High-aluminum terbium aluminum gallium garnet magneto-optical crystal and preparation method and application thereof

A gallium garnet, terbium aluminum technology, applied in crystal growth, chemical instruments and methods, optics, etc., can solve the problems of low aluminum content, difficult crystal growth, unsatisfactory crystal quality, etc., to reduce melt component segregation, The preparation method is scientific and reasonable, and the price is low.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

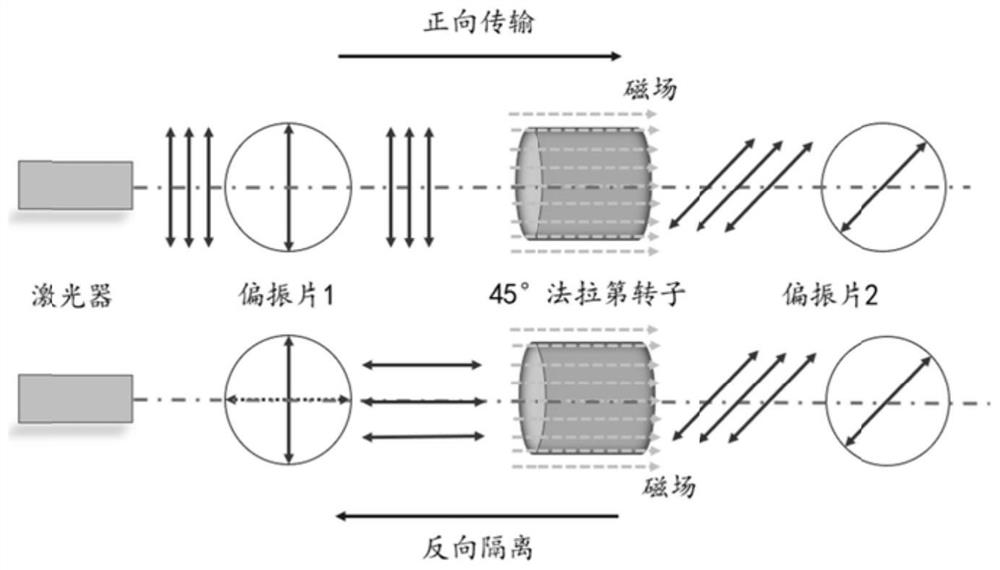

Problems solved by technology

Method used

Image

Examples

Embodiment 1

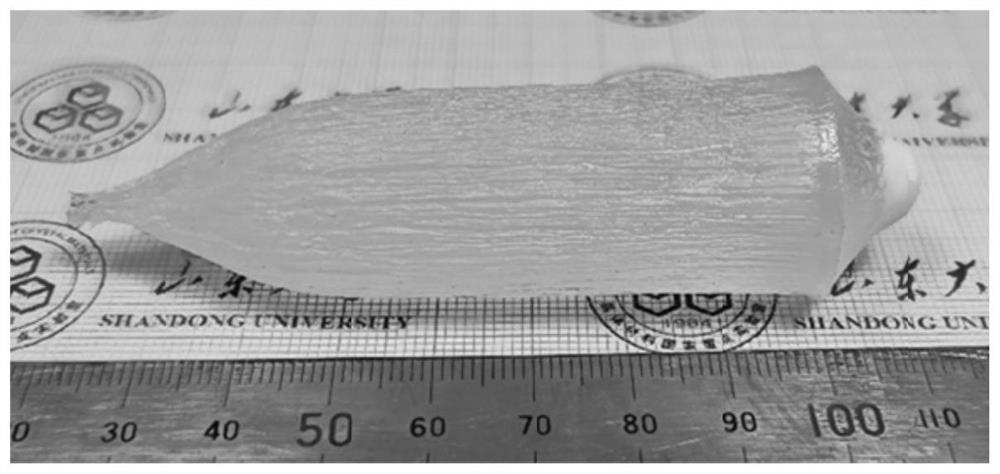

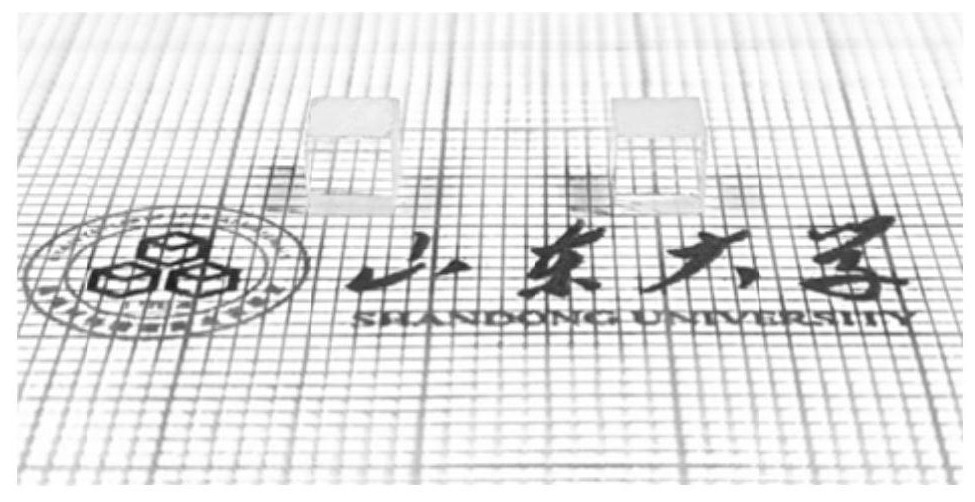

[0052] Example 1: TAGG (x=1.75) crystal Tb 3 Al 1.75 Ga 3.25 O 12 grow

[0053] (1) Synthesis of polycrystalline materials by solid-phase sintering

[0054] Raw material Tb 4 O 7 , Al 2 O 3 , Ga 2 O 3 The purity is 99.99%. According to the stoichiometric ratio of Tb 3 Al 1.75 Ga 3.25 O 12 Weigh the raw material, considering Ga 2 O 3 The volatilization and decomposition of 2 O 3 If the excess amount is 2wt.%, put the raw materials into the mixing bucket and mix them thoroughly. The mixing time is 48h. Put the evenly mixed material into a mold and press it into a cylindrical shape, put it into a corundum crucible, and sinter it in a sintering furnace at 1350 ℃ for 36h. The polycrystalline material of TAGG (x=1.75) can be obtained

