Silicon-free softening agent and preparation method thereof

A softener and catalyst technology, applied in the field of silicon-free softener and its preparation, can solve the problems of non-hydrophilic, poor bulkiness, insufficient skin-friendly, etc., and achieve the effects of reducing biodegradation, improving properties, and feeling fluffy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

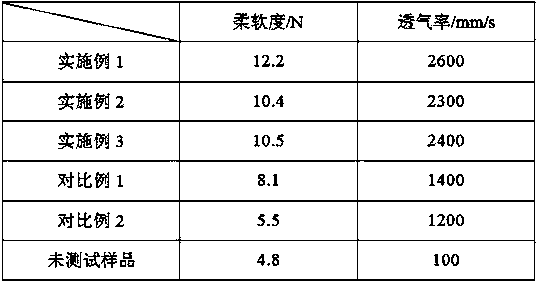

Examples

Embodiment 1

[0030] A non-silicon softener, the non-silicon softener is made up of the following parts by weight: 50 parts of tallow, 15 parts of stearic acid, 10 parts of diethylenetriamine, 8 parts of diethyl sulfate, 7 parts of isopropanol , 5 parts of modified polyvinyl alcohol, 3 parts of sodium lauryl sulfate.

[0031] The modified polyvinyl alcohol consists of the following materials in parts by weight: 30 parts of polyvinyl alcohol, 1 part of catalyst, 40 parts of deionized water, 3 parts of trimethylolpropane, 25 parts of butyl acrylate, and 0.6 part of calcium carbonate.

[0032] The catalyst is organic zinc.

[0033] The preparation method of the modified polyvinyl alcohol is as follows: heat polyvinyl alcohol, water, and trimethylolpropane to 95°C until they are completely dissolved, add butyl acrylate and a catalyst for graft copolymerization, cool down to 50°C, and then add Calcium carbonate, stirred evenly, centrifuged to get solid matter, finally dried, pulverized and grou...

Embodiment 2

[0042] The difference between embodiment 2 and embodiment 1 is that the proportion of the non-silicon softener is different, and the others are the same.

[0043] A non-silicon softener, the non-silicon softener is made up of the following parts by weight: 40 parts of tallow, 20 parts of stearic acid, 6 parts of diethylenetriamine, 10 parts of diethyl sulfate, 4 parts of isopropanol , 7 parts of modified polyvinyl alcohol, 5 parts of sodium lauryl sulfate.

Embodiment 3

[0045] Embodiment 3 differs from Embodiment 1 in that the proportion of the non-silicon softener is different, and the others are the same.

[0046] A non-silicon softener, the non-silicon softener is made up of the following parts by weight: 60 parts of tallow, 10 parts of stearic acid, 14 parts of diethylenetriamine, 6 parts of diethyl sulfate, 10 parts of isopropanol , 3 parts of modified polyvinyl alcohol, 1 part of sodium lauryl sulfate.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com