Preparation method for directly growing highly-doped yttrium iron garnet film on silicon

A yttrium iron garnet, highly doped technology, applied in the direction of single crystal growth, crystal growth, single crystal growth, etc., can solve the problem of low content of rare earth element doping in yttrium iron garnet magneto-optical films, restricting the magneto-optical effect of materials, etc. problem, to achieve the effect of enhancing the magneto-optical performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] In order to allow those skilled in the art to better understand the technical solutions of the present invention, the present invention will be further described with reference to the accompanying drawings.

[0027] In order to obtain a highly doped yttrium iron garnet film, the following four groups of embodiments are designed;

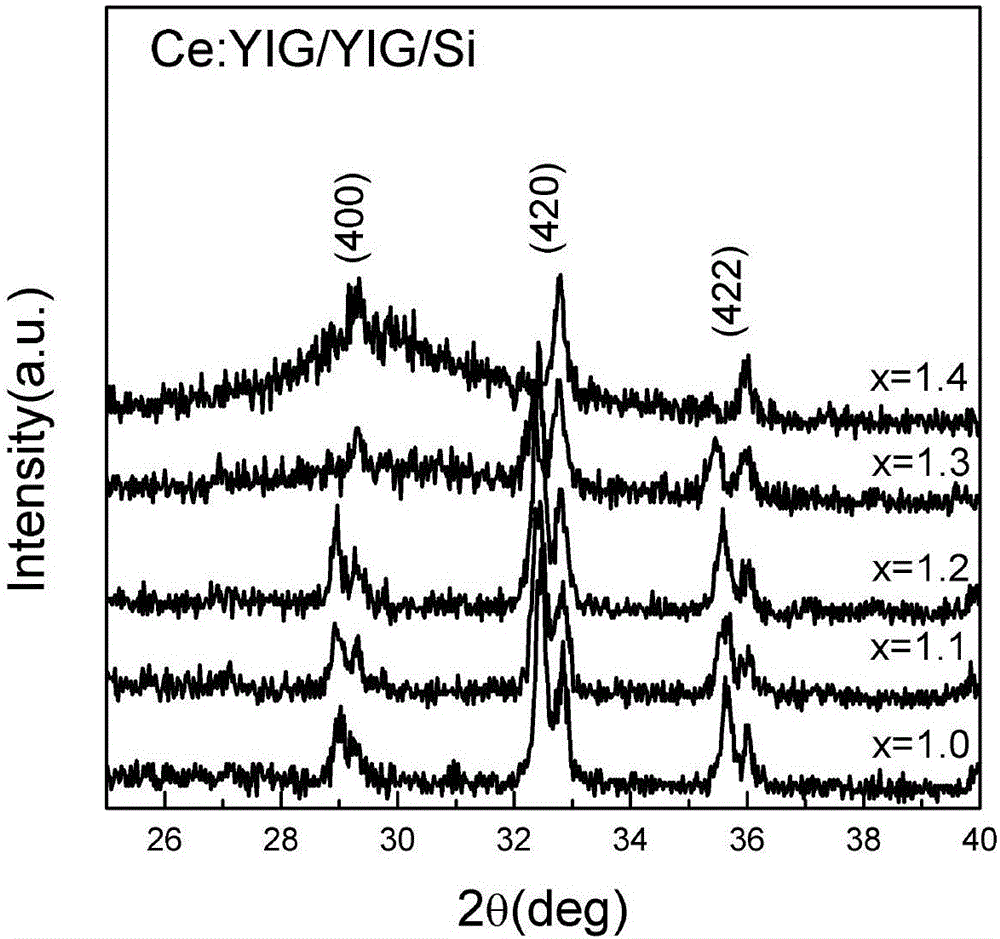

[0028] The first group: Ce: YIG (x = 1.0, 1.1, 1.2, 1.3, 1.4) film preparation; (reference sample)

