Composite papermaking pulp substrate and its preparation method

A substrate and pulp-making technology, which is applied in the field of pulp-based pulp and pulp-making, can solve the problems of product properties, textures, application differences, etc., and achieve the goals of reducing chemical oxygen consumption, good smoothness, and enhanced uniformity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

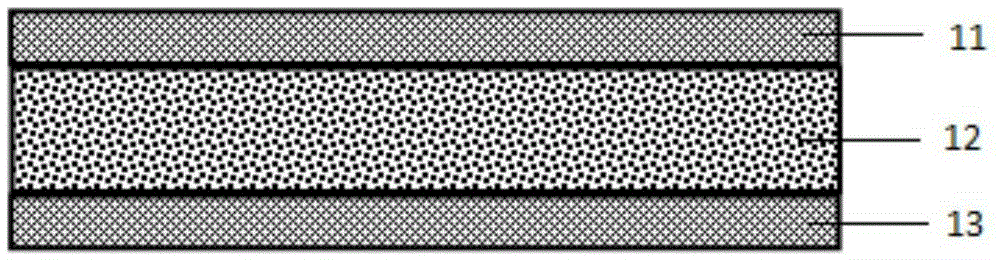

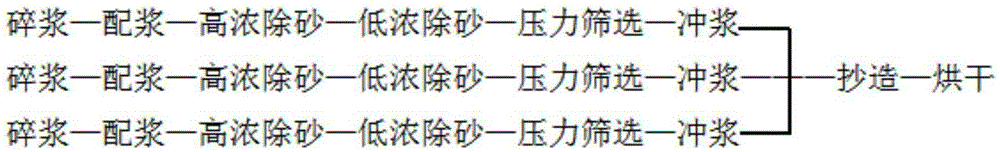

[0057] A kind of composite papermaking pulp substrate, this substrate comprises surface layer, core layer and bottom layer, and the mass ratio of above-mentioned three layers is 3.02: 2.12: 1.21; The raw material that described surface layer adopts is bamboo fiber, sugarcane pulp fiber and Powdered activated carbon, the mass ratio of the above three raw materials in the surface layer is 7.65: 5.14: 1.25, wherein the average fiber diameter of bamboo fiber is 29 microns, and the average fiber length is 0.5 mm, sugarcane husk pulp fiber and The mass ratio of sugarcane core pulp fiber is 2.83:4.85, the mass ratio of shell activated carbon and coal-based activated carbon in powdered activated carbon is 6.54:4.56, the average particle size range of powdered activated carbon is 98 microns, and the largest particle and the smallest particle Particle size ratio160 micron is 4.51: 1.26; described bottom layer raw material is bamboo fiber, ramie pulp fiber and sugarcane pulp fiber, and t...

Embodiment 2

[0069] A composite papermaking pulp base sheet, the base sheet includes a surface layer, a core layer and a bottom layer, the mass ratio of the above three layers is 6.85:6.63:2.23; the raw materials used for the surface layer are bamboo fiber, sugarcane pulp fiber and Powdered activated carbon, the mass ratio of the above three raw materials in the surface layer is 8.91: 7.23: 1.91, wherein the average fiber diameter of bamboo fiber is 46 microns, and the average fiber length is 7.6 mm, sugarcane husk pulp fiber and The mass ratio of sugarcane core pulp fiber is 3.66:6.76, the mass ratio of shell activated carbon and coal-based activated carbon in powdered activated carbon is 8.35:5.87, the average particle size of powdered activated carbon is 126 microns, and the particle size of the largest particle and the smallest particle is Diameter ratio160 microns is 5.23:6.12 The bottom raw material is bamboo fiber, ramie pulp fiber and sugarcane pulp fiber, and the mass ratio of the...

Embodiment 3

[0072] A composite papermaking pulp base sheet, the base sheet includes a surface layer, a core layer and a bottom layer, the mass ratio of the above three layers is 4.76: 3.95: 2.01; the raw materials used in the surface layer are bamboo fiber, sugarcane pulp fiber and Powdered activated carbon, the mass ratio of the above three raw materials in the surface layer is 8.02:6.25:1.46, wherein the average fiber diameter range of bamboo fiber is 32 microns, the average fiber length is 5.6 mm, and the sugarcane husk pulp fiber in the sugarcane pulp fiber The mass ratio of sugarcane core pulp fiber is 3.22:5.37, the mass ratio of shell activated carbon and coal-based activated carbon in powdered activated carbon is 7.36:5.43, the average particle size range of powdered activated carbon is 116 microns, and the largest particle and the smallest particle The particle diameter ratio160 microns is 5.02 : 6.06; the raw material of the bottom layer is bamboo fiber, ramie pulp fiber and sug...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com