Method for preparing gold magnetic particles

A technology of gold magnetic particles and particles, which is applied in the field of composite material synthesis, can solve the problems of non-adoption and achieve the effects of less agglomeration, mild reaction conditions and convenient application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] A kind of forward microemulsion each reagent and its proportioning ratio are as follows:

[0042] components

Reagent name

Amount of reagent

1. Oil phase

Toluene containing 0.5g oxide particles

20ml

2. Water phase

Containing 10% chloroauric acid deionized aqueous solution

200ml

3. Surfactant

Dodecyltrimethylammonium Chloride

0.5g

1M Hydroxylamine Hydrochloride

10ml

[0043] Specific steps are as follows:

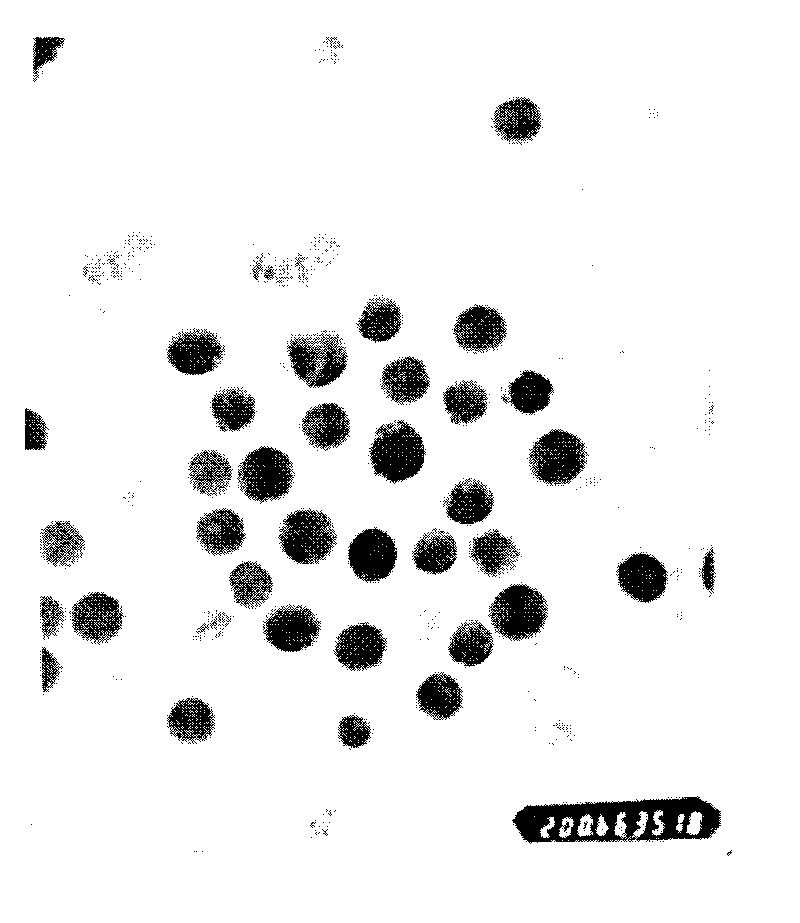

[0044] Stir and mix component 1 and component 3 in the above table for 10 minutes, then add component 2 and continue to react for 40 minutes to form a microemulsion, then add component 4 dropwise, react for 5 hours, add 200ml of ethanol and stir for 5 minutes For demulsification, place the reactants on a magnet for magnetic separation, discard the supernatant, and wash with water for 3 times to obtain gold magnetic particles with a particle size of about 60 nm.

