Electromagnetic integrated nanofiber filter material and preparation and activation method thereof

A nanofiber and activation method technology, applied in the direction of fiber chemical characteristics, fiber type, fiber treatment, etc., can solve the problems of not mentioning the activation time and activation rate of electrets, the immature and unexplained synthesis process of charge-enhancing additives, etc. , to enhance the interface polarization effect, enhance the ability to store charges for a long time, and reduce the direct current loss.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049] The preparation and rapid activation method of an electromagnetic integrated nanofiber filter material in this embodiment, the specific steps are:

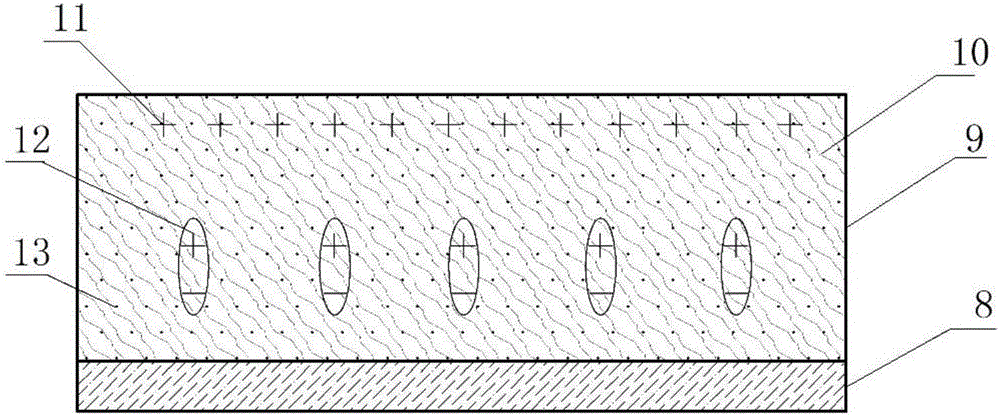

[0050](1) Dry polyvinyl chloride (PVC) powder in a vacuum oven at 60° C. for 2 hours. Accurately weigh 10.9875g N-N dimethylformamide and 10.9875g tetrahydrofuran with an electronic balance and place it in a 50mL beaker, then weigh 0.0250g nanometer magnetic iron oxide (purity 99.5%, average particle diameter 15nm) and place it in the above mixed solvent, Vibrate with an ultrasonic oscillator for 1.5 hours, take out the beaker, accurately weigh 3g of dry polyvinyl chloride powder with an electronic balance, and place it in the beaker. Polyvinyl chloride spinning solution containing magnetic iron oxide nanoparticles.

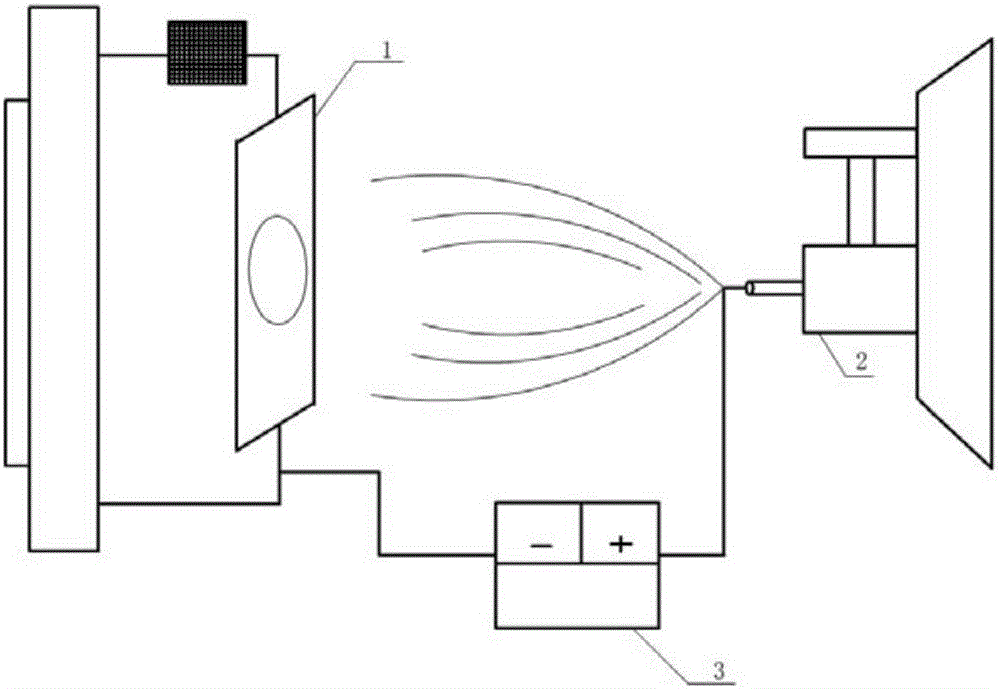

[0051] (2) use figure 1 The electrospinning equipment shown in the figure performs electrospinning, sticks the cut substrate on the flat receiver, adjusts the electrospinning parameters, the translational sp...

Embodiment 2

[0055] The preparation and rapid activation method of an electromagnetic integrated nanofiber filter material in this embodiment, the specific steps are:

[0056] (1) Dry the chlorinated polyvinyl chloride powder in a vacuum oven at 60° C. for 2 hours. Accurately weigh 10.9875g N-N dimethylformamide and 10.9875g tetrahydrofuran with an electronic balance and place it in a 50mL beaker, then weigh 0.025g nanometer magnetic cobalt oxide (purity 99%, average particle diameter 20nm) and place it in the above mixed solvent, Vibrate with an ultrasonic oscillator for 2 hours, take out the beaker, accurately weigh 3g of dry chlorinated polyvinyl chloride powder with an electronic balance, and place it in the beaker. Chlorinated polyvinyl chloride spinning solution containing magnetic cobalt oxide nanoparticles.

[0057] (2) use figure 1 The electrospinning equipment shown in the figure performs electrospinning, sticks the cut substrate on the flat receiver, adjusts the electrospinnin...

Embodiment 3

[0061] The preparation and rapid activation method of an electromagnetic integrated nanofiber filter material in this embodiment, the specific steps are:

[0062] (1) Dry the polyvinylidene fluoride powder in a vacuum oven at 60° C. for 2 hours. Accurately weigh 21.975g of N-N dimethylformamide with an electronic balance and place it in a 50mL beaker, then weigh 0.025g of nano-magnetic iron oxide (purity 99.5%, average particle size 15nm) and place it in the above solvent, and shake it with an ultrasonic oscillator 1.5h, take out the beaker, accurately weigh 3g of dry polyvinylidene fluoride powder with an electronic balance and place it in the beaker, place the beaker in a water bath constant temperature oscillator for 6 hours, and prepare a uniform and stable magnetic iron oxide at a constant temperature of 40°C Nanoparticles of polyvinylidene fluoride spinning solution.

[0063] (2) use figure 1 The electrospinning equipment shown in the figure performs electrospinning, s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com