Shallow groove segregation structure and forming method thereof

A technology of isolation structure and shallow trench, which is applied in the direction of electrical components, semiconductor/solid-state device manufacturing, circuits, etc., can solve the problems of unstable performance of semiconductor devices, poor isolation effect of shallow trench isolation structure, etc., and achieve stable working performance, Improved isolation effect and stable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

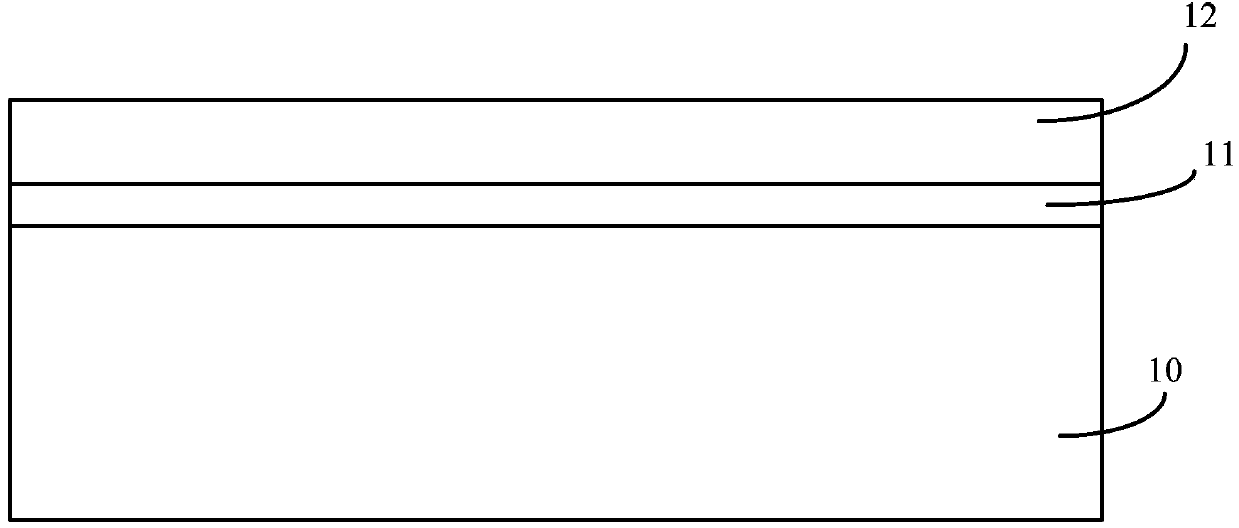

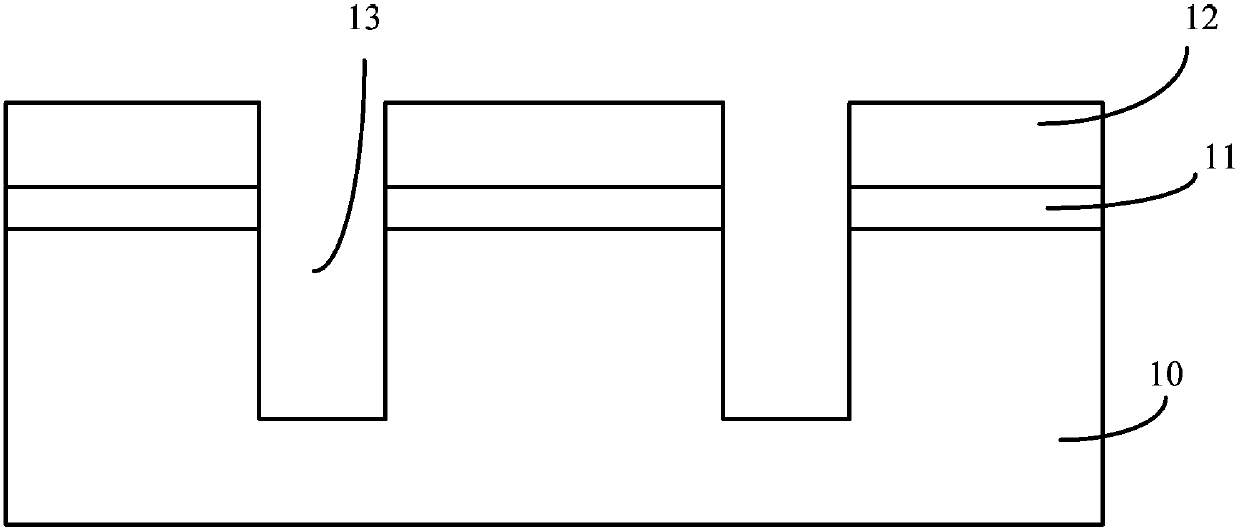

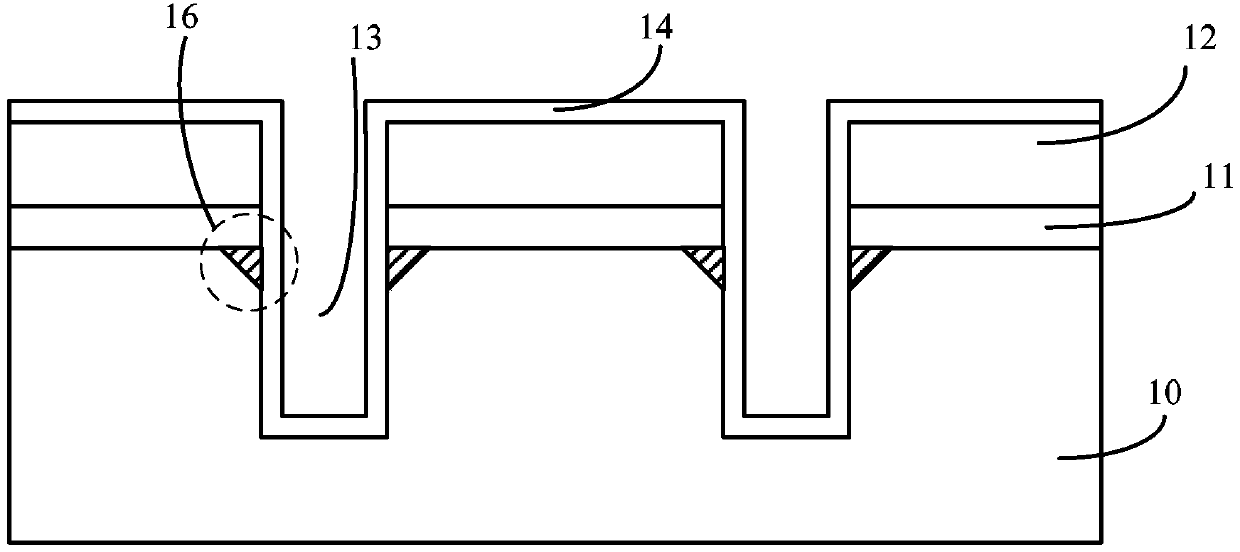

[0044] As described in the background, the isolation effect of the shallow trench isolation structure formed in the prior art is poor, which leads to unstable performance of semiconductor devices isolated using the shallow trench isolation structure.

[0045] In order to meet the development requirements of integration and miniaturization of the prior art, the size of semiconductor devices is getting smaller and smaller, so that the distance between the shallow trench isolation structures isolating the semiconductor devices is also reduced accordingly; however, due to the shallow The distance between the trench isolation structures is reduced, so that the implanted ions are more likely to diffuse into the shallow trench isolation structure when the semiconductor device isolated by the shallow trench isolation structure is subjected to an ion implantation process for doping the well region , so that the turn-on voltage of the semiconductor device formed subsequently is reduced, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com