum with superhydrophobic and superoleophilic properties

[0038] (1) Dip the 300-mesh copper mesh (i.e. copper fiber fabric mesh) into ethanol and acetone for ultrasonic cleaning for 5 minutes, and dry at room temperature;

[0039] (2) At room temperature, add 4ml of TiCl with a mass fraction of 20% in a 100ml beaker 3 solution and 36ml deionized water, mixed with stirring to obtain 0.15M TiCl 3 solution, and then add 15g NaCl to the solution to make the solution saturated with NaCl.

[0040] (3) Add the mixed solution obtained in step 2 into a 45ml Teflon reactor, and immerse the copper grid treated in step 1 into the solution in the Teflon reactor, and then heat the reactor at 160°C for 2 hours.

[0041] (4) After taking out the copper mesh in the reaction kettle of step 3, wash it with deionized water and ethanol, then dry it at room temperature to obtain TiO 2 Covered copper mesh.

[0042] (5) At room tempera...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com