Embodiment 2

[0046] A kind of forward microemulsion each reagent and its proportioning ratio are as follows:

[0047] components

Reagent name

Amount of reagent

1. Oil phase

Cyclohexane with 0.5 g of oxide particles

20ml

2. Water phase

Containing 10% chloroauric acid deionized aqueous solution

200ml

[0048] components

Reagent name

Amount of reagent

3. Surfactant

Octadecyl dimethyl benzyl ammonium chloride

0.5g

1M Hydroxylamine Hydrochloride

10ml

5. Co-surfactant

n-pentyl mercaptan

3ml

[0049] Specific steps are as follows:

[0050] Stir and mix component 1 and component 3 in the above table for 5 minutes, then add component 5 and continue stirring for 5 minutes, then add component 2 and continue to react for 40 minutes to form a microemulsion, then add component 4 drop by drop, and react After 5 hours, add 200ml of ethanol and stir for 5 minute...

Embodiment 3

[0052] A kind of forward microemulsion each reagent and its proportioning ratio are as follows:

[0053]

[0054] Specific steps are as follows:

[0055]Configure the reagents of each component as listed in the above table, stir to form a microemulsion, add microemulsion II to microemulsion I under stirring conditions, and react for 40 minutes, then add microemulsion III dropwise to the above reaction under stirring conditions During the reaction, the reaction was continued for 4 hours. After the reaction was completed, ethanol was added to break the emulsion, the supernatant was discarded by magnetic separation, and then washed with water to obtain gold magnetic particles.

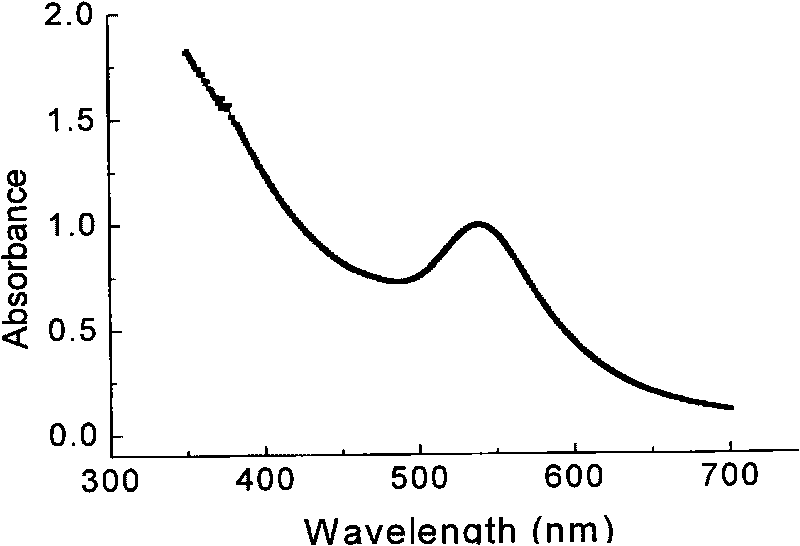

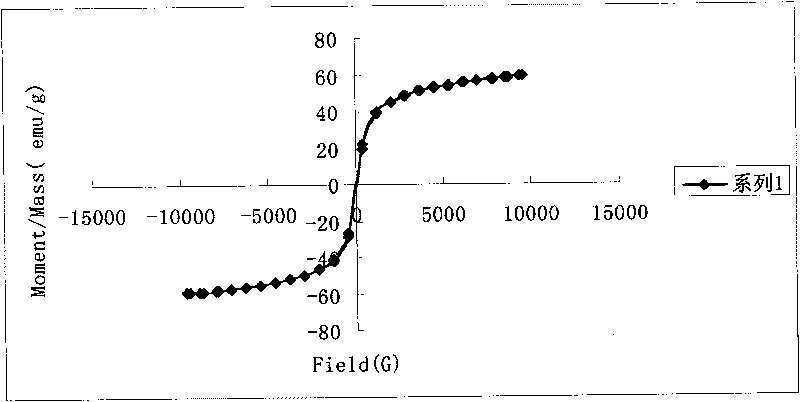

[0056] As can be seen from the above examples, the method for preparing gold magnetic particles has mild reaction conditions, simple preparation process, no need for large-scale equipment, and the prepared gold magnetic particles have good dispersibility and uniform particle size. photos such as figu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com