Aluminum-zinc multi-component alloy-containing water-based epoxy coating for anti-corrosive treatment of submarine oil and gas pipelines and preparation method of water-based epoxy coating

A technology of water-based epoxy coating and multi-element alloy, applied in the field of coatings, can solve the problems of reducing the service life and safety of submarine steel pipes, preventing the intrusion of small molecule corrosive media, affecting the physical shielding performance of coatings, etc., and achieving enhanced electrochemical corrosion resistance and chemical corrosion performance, reduce the generation of free phase, and the effect of excellent anti-corrosion performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] 30g of aluminum-zinc multi-element alloy water-based epoxy coatings for anticorrosion treatment of submarine oil and gas pipelines, the coatings are composed of the following components by mass percentage:

[0035]

[0036] The film-forming substance is composed of 20% water-based phenolic epoxy resin and 14% water-based polyurethane according to the mass percentage; the pigment and filler include aluminum-zinc multi-element alloy powder; the solvent is deionized water.

[0037] Pigments and fillers are prepared from the following components according to the total mass percentage of the coating:

[0038]

[0039]

[0040] The aluminum-zinc multi-element alloy powder is scaly aluminum-zinc multi-element alloy powder, with an average sheet diameter of about 16 μm, a sheet thickness of about 0.4 μm, and an aspect ratio of 40.

[0041] The composition of the scale-shaped aluminum-zinc multi-element alloy powder is as follows according to the total mass percentage o...

Embodiment 2

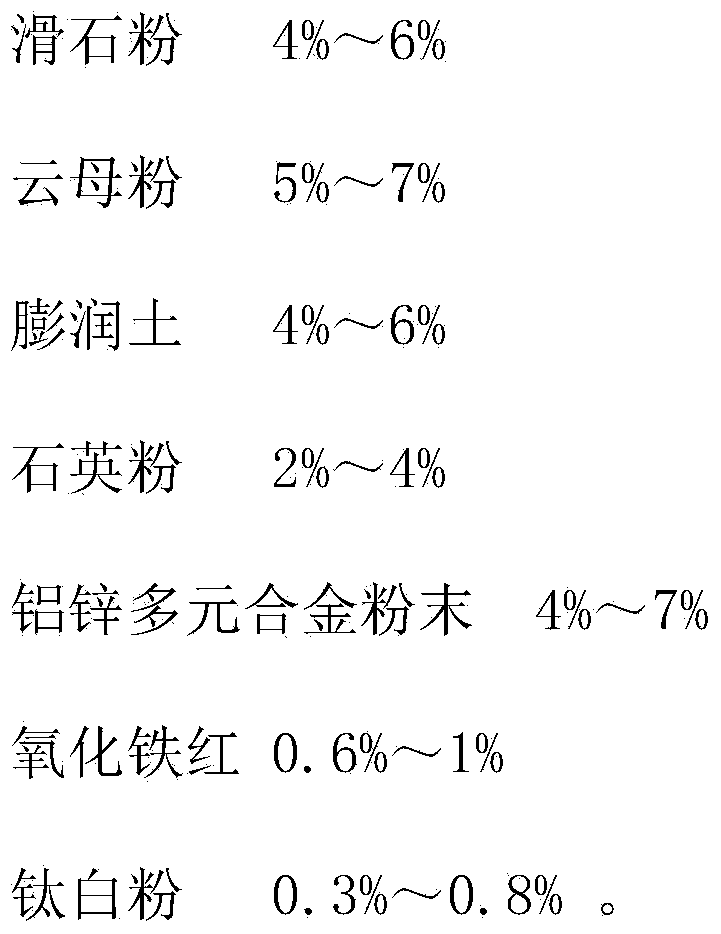

[0053] 50g of aluminum-zinc multi-element alloy water-based epoxy coatings for anticorrosion treatment of submarine oil and gas pipelines, the coatings are composed of the following components by mass percentage:

[0054]

[0055] Wherein, the film-forming substance is composed of 16% of water-based phenolic epoxy resin and 14% of water-based polyurethane according to the mass percentage; the pigment and filler include aluminum-zinc multi-element alloy powder; and the solvent is deionized water.

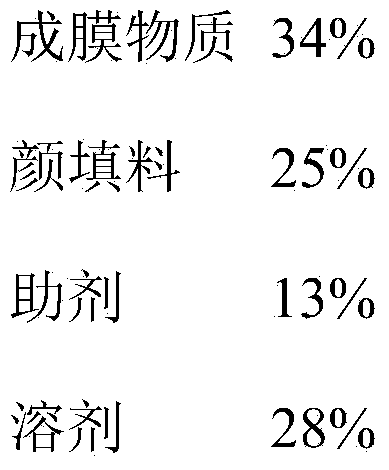

[0056] Pigments and fillers are prepared from the following components according to the total mass percentage of the coating:

[0057]

[0058] The aluminum-zinc multi-element alloy powder is scaly aluminum-zinc multi-element alloy powder, with an average sheet diameter of about 14 μm, a sheet thickness of 0.4 μm, and an aspect ratio of about 60.

[0059] The composition of the scale-like aluminum-zinc multi-element alloy powder is based on the total mass percentage of the coat...

Embodiment 3

[0071] 100g of aluminum-zinc multi-element alloy water-based epoxy coatings for anticorrosion treatment of submarine oil and gas pipelines, the coatings are composed of the following components by mass percentage:

[0072]

[0073] Wherein, the film-forming substance is composed of 16% of water-based phenolic epoxy resin and 14% of water-based polyurethane according to the mass percentage; the pigment and filler include aluminum-zinc multi-element alloy powder; and the solvent is deionized water.

[0074] Pigments and fillers are prepared from the following components according to the total mass percentage of the coating:

[0075]

[0076] The aluminum-zinc multi-component alloy powder is a scaly aluminum-zinc multi-component alloy powder, with a sheet diameter of about 17 μm, a sheet thickness of 0.3 μm, and an aspect ratio of about 35.

[0077] The composition of the scaly aluminum-zinc multi-element alloy powder is as follows: Al: 3% (3g), Si: 0.2% (0.2g), rare earth:...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| aspect ratio | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com