Material distributing method and device of circular cooler

A technology of material distributing device and ring cooler, which is applied in the direction of processing discharged materials, furnaces, lighting and heating equipment, etc., and can solve the problem of poor segregation effect of the material distribution device of the ring cooler, large power consumption of the blower motor, and cooling effect of the ring cooler To achieve the effect of simple structure, easy production and installation, and fast laying speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

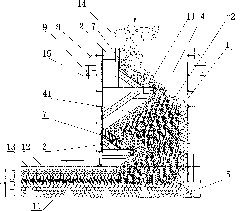

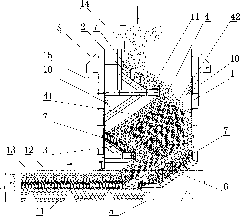

[0024] figure 1 It shows an embodiment of laying sintered ore on the circulating cooler trolley 5 by using the circulating cooler distribution method of the present invention. It is layered to pave the sintered ore on the circulating cooler trolley 5. Granular sinter 11 is mainly used, the sinter laid in the middle layer is mainly small-grain sinter 12, and the sinter laid on the top layer is mainly medium-grain sinter 13. Among them, the particle size of the large particle size sinter 11 is 40 mm to 150 mm, the particle size of the medium particle size sinter 13 is 10 mm to 40 mm, and the particle size of the small particle size sinter 12 is less than 10 mm. The thickness of the large, medium, and small grain size zones is related to the grain composition of the input mixed sinter, and is variable. Generally speaking, the bottom sinter thickness L1 mainly composed of the large grain size sinter 11 is 400mm~600mm, and the small The thickness L2 of the middle layer sinter with t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com