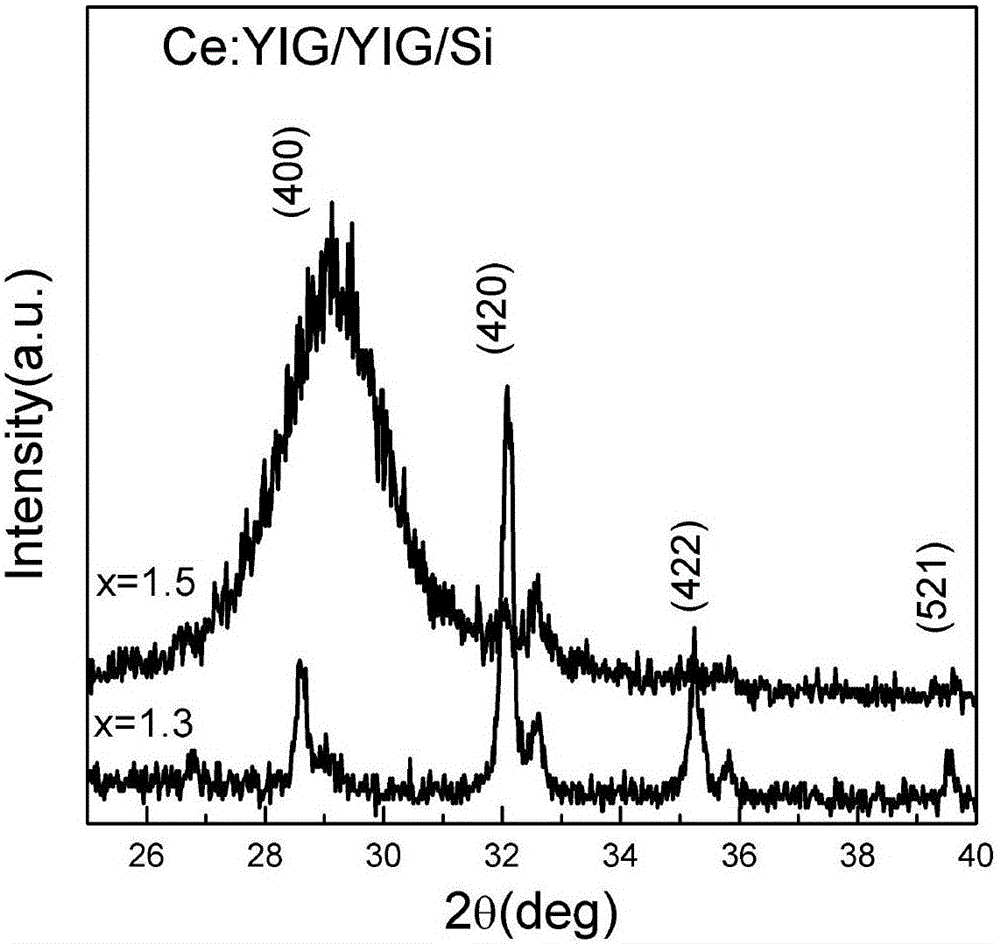

[0029] The second group: preparation of Ce:YIG (x=1.3, 1.5) film;

[0030] The third group: preparation of Ce:YIG (x=1.4) film;

[0031] The fourth group: preparation of Ce:YIG (x=1.5) film.

[0032] The x mentioned above is the chemical formula Ce x Y 3-x Fe 5 O 12 Where represents Ce atom content, 1≤x≤3.

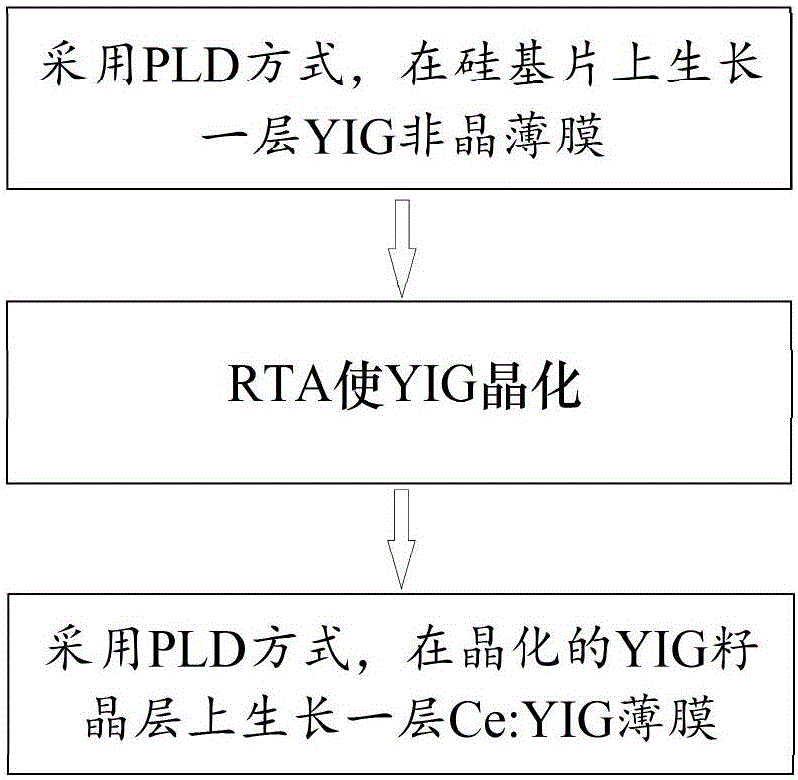

[0033] Please refer to the attached Figure 1-6 The object of the present invention is to provide a method for preparing yttrium iron garnet film with high rare earth doping and strong magneto-optical effect grown on silicon. Taking Ce doped YIG as a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com