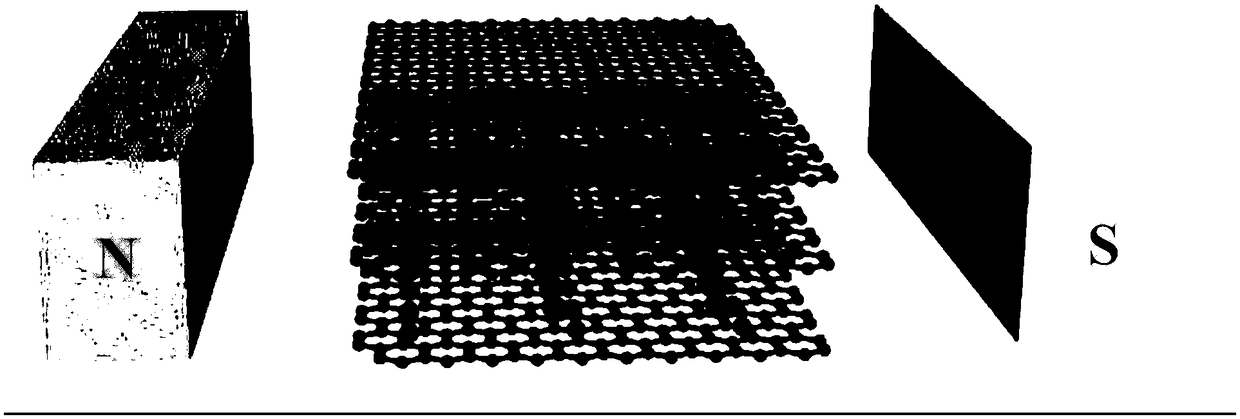

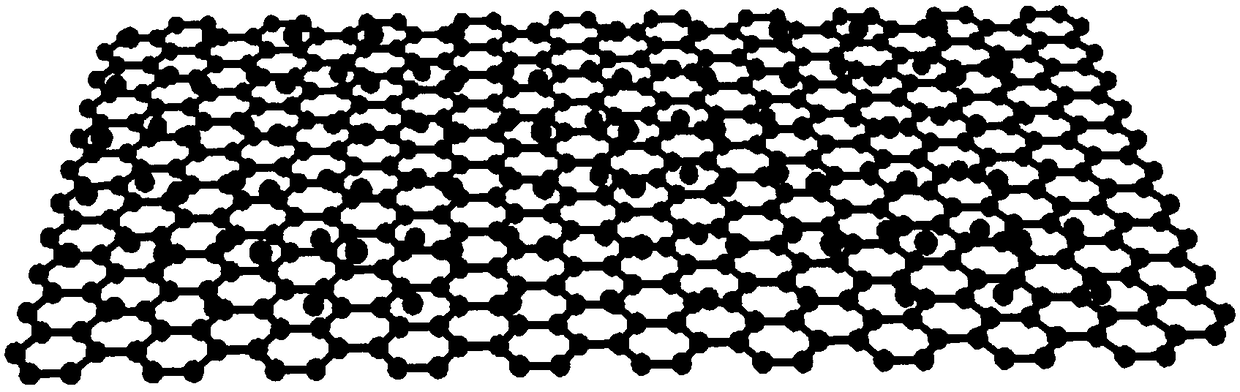

Novel method for preparing magnetic oxide and perpendicular graphene array composite and application thereof to supercapacitor

A graphene array and magnetic oxide technology, which is applied in the manufacture of hybrid capacitor electrodes, hybrid/electric double layer capacitors, etc., can solve the problem that the specific capacitance is only 230, only a few hundred Faradays per gram, etc., to improve the specific capacitance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] Embodiment 1 (the manganese base oxide with ferromagnetism is La 0.67 Sr 0.33 MnO 3 )

[0021] First, use graphene oxide with a sheet diameter in the range of 200-2000nm as the raw material, weigh graphene oxide and add deionized water to make a solution with a graphene concentration of 1mg / l, ultrasonically disperse for 2-20h, and the ultrasonic power is 500W. Stir the solution. Take the supernatant of the configured graphene oxide solution, dilute it into a solution of 0.5 mg / L, and add ferromagnetic La 0.67 Sr 0.33 MnO 3 The nanopowder was ultrasonically dispersed for 2 hours, and then stirred for 3 days to obtain a uniform dispersion solution, and the mass ratio of graphene oxide and nanopowder in the solution was in the range of 0.2. Then, transfer the solution to a round-bottomed flask, add hydrazine hydrate therein, the mass ratio of hydrazine hydrate to graphene oxide is 0.7-1, and then reflux in an oil bath at a temperature of 95° C. for 8 hours. Then fi...

Embodiment 2

[0023] Embodiment 2 (with magnetic iron base oxide is La 0.67 Sr 0.33 FeO 3 ):

[0024] First, use graphene oxide with a sheet diameter in the range of 200-2000nm as the raw material, weigh graphene oxide and add deionized water to make a solution with a graphene concentration of 1mg / l, ultrasonically disperse for 2-20h, and the ultrasonic power is 500W. Stir the solution. Take the supernatant of the configured graphene oxide solution, dilute it into a solution of 0.5 mg / L, and add ferromagnetic La 0.67 Sr 0.33 FeO 3 The nano-powder is ultrasonically dispersed for 0.5h, and then stirred for 3 days to obtain a uniform dispersion solution, and the mass ratio of graphene oxide and nano-powder in the solution is in the range of 0.2. Then, transfer the solution to a round-bottomed flask, add hydrazine hydrate therein, the mass ratio of hydrazine hydrate to graphene oxide is 0.7-1, and then reflux in an oil bath at a temperature of 95° C. for 8 hours. Then filter, wash, and v...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com