[0055] (2) crystal growth by pulling method

[0056] Put the sintered polycrystalline material into the iridium crucible (the crucible has been placed in the prepared temperature field), align the center, install the temperature fi...

Embodiment 2

[0057] Example 2: TAGG (x=2) crystal Tb 3 Al 2 Ga 3 O 12 grow

[0058] As described in Example 1, the difference is:

[0059] (1) Synthesis of polycrystalline materials by solid-phase sintering

[0060] According to the stoichiometric ratio of Tb 3 Al 2 Ga 3 O 12 Weigh the raw materials to obtain TAGG (x=2) polycrystalline material.

[0061] (2) crystal growth by pulling method

[0062] During the growth process, the rotation speed was 15 rpm, and the cooling rate was 40 °C / h.

Embodiment 3

[0063] Example 3: TAGG (x=3) crystal Tb 3 Al 3 Ga 2 O 12 grow

[0064] As described in Example 1, the difference is:

[0065] (1) Synthesis of polycrystalline materials by solid-phase sintering

[0066] According to the stoichiometric ratio of Tb 3 Al 3 Ga 2 O 12 Weigh the raw materials to obtain TAGG (x=3) polycrystalline material.

[0067] (2) crystal growth by pulling method

[0068] During the growth process, the pulling speed was 1 mm / h, the rotational speed was 30 rpm, and the cooling rate was 40 °C / h.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| transmittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com