A preparation method of a soft magnetic composite material with high permeability

A soft magnetic composite material, high permeability technology, applied in the direction of inorganic material magnetism, inductance/transformer/magnet manufacturing, electrical components, etc., can solve the problems of low permeability and high frequency loss, and achieve low hysteresis loss , The effect of reducing the magnetic circuit reluctance and demagnetizing field, reducing the magnetic circuit reluctance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] 1) Raw material preparation

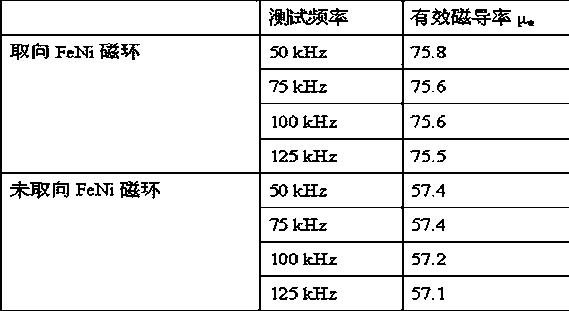

[0046] The main magnetic phase is Fe-Ni powder; the interface insulating phase is MgO and magnesium zinc ferrite; the magnetic oxide is synthesized by hydrothermal method;

[0047] 2) Insulation coating of soft magnetic alloy powder

[0048] After the Fe-Ni powder is passivated, it is fully mixed with the interface insulating phase to realize the insulation coating of the soft magnetic alloy powder; the mass fraction of Fe-Ni is 98wt.%; the mass fraction of the interface insulating phase is 2wt.%. Oxide mass fraction 1.2wt.%;

[0049] 3) Preparation of orientation magnets by hot pressing and thermal deformation

[0050] The blank is obtained through a hot-pressing process, and the hot-pressing temperature is 560°C; the blank is subjected to pressure deformation through a thermal deformation process, and the pressure direction is perpendicular to the plane of the magnetic ring, the thermal deformation temperature is 800°C, and the thermal ...

Embodiment 2

[0054] 1) Raw material preparation

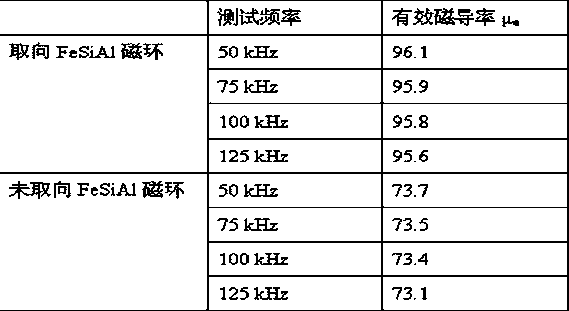

[0055] The main magnetic phase is Fe-Si-Al powder; the interface insulating phase is Al 2 o 3 and planar hexagonal ferrite; magnetic oxides are synthesized by hydrothermal method;

[0056] 2) Insulation coating of soft magnetic alloy powder

[0057] After the Fe-Si-Al powder is passivated, it is fully mixed with the interfacial insulating phase to realize the insulating coating of the soft magnetic alloy powder; the mass fraction of Fe-Si-Al is 98.9wt.%; the mass fraction of the interfacial insulating phase is 1.1wt.%; magnetic oxide mass fraction 0.5wt.%;

[0058] 3) Preparation of orientation magnets by hot pressing and thermal deformation

[0059] The blank is obtained through a hot-pressing process, and the hot-pressing temperature is 600°C; the blank is subjected to pressure deformation through a thermal deformation process, the pressure direction is perpendicular to the plane of the magnetic ring, the thermal deformation temperatu...

Embodiment 3

[0063] 1) Raw material preparation

[0064] The main magnetic phase is Fe powder; the interface insulating phase is glass powder and manganese zinc ferrite; the magnetic oxide is synthesized by hydrothermal method;

[0065] 2) Insulation coating of soft magnetic alloy powder

[0066] After the Fe powder is passivated, it is fully mixed with the interface insulating phase to realize the insulating coating of the soft magnetic alloy powder; the mass fraction of Fe is 97wt.%; the mass fraction of the interface insulating phase is 3wt.%; the mass fraction of magnetic oxide 2wt.%;

[0067] 3) Preparation of orientation magnets by hot pressing and thermal deformation

[0068] The blank is obtained through a hot-pressing process, and the hot-pressing temperature is 660°C; the blank is subjected to pressure deformation through a thermal deformation process, the pressure direction is perpendicular to the plane of the magnetic ring, the thermal deformation temperature is 600°C, and th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Heat distortion temperature | aaaaa | aaaaa |

| Heat distortion temperature | aaaaa | aaaaa |

| Heat distortion temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com