Soft magnetic composite material and preparation method thereof

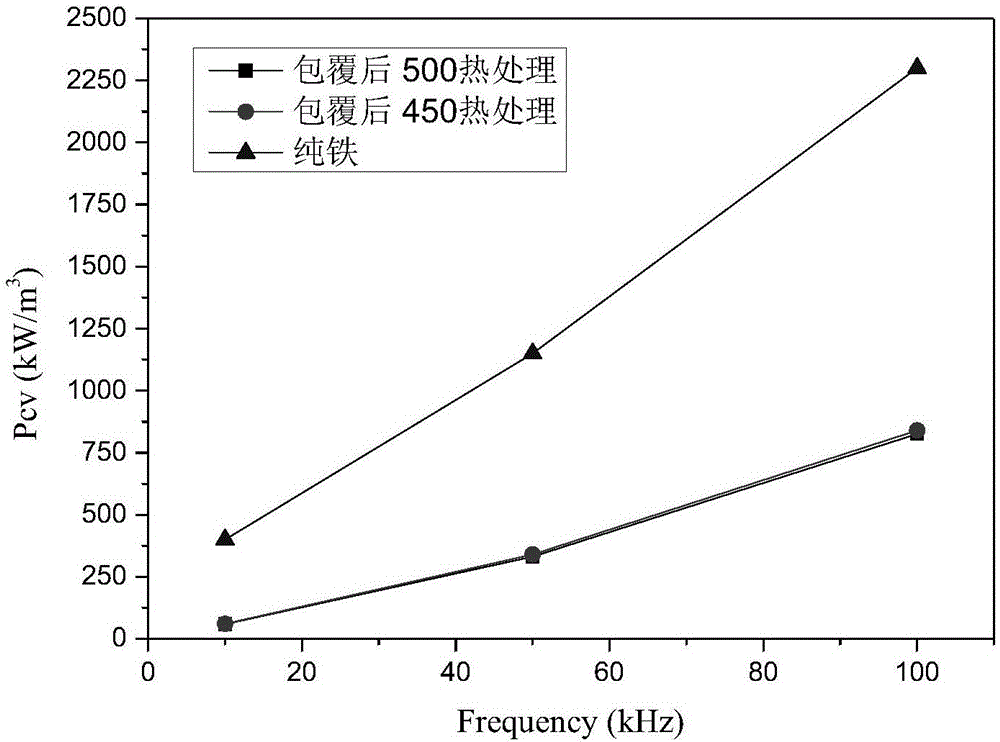

A soft magnetic composite material, iron powder technology, applied in the direction of magnetic material, inorganic material magnetism, magnetic object, etc., can solve the problem that the composite material of the organic insulating layer cannot work at high temperature, cannot be subjected to high heat treatment, and the saturation magnetic induction intensity is reduced. and other problems, to achieve the effect of small magnetic performance, high production efficiency, and reduced eddy current loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

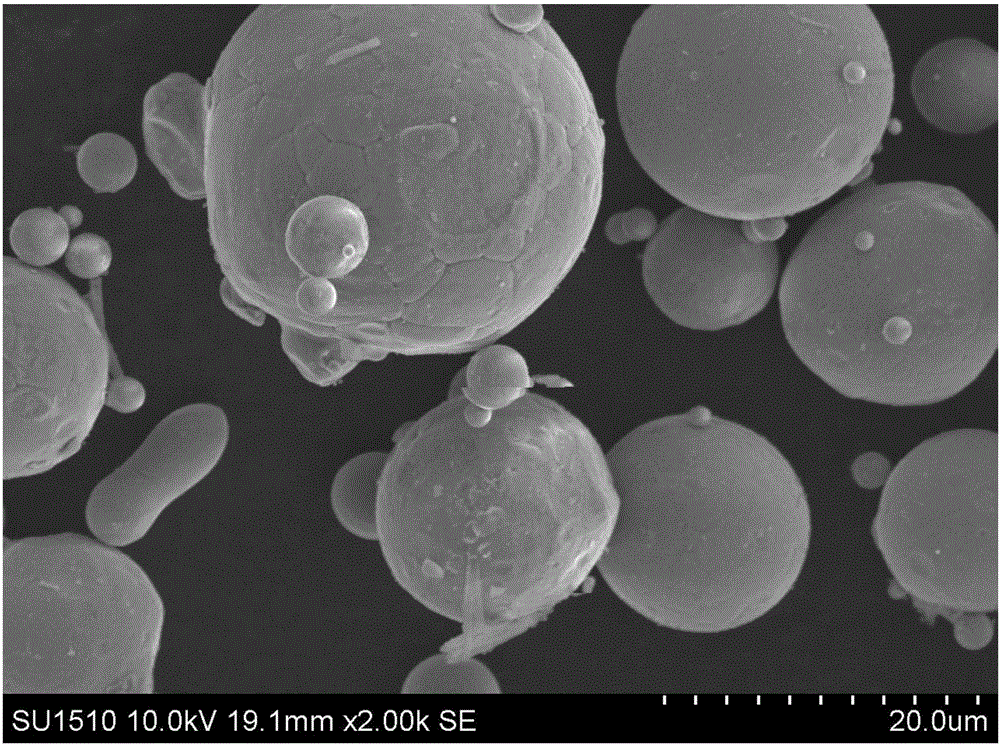

[0025] Put 21g of pure iron powder (particle size 75μm) in 0.5% dilute hydrochloric acid aqueous solution for pickling for 30min, wash the residual liquid on the surface of iron powder with cold water, and obtain 20g of pure iron powder after cleaning; weigh 60g of NaOH dissolved in 400ml of distilled water In, weigh 60gNaNO 2 and 20gK 2 Cr 2 o 7 Dissolve in 40ml of distilled water, pour the mixture of the two into a three-necked flask and heat to boiling, add 20g of cleaned pure iron powder and stir for 180min; leave to cool, filter, and filter the cake in turn with cold water, hot water and absolute ethanol respectively Wash 3 times; put the sample into a vacuum oven and dry at 50°C for 6 hours to obtain 20g of pretreated pure iron powder; mix 20g of pretreated pure iron powder with 0.1g of epoxy resin (model W-6C), 5ml Acetone is mixed and dissolved, after ultrasonic dispersion, it is air-dried in a ventilated place to remove acetone, and then pressed into a ring (18mm O...

Embodiment 2

[0027] Put 21g of pure iron powder (150 μm in particle size) in 1% dilute hydrochloric acid aqueous solution for 15 minutes, wash the residual liquid on the surface of pure iron powder with cold water, and obtain 20 g of pure iron powder after cleaning; weigh 80 g of NaOH and dissolve it in 400 ml of In distilled water, weigh 40g K 4 Fe(CN) 6 Dissolve in 40ml of distilled water, pour the mixture of the two into a three-necked flask and heat to boiling, add 20g of cleaned pure iron powder and stir for 10min; leave to cool, filter, and wash the filter cake in turn with cold water, hot water and absolute ethanol 3 times; put the sample into a vacuum drying oven at 100 ° C for 1 hour to obtain 20 g of pretreated pure iron powder; mix 20 g of pretreated pure iron powder with 0.1 g of epoxy resin (type W-6C), 5 ml of acetone Mix and dissolve, ultrasonically disperse, then air-dry in a ventilated place, let the acetone volatilize completely, and then press into a ring (18mm OD×9mm I...

Embodiment 3

[0029] Pickling 25g sendust powder in 1% dilute hydrochloric acid aqueous solution for 15min, washing the residual liquid on the surface of sendust powder with cold water to obtain 20g washed sendust powder; weigh 5g NaOH and dissolve in 200ml distilled water , weigh 100gNaNO 2and 10gNa 3 PO 4 Dissolve in 40ml of distilled water, pour the mixture of the two into a three-necked flask and heat to boiling, add 20g of cleaned sendust and stir for 120min; leave to cool, filter, and filter the cake with cold water, hot water and absolute ethanol in turn Wash each for 3 times; put the sample in a vacuum drying oven at 50°C and dry for 1 hour to obtain 20 g of pretreated sendust powder; mix and dissolve 20 g of the pretreated sendust powder with 0.1 g of phenolic resin and 5 ml of acetone, and ultrasonically After dispersion, let the acetone volatilize in a ventilated place and then press it into a ring (18mm OD×9mm ID×3mm tall) at 25°C and 1000MPa; heat-treat the ring at 650°C in n...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com