Preprocessing method of hexadecyl trimethyl ammonium bromide for molasses alcohol waste water

A technology of cetyltrimethylammonium bromide and molasses alcohol wastewater, which is applied in the direction of food industry wastewater treatment, chemical instruments and methods, water/sewage multi-stage treatment, etc., to achieve chromaticity reduction, load reduction, and adaptability strong effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

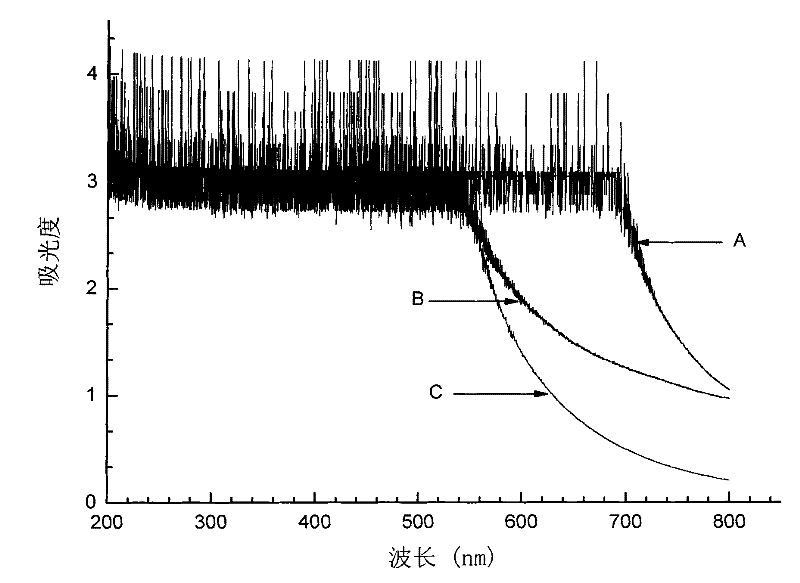

[0013] Taking the pretreatment of 1000mL molasses alcohol wastewater as an example, the raw materials used and the pretreatment method are as follows:

[0014] Get molasses alcohol wastewater 1000mL, add mass fraction and be 50mL of cetyltrimethylammonium bromide aqueous solution of 20%, namely molasses alcohol wastewater and massfraction are the cetyltrimethylammonium bromide aqueous solution volume ratio of 20% 1:0.05, stir, mix evenly, let stand for 1 to 5 minutes, centrifuge at 4000 rpm for 20 minutes in a high-speed centrifuge, precipitate, separate the precipitate, and the supernatant enters the biochemical system for processing.

Embodiment 2

[0016] Taking the pretreatment of 1000mL molasses alcohol wastewater as an example, the raw materials used and the pretreatment method are as follows:

[0017] Take 1000mL of molasses alcohol wastewater, add 15mL of cetyltrimethylammonium bromide aqueous solution with a mass fraction of 20%, that is, the volume of molasses alcohol wastewater and 20% cetyltrimethylammonium bromide aqueous solution The ratio is 1:0.015, stirring, mixing evenly, standing still for 1 to 5 minutes, centrifuging at 4000 rpm for 20 minutes in a high-speed centrifuge, settling, separating the precipitate, and the supernatant enters the biochemical system for processing.

Embodiment 3

[0019] Taking the pretreatment of 1000mL molasses alcohol wastewater as an example, the raw materials used and the pretreatment method are as follows:

[0020] Get 1000mL of molasses alcohol wastewater, add 60mL of cetyltrimethylammonium bromide aqueous solution with a mass fraction of 20%, that is, the volume ratio of molasses alcohol wastewater to 20% cetyltrimethylammonium bromide aqueous solution 1:0.06, stir, mix evenly, let stand for 1 to 5 minutes, centrifuge at 4000 rpm for 20 minutes in a high-speed centrifuge, precipitate, separate the precipitate, and the supernatant enters the biochemical system for processing.

PUM

| Property | Measurement | Unit |

|---|---|---|

| decolorization rate | aaaaa | aaaaa |

| clearance